Hydrex

Hydrex News

Marine Coatings and Breaking with Tradition

There’s a tendency for owners to stick with the coatings they are familiar with, but environmental concerns, particularly regarding marine biodiversity, are providing fresh opportunities for them to reconsider.Measuring hull coating performance from noon reports yields around 350 data points over a five-year docking cycle after including full loaded sailing days and excluding adverse weather days etc.But…

Hydrex Completes RoRo Bow Thruster Replacement in Rotterdam

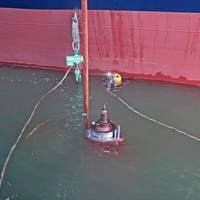

Last month a Hydrex team replaced the bow thruster of a 191-meter roro ship during the vessel’s stop in Rotterdam. Using one of the company’s workboats, the diver/technicians carried out the operation on-site.The team mobilized to the ship’s location on the workboat loaded with all the needed equipment. After the team set up a monitoring station, the divers started the operation with a detailed inspection of the bow thruster and tunnel.

Tech File: Hydrex Completes Mobile Stern Tube Seal Replacement

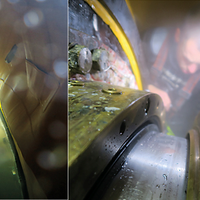

Hydrex mobilized diver/technician teams to vessels in the Netherlands and Australia to carry out stern tube seal replacements. In Flushing the repair was carried out on a 200-meter car carrier, and in Port Burnie, Tasmania, on a 188-meter RoRo vessel.Both ships were leaking oil, making an on-site repair necessary. Using a Hydrex flexible mobdock they were able to carry out these operations on-site and underwater…

Hydrex Ready to Mobilize at Port of Rotterdam

To enable a fast mobilization throughout the entire Rotterdam port without delaying a ship’s commercials operations, Hydrex dive support vessels are stationed in Rotterdam. These workboats are fully equipped with hydraulic cranes, winches, a dive spread and control room.This allows Hydrex to offer simple maintenance operations as well as repairs on all parts of the underwater ship propulsion system and the hull.

Underwater Bow Thruster Removal in Rotterdam

Last month a Hydrex team removed a bow thruster from a 170-meter container ship. This was done during a stop in Rotterdam. The unit needed to be overhauled and the operation had to be carried out within a very short window that would fit the schedule available to the vessel’s owner.The team mobilized to the ship’s location using a workboat loaded with all the needed equipment. These workboats are fully equipped as dive support stations with hydraulic cranes…

Hydrex Earns Belgium, Netherlands Approvals

In close communication with the Dutch Ministry of Infrastructure and Water Management, Hydrex has developed a new method to clean propeller blades underwater. This method complies with the strict environmental regulations in Belgium and the Netherlands. As a result, the company has been given permission to clean propeller blades in both countries.The traditional approach in the propeller maintenance…

Underwater Bow Thruster Reinstallation

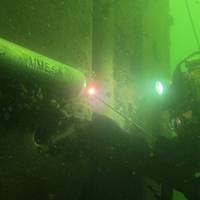

A month after a Hydrex diver/technicians removed the bow thruster of a 300-meter container vessel a team once again mobilized to Italy. They reinstalled the overhauled unit underwater with the use of the company’s flexible mobdock technique.The available time window for the removal of the bow thruster in October was very short because of the tight schedule of the vessel’s charterer. The time required to perform the operation therefore needed to be brought back to the absolute minimum.

Hydrex: Stern Tube Seal Repairs

Recently Hydrex carried out six stern tube seal operations all across Europe in a very short time span.Here is a review of two of the repairs: In Flushing the four damaged seals of a 268-meter container vessel were replaced underwater with our flexible mobdock technique. In Antwerp a seal operation was performed on a trimmed 185-meter general cargo ship. Both repairs were carried out in cooperation…

Underwater Maintenance Operations: Big and Small

Hydrex frequently performs large, complex projects across the globe, but the company says its smaller projects are equally essential. Daily, its divers conduct smaller maintenance operations including installation or replacement of anodes, blankings, replacement of transducers, propeller cleanings and all types of inspections.InspectionsBuilding upon conventional technical skills and know-how while also taking advantage of the latest technology, Hydrex offers a unique hull monitoring service.

Marine Technology: Top Five New Products @ SMM 2018

The SMM 2018 scheduled to take place September 4-7, 2018, in Hamburg, Germany, is held every two years and is the traditional launching platform for a variety of commercial shipping and shipbuilding technologies. Five new marine technologies to look for in Hamburg include:Dredging TechCompany: HydrexBooth: B7.505Product: Dredging innovationHydrex will unveil a new concept developed to protect the marine environment from the spread of contaminated sediments during dredging operations.

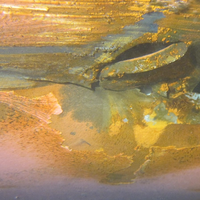

Hydrex's Doubler Plates Keep Ships Sailing

Underwater repair specialist Hydrex says when hull damage leads to the classification society to only allow temporary repair, there is a practical solution that allows ships to continue operations until a permanent repair can be scheduled. Recently called upon to inspect damage to the stern thruster area of a 195m ro-ro ship during a scheduled stop in Antwerp, the Hydrex investigation revealed a large crack in the welding seam on the edge between the hull plating and the thruster tunnel.

Hydrex to Expand Antwerp Facility

Antwerp Port Authority has supported Hydrex Underwater Technologies’ plan to expand its existing 5000m² site on Asiadok on the River Scheldt with new workshops and offices. As part of its expansion, the result of organic growth over the past two years, Hydrex has also refurbished its dive support workboats and increased its manpower by 25 percent to strengthen its diver-technician capability. Hydrex Chairman Boud Van Rompay said…

Hydrex Opens Office in Rotterdam

Hydrex has opened a new office in Rotterdam on March 1. Its purpose is to improve the delivery of services and underwater expertise to the maritime industry of Rotterdam, the company said. To enable a fast mobilization throughout the entire Rotterdam port without delaying a ship’s commercials operations, Hydrex dive support vessels will be stationed in Rotterdam. These workboats are fully equipped with hydraulic cranes, winches, a dive spread and control room.

Hydrex Cleaning and UWILD for the Offshore Market

Following is a typical case study of Hydrex in-water cleaning and UWILD services for offshore vessels and units. In this case, Hydrex carried out a full inspection and removed all fouling from three drilling vessels in the Gulf of Mexico owned by Transocean. This was done to reduce the weight and drag of the vessels and increase their available deck load. Hydrex had carried out repairs on other offshore…

Hydrex Divers Perform Underwater Repair

A Hydrex diver/technician team carried out underwater stern tube seal repairs on a 157-meter dredger in Montevideo, Uruguay in April. The ship was suffering from an oil leak, making an on-site repair necessary. Using a Hydrex flexible mobdock the team was able to carry out the entire operation on-site and underwater, saving the owner an expensive and time-consuming trip to drydock. Hydrex has carried out on-site…

Hydrex Underwater Repairs in Trinidad

Last month a Hydrex diver/technician team carried out underwater stern tube seal repairs on a 148-meter container vessel in Port of Spain, Trinidad. The ship was suffering from an oil leak, making an on-site repair necessary. Using one of the company’s flexible mobdocks the team was able to carry out the entire operation on-site and underwater, saving the owner an expensive and time-consuming trip to drydock.

Hydrex Performs Underwater Stern Tube Seal Repair

In August, the stern tube seals of a 67-meter, 2223 grt anchor handling vessel were replaced in Port Gentil by a Hydrex team of diver/technicians. The old seals were damaged and a fast repair was therefore necessary. The team carried out the entire operation on-site and underwater with one of the company’s flexible mobdocks. This saved the owner the time and money of an unscheduled trip to drydock. All Hydrex offices have fast response centers.

Hydrex Now Offer Drydock-free Permanent Propeller Repairs

Hydrex has now developed a repair system that allows them to perform permanent underwater repairs to every type of propeller in dry conditions, while still afloat. Over the years the Hydrex R&D department has continuously improved underwater repair techniques to make it possible for Hydrex diver/technicians to perform permanent repairs on seals, thrusters, rudders and almost any other part of the underwater vessel without the ship needing to go to drydock.

Hydrex Performs Underwater Propeller Blade Straightening

In April, a diver/technician team performed propeller blade straightening operations on two vessels at anchorage in Kalundborg, Denmark. First the bent blades of a 225–meter bulk carrier were restored. The team then straightened the damaged blades of 158-meter reefer in the same location. By taking advantage of the in-house developed cold straightening technique, damaged blades can be straightened underwater. This allows a ship to return to commercial operations without the need to drydock.

Hydrex Divers Repair Hulls in Europe & W. Africa

Hydrex teams of diver/technicians recently mobilized to vessels berthed in Zeebrugge (Belgium), Amsterdam (the Netherlands) and Douala (Cameroon). The teams performed insert repairs on a roro vessel and two tankers, carried out according to the Hydrex class-approved procedure for the welding of inserts in a vessel’s shell plating while afloat by using an external cofferdam. A 560 mm crack in the bottom…

- 1

- 2