Underwater Radiated Noise: What’s Missing for Design?

We all acknowledge the environmental impact of Underwater Radiated Noise (URN) from ships, and the challenges it poses for shipping companies and shoreside organizations. While noise is produced by drive systems and other mechanical components, noise specifically from the propeller can be particularly damaging since it is the source with the greatest URN strength and propagation distance. Mitigating this type of URN production is also of timely interest, as certain whale populations – that are at critical risk of extinction – are particularly susceptible to the effects of propeller-driven noise.

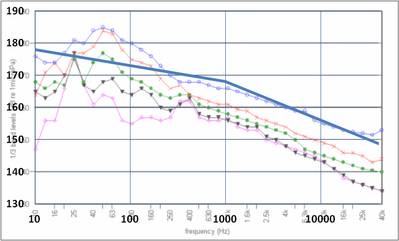

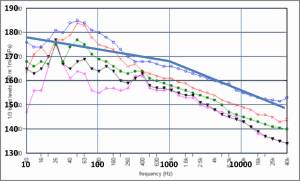

Why is propeller-driven noise so important? To answer this, let’s consider the noise spectrum for a typical modern bulk cargo ship [1]. The plot in Figure 1 below shows source levels (“sound pressure levels”, in dB) versus the frequency of the noise (in Hz). The full spectrum that we see in the plot includes noise produced by a number of excitation sources – propellers, engines, gear sets, other machinery, even from external water flow around the ship. The rich noise environment caused by all of those sources typically is represented as an approximation using what is known as a “1/3 octave bandwidth spectral analysis”, which is a big name for the integration of total noise energy into frequency bands for a more easily communicated picture.

Figure 1 – Typical 1/3 octave band URN spectrum. Image courtesy HydroComp

Figure 1 – Typical 1/3 octave band URN spectrum. Image courtesy HydroComp

The curves with marker points are measured values at different ship speeds and the heavy blue line is the “DnV Silent E” notation, a contemporary noise threshold criterion. You’ll note that at all but the slowest speeds, the ship exceeds the criterion in the frequency range of more-or-less 20 to 100 Hz. The reason why propeller-driven noise is so important is twofold – a) the energy in this frequency band is principally caused by the propeller (by propeller cavitation, actually, versus the various other noise sources) and b) whale populations (particularly those currently at risk) are most affected by noise in this band.So the spectrum tells us that we need to make the ship quieter. But it does so after the ship has launched. After all of the expense in design and manufacture has been spent. After you are committed to a business plan for the ship.

It should be obvious by now that the best time to ensure quiet operation and regulatory compliance is during the design phase. Model testing is an option, but that is an expensive and time-consuming undertaking. Analysis by CFD is still evolving for the prediction of URN, and is limited to the domain of technical specialists. As a developer of engineering tools for various aspects of hydrodynamic, propulsion system, and propeller performance simulation, as well as over three decades of experience in propeller design and analysis, I am concerned that there are no tools currently available and easily accessible to naval architects and designers for the engineering prediction of propeller-driven noise.

URN assessment for design

The writing is on the wall. URN is expected to soon be formally classified as a pollutant, with all of the regulation and mitigation requirements that come with it. Prediction of, and the design response to, URN must become part of the ship design process from its earliest stages to post-delivery assessment – no different from stability, seakeeping, or making speed. Therefore, I would like to propose a path to that end.

Recently, HydroComp has been called on to bring subject matter expertise in propeller performance to a number of professional societies and international regulatory agencies working on the mitigation and regulation of URN. Simultaneously, we have an internal R&D project to assess the potential for suitable simplified models to reliably predict propeller-driven URN. Both of these activities have led us to propose a preliminary calculation and assessment framework suitable for noise prediction and mitigation during design.

The framework has the following attributes:

Predictions are for critical noise sources, such as from tip vortex and blade cavitation, as well as non-cavitating pressure pulses.

Cause-and-effect relationships are built to conform to the underlying physics, such as for the relationships between noise and specific cavitation characteristics.

Required data for the prediction models use only significant and easily-defined characteristics of propeller geometry, thrust/power loading, stern shape parameters, and ship operation.

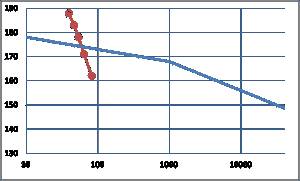

Design evaluation of URN would then take on a much simpler form of the above spectrum. The graph in Figure 2 below illustrates how a propeller-driven noise source evaluated by the framework models might be plotted against an agency’s noise criterion. The new red line plots the speed-dependent prediction results from the developed framework equations, and the intersection thus clearly indicates the critical compliance speed. If a particular design variant does not meet the criterion, the prediction model itself actually provides guidance to the engineers regarding how the different parameters – propeller, ship stern, operation – might be altered to comply.

Figure 2 – Simplified prediction of key propeller-driven URN metrics. Image courtesy HydroComp

Figure 2 – Simplified prediction of key propeller-driven URN metrics. Image courtesy HydroComp

There is a further technical benefit with the use of this framework for design assessment of noise. Propeller noise tends to be found at specific frequencies related to the RPM and blade count of the propeller. Peak sources for this “blade pass frequency” and its acoustic multiples can be lost in the “1/3 octave” approximation but would be captured by the prediction models in this framework.

A model for regulatory compliance

A final opportunity for this framework is as a foundation for regulatory compliance. Compliance based on testing ships for their generated noise has a number of potential shortcomings, including a) uncertainty due to the corrections needed to convert a test reception noise into a common source noise (for proper ship-to-ship comparisons), b) the likelihood that certain sites would generate more favorable results leading to “gaming” of the compliance, c) that tests are a snapshot observation which may or may not reflect a highest noise condition, and as noted above, d) tests occur after “the ship has sailed” at which point mitigation may be impractical.

The use of simplified models for regulatory compliance is not new. We already have many examples of rules-based regulation using models of similar form, including Class society rules, EEDI (and variants), and safety-of-life rules (such as for intact and damaged stability) from coast guards and national agencies. For example, URN rule implementation could follow what is already used for other regulated propeller attributes, such as the various Class rules for sufficient blade strength. These are relatively simple equations using a cantilever beam as the underlying physics-based framework. Rules for a “noise metric” could employ the physics of cavitation and pressure pulse development as its underpinning, with the rule’s data variables being those significant and easily-defined characteristics noted above.

The time is now to incorporate URN assessment in design planning

The shipping industry will certainly be subject to near-term regulation of underwater radiated noise, and ships that exceed noise restrictions will require costly and schedule-disrupting mitigation. However, I believe that there is still time for shipping companies and other stakeholders to help guide how URN assessment is to be handled both during design and post-delivery, as well as for regulatory compliance. It is my opinion that the ability for the design and shipping community to easily conduct URN assessment for new designs and retrofits – as is currently done for many ship performance parameters – is a critical missing piece of the larger and notable objectives of reducing the environmental damage caused propeller-driven underwater radiated noise.

[1] Arveson, P.T. and Vendittis, D.J. “Radiated noise characteristics of a modern cargo ship”, Journal of the Acoustical Society of America, Vol. 107, No. 1, 2000.