Underwater Bow Thruster Reinstallation

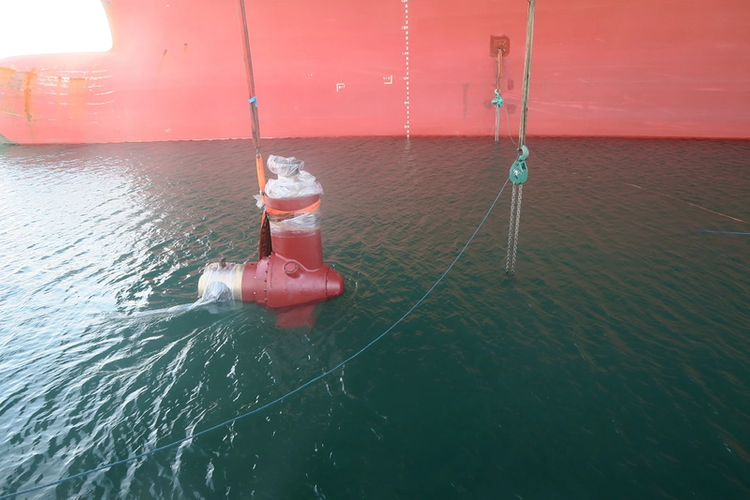

A month after a Hydrex diver/technicians removed the bow thruster of a 300-meter container vessel a team once again mobilized to Italy. They reinstalled the overhauled unit underwater with the use of the company’s flexible mobdock technique.

The available time window for the removal of the bow thruster in October was very short because of the tight schedule of the vessel’s charterer. The time required to perform the operation therefore needed to be brought back to the absolute minimum. For this reason the job was split in parts, performed in different ports. This is a good example of how Hydrex looks at the precise circumstances of each operation and find a way to tailor the operation to fit the customer’s specific needs.

The time frame for the reinstallation was slightly larger, allowing the team to carry out the job during a single stop of the vessel.

In-house technology and years of experience

Hydrex has a special R&D department continuously looking for new ways to streamline the repair procedures used by their teams. One of the results of this research are the Hydrex mobdocks. They were used to close off the thruster tunnel once the overhauled bow thruster had been brought into the tunnel. These lightweight mobdocks have been used during thruster operations for over 20 years now. They can be shipped to anywhere in the world by plane.

All water was then removed from the tunnel. This created drydock like conditions for the divers despite the vessel staying afloat. The team then secured the unit and connected it to the engine room. Once this was done the thruster propeller blades were installed one by one. With the thruster blades in position the ship was ready to sail, on schedule.

Specific solutions for specific needs

Ever since Hydrex was founded in 1974 the company has strived to keep the impact of underwater repairs for the owner as minimal as possible.

Performing operations afloat and underwater is a very important factor in doing this. Over the years Hydrex has developed techniques to perform on-site repairs to every part of the underwater ship. From damaged hulls, over leaking seals and deformed propeller blades to malfunctioning thrusters, they have a repair solution that avoids unscheduled drydock visits.

Carrying out repairs on-site alone is off course not enough. Hydrex teams can perform all operations afloat. They do this in the fastest possible time and to drydock standards. The company offer solutions to a wide range of underwater problems without sacrificing the high quality or safety standards they are known for.

Sometimes a very straightforward repair is needed. In other cases a specific, tailor-made solution is designed by the R&D department. In the case of a cruise vessel in the Caribbean the repair itself was one the teams had done on many occasions, but the ship’s time table was the tricky part. Because of the nature of the vessel, its strict schedule included many short stops. The Hydrex technical department therefore proposed a scope of work that would allow the divers to perform the replacement in stages in several different ports.

Conclusion

Hydrex can assist shipowners with almost any problem they encounter with their vessel’s thruster. A wide range of underwater repair or maintenance work can be carried out to all types of thrusters. An entire unit can be overhauled, propeller blades or seals can be replaced or repair work on a specific part of a thruster can be performed on-site.

Team members are trained to be flexible and adapt to rapidly changing circumstances. They work in shifts around the clock to finish any job as fast as possible. As a result the charterer of the container vessel in Italy did not have to worry about his vessel’s schedule.