Japanese Firms Use Laser Tech for Rust and Coating Removal from Vessels

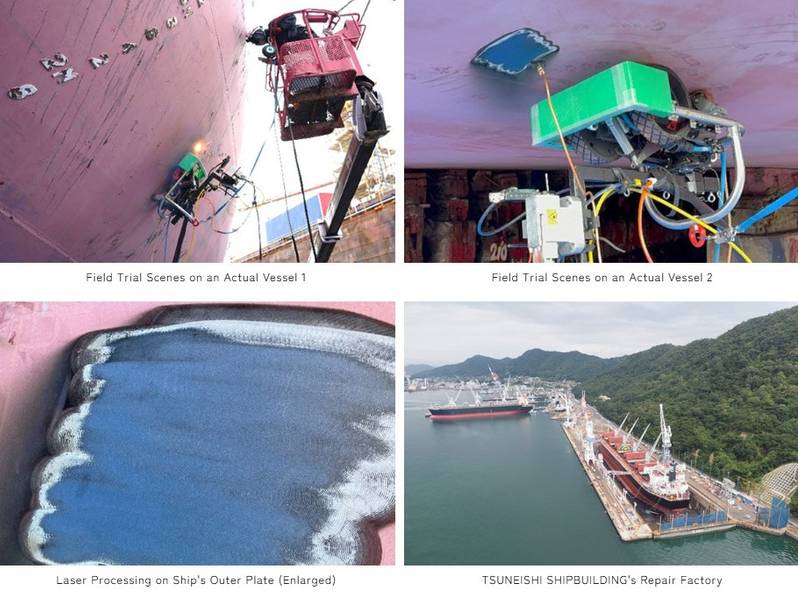

Mitsui O.S.K. Lines (MOL), MOL Drybulk, Furukawa Electric, and Tsuneishi Shipbuilding, have tested the InfraLaser system on the outer hull of an actual vessel, successfully stripping down rust and coatings with industrial laser technology.

Furukawa Electric, with the cooperation of MOL and MOL Drybulk, has been developing a rust and coating removal system for onboard maintenance since 2021, utilizing the surface treatment solution InfraLaser based on technology cultivated in industrial lasers.

Since 2022, Furukawa Electric and Tsuneishi Shipbuilding have been conducting demonstration experiments aimed at the development of the same system for ship repairs.

Through the development of InfraLaser systems, the partners aim to reduce the environmental impact and improve working conditions in ship repairs. In the future, they also plan the automation of the processes.

During ship repairs, rust and coatings are removed for hull inspection and repainting. However, the current sandblasting method, which removes rust and coatings by blasting abrasive materials against the surface, scatters waste materials and removed paint as debris, necessitating recovery efforts.

By replacing this with a laser blasting method that generates minimal waste, dust, and noise, we expect to reduce environmental impact and improve occupational health.

According to the companies, lasers differ from conventional methods in that they do not generate reaction force, resulting in no recoil during irradiation.

MOL Group and Tsuneishi Shipbuilding, recognizing the potential of utilizing InfraLaser for ship repairs, initiated discussions on collaborative creation and development of a laser blasting system for ship maintenance and repairs.

Field Trial Confirms Effectiveness of Laser Tech

(Credit: MOL)

(Credit: MOL)

By applying the metal processing (welding, cutting, surface treatment, etc.) technology that Furukawa Electric has cultivated over many years in industrial laser to the optimization of irradiation conditions for rust and paint removal in the undercoating of ships, the partners aim to develop a system that minimizes the impact on the object and reduces the environmental burden.

In the field trial, Tsuneishi Shipbuilding provided feedback for use in shipbuilding and ship repair, and MOL and MOL Drybulk provided development support and feedback as ship operators and managers.

These will be reflected in the development of the InfraLaser system and optimized into a shape and specifications suitable for use in real environment.

As the first effort by the four companies, the field trial was conducted in December 2024 on a ship operated by MOL, confirming the effectiveness of the laser application of the system under development to the outer hull.

“Moving forward, we will accelerate the development of an innovative laser application system for ship repair that can replace the conventional sandblasting method for rust and paint removal and coating of ships. We will also continue to study the automation of the system by taking advantage of the laser's zero reaction force, aiming to labor saving and automate the ship maintenance and repair process,” the companies said.