Study: Compressed Hydrogen Beats Ammonia on Capital and Energy Efficiency

Provaris Energy has completed a study for bulk-scale hydrogen export and import compression facilities that it says confirms the viability the low energy use and low capital of Provaris’ compressed hydrogen supply chain for regional marine transport of hydrogen in gaseous form.

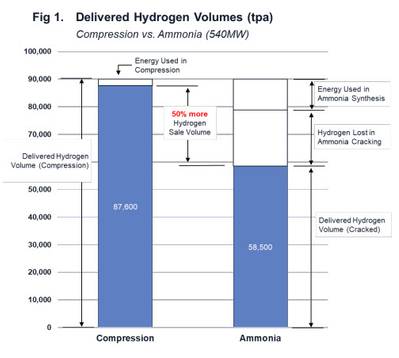

The study, the fourth in a series of techno-economic studies developed by Provaris, was based on a 540MW capacity reservation export site, producing 10 tonnes of hydrogen per hour (equivalent to 87,000 tpa); with an intra-Europe shipping distance of 1,000 nautical miles using the company’s H2Neo carrier to deliver gaseous hydrogen to the customer at 70 barg.

A high pressure compressor OEM supported the preparation of the study with the selection of optimal compression equipment to ensure the project's feasibility.

Key outcomes:

• Reconfirmed low energy use with only ~1.5 kWh per kg of hydrogen required for storage and loading compression (export terminal), and only 0.2 kWh/kg for unloading compression (import terminal).

• Compression energy use represented only ~2.8% (15MW) of all power requirement for the export site, with the remaining 97.2% (525MW) available for hydrogen production (via electrolysis).

• Concludes that compression has up to five times less energy use than required for ammonia synthesis (7.5 kWh/kg H2 or 65MW), leaving only 470MW available for electrolysers after ammonia synthesis.

• Capital cost of compression facilities was €120 million, representing less than 7% of the total capex of the hydrogen supply chain.

• Low energy use of compression, with little or no hydrogen losses, results in ~50% greater hydrogen volumes delivered to the customer when compared to ammonia supply.

• Supported by the study scope and outcomes, compression’s superior capital and energy efficiency could result in a ~20% lower delivered price at €6/kg compared to regional supply ammonia post cracking back to hydrogen at €7.4/kg.

• Europe’s recent H2Global and EU Hydrogen Bank auction results allocating €1.1 billion funding to green ammonia and hydrogen projects demonstrated a hydrogen supply cost range of €6-10/kg further highlighting the competitiveness of compression.

Garry Triglavcanin, Product Development Director at Provaris, said: “The Concept Design Study reconfirmed the superior energy efficiency and low capital cost associated with compression for marine transportation of hydrogen. It is pleasing to receive detailed costings and equipment selection from the Compressor OEM, supporting our development case in Europe.

“This study has increased our confidence and understanding that many regional-European sites with a material level of renewable power reservation can significantly benefit from compression, when compared to the alternative of converting hydrogen into ammonia for marine transport. The benefits of compression include delivering more hydrogen in volume, using less capex, and boosting the financial returns to the producer whilst maintaining a highly competitive delivered cost to the customer.”

The results of the study will be used as a basis for the development of site-specific compression facilities for both export terminal feasibility studies for sites identified in Norway and the Nordics and import site locations such as Port of Rotterdam. The planned developments are part of a collaboration between Provaris and Global Energy Solutions.

Earlier this year, Provaris Energy and Norwegian Hydrogen signed an MoU with Uniper Global Commodities aimed at strengthening co-operation in developing hydrogen supply chains from Norway and other potential Nordic sites, to import locations in North-Western Europe. Development activities with Uniper also include the review of multiple import site locations where compression will be required.