A new fleet of pusher tugs and barges for Louis Dreyfus Company have recently begun construction in Brazil, all to customized designs from Robert Allan Ltd. of Vancouver, Canada. The vessels will transport bulk grain products on the Amazon River system, with an expected delivery in 2017.

The shallow-draft fleet includes:

- Three RApide 4000-Z3 class mainline pusher tugs (under construction at INACE shipyard in Fortaleza, Brazil)

- One RApide 2600-Z3 class pusher tug

- Three RApide 2000-Z2 class port-assist pusher tugs

- Sixty-four jumbo hopper barges (under construction at Estaleiro Rio Maguari in Belem, Brazil)

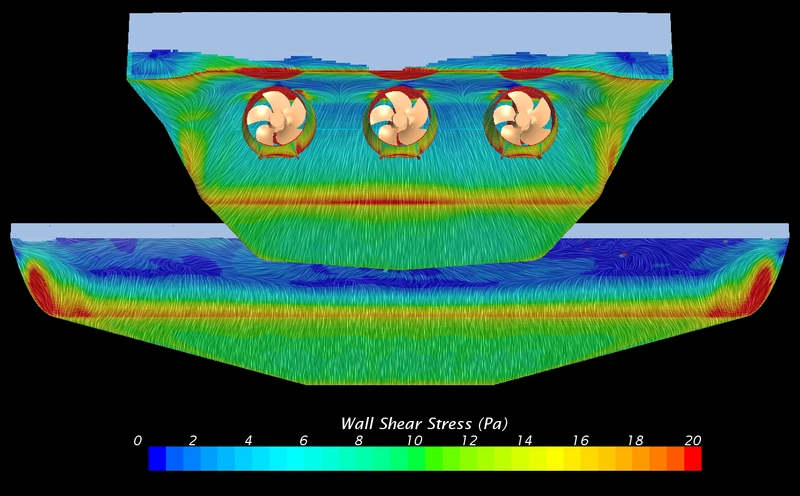

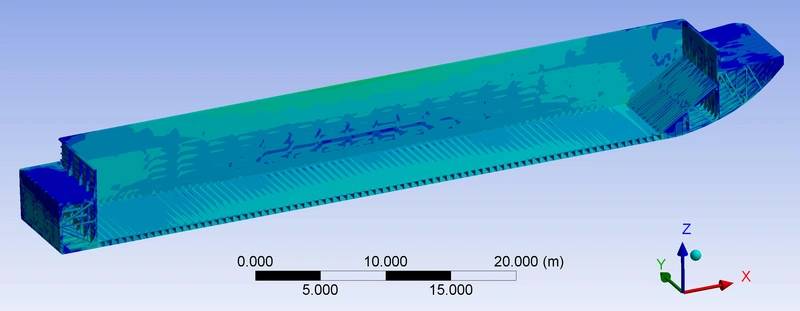

During the early phases of design, extensive Computational Fluid Dynamics (CFD) simulations were used to optimize the hull shapes to minimize total convoy resistance. In all cases, the z-drives are fitted in customized tunnels designed to optimize flow and propulsion efficiency while reducing draft. In conjunction, logistics modeling of the transportation system optimized the selection of vessels for the desired route and analyzed operational drafts and cargo throughput at various river levels. These studies aim to reduce the overall cost of transportation, while the design of the vessels increases the standards of safety, maneuverability and comfort in the river system.

All vessels are designed to meet ABS and Brazilian Flag State (NORMAM-02/DPC) requirements and provide the highest standards for crew comfort and safety. In each boat the wheelhouse provides maximum all-round visibility with a split forward control station providing unobstructed vision to the foredeck working area as well as to the convoy of barges ahead. Common equipment throughout the fleet will limit the number of spares required and ease with maintenance.

RApide 4000-Z3

The RApide 4000-Z3 class mainline pusher tugs will drive convoys of 16 barges, transporting the equivalent of up to 1,400 double trailer trucks (“B-Train”) in a single convoy, at a reduced overall cost and environmental impact, according to the designer. This represents the first of several new generation, high power, Z-drive pusher tugs designed by Robert Allan Ltd. for operation in this area. They join a number of smaller, modern Z-drive push boats already in service with other Brazilian operators. The RApide 4000-Z3 accommodates up to 18 people with a large galley and mess on the main deck. The deckhouse extends aft over the main propulsion equipment, which comprises three Wärtsilä 8L20 engines capable of operation on heavy fuel oil, driving Schottel SRP 1215 z-drive units. Two Caterpillar C18 diesel gensets are also fitted in the vessel's main machinery space at the main deck level, with an additional emergency/harbor genset located in a separate space.

- Length overall: 39.6 m

- Beam, moulded, extreme: 18 m

- Depth, moulded (hull): 4 m

- Minimum operating draft: 2.5 m

- Normal operating draft: 3 m

RApide 2600-Z3

The RApide 2600-Z3 will be used to propel smaller convoys and to provide assistance to larger convoys in shallow water. Accommodating up to 12 people, the deckhouse extends aft over the main propulsion equipment, which comprises three Caterpillar C18 diesel engines, each driving a Schottel SRP 330 Z-drive unit. The vessel's auxiliary machinery space, located below the main deck, hosts two Caterpillar C4.4 diesel gensets.

- Length overall: 25.6 m

- Beam, moulded, extreme: 10.5 m

- Depth, moulded (hull): 3 m

- Minimum operating draft: 2.1 m

- Normal operating draft: 2.3 m

RApide 2000-Z2

The RApide 2000-Z2 vessels will provide assistance at the loading and unloading ports and escort convoys through restricted regions. The deckhouse extends aft over two Schottel SRP 330 z-drive units, each driven by a Caterpillar C18 diesel engine located below the main deck. Electrical power is supplied by two Caterpillar C4.4 diesel gensets. The outfitting includes accommodation for 10 crew.

- Length overall: 19.5 m

- Beam, moulded, extreme: 9 m

- Depth, moulded (hull): 3.2 m

- Minimum operating draft: 2.2 m

- Normal operating draft: 2.5 m

Barges

Robert Allan Ltd. designed the corresponding box and rake barges to ABS River Rule requirements. Extensive FEA analysis of the structure was used to optimize the design for minimum steel weight while ensuring long service life during river operations. Sliding aluminum hatch covers ensure the cargo stays dry at all times.

- Length overall: 61 m

- Beam, moulded, extreme: 13.75 m

- Maximum operating draft: 4.5 m