DEX-O-TEX Light Weight Underlayment.

The challenge for ship builders has always been creating enough slope for drainage and leveled interior floors, without the sacrifice of additional weight and imbalances within the hull.

The Past

Decking Underlayments have been around for as long as ships have been sailing the seas. To prevent water pooling and increase drainage, original sailors would create slope using mud, straw and clay for the inside of their wooden hulls . Over time these methods and materials were replaced with heavier cements and plasters. The cements and plasters increased the total weight of the ship causing imbalance and structural weaknesses. Larger ships also meant more fuel expenditure and slower speeds. During the early 1900’s scientists from DEX-O-TEX Marine paired with maritime tradesmen from the commercial marine and government industry and developed a Latex Underlayment. This product was lighter compared concrete and just as strong. Latex Underlayments are still sometimes found in ships today.

Despite advances in technology and the development of latex underlayments ships were still far too heavy and slow. The challenge for ship builders has always been creating enough slope for drainage and leveled interior floors, without the sacrifice of additional weight and imbalances within the hull.

The Present

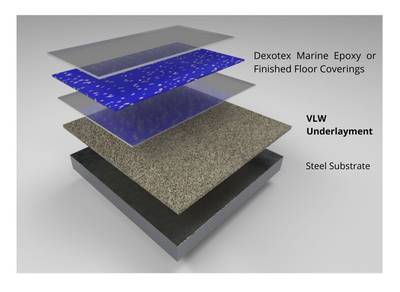

Shortly after the advent of the latex underlayments, the DEX-O-TEX Marine team was back to the drawing board. This time to develop something lighter, stronger and more durable than the previously used underlayment systems. After many trial runs and testing the team had developed a new material to replace the cements, plasters and latexes. The solution was a lightweight quartz sphere blend with specially formulated epoxy to promote flex and adhesion. The product was termed Light Weight Underlayment.

The Lightweight Underlayment ( VLW ) was launched into full production. The new underlayment is currently installed onto US Naval vessels, commercial tugboats, oil platforms, cruise ships, and recreational watercraft. MIL-SPEC , ABS and USCG IMO Approved. With the VLW Underlayment weighing less than 1 pound per sqft users have reported fuel savings upwards of 20%. Compared to concretes and latex underlayments which tend to weigh 50 pounds or more at equal applied thicknesses.

Dex-O-Marine VLW Underlayment from Dan Watt on Vimeo.

The Future

With the completion of the Light Weight Underlayment the DEX-O-TEX Marine team went on to develop additional underlayments such as the fire proof Insul-DEX, Self-leveling Elastaflake, and even a Light Weight Concrete, but when it comes to creating slope, fairing weld beads or closing spaces between welded joints VLW Underlayment is the proven solution.