The Future: Autonomous Robotic Hull Grooming

Ship hull biofouling has significant impacts on fleet readiness, ship performance, cost, and the environment. Biofouling results in increased hydrodynamic drag which results in greater fuel use and greater emissions per distance traveled than a hydraulically-smooth hull. A study by Schultz, et al. found the typical fouling rating (FR) of a US Navy DDG-51 class vessel, FR-30, increases fuel consumption by 10.3% over a hydraulically-smooth DDG-51. Results showed that reducing this fouling rating to FR-20 would lead to savings of $340K per ship and more than double that when the hull was kept at a fouling rating of FR-10, saving the US Navy nearly $800K per hull annually. And while such studies on commercial vessels are almost nonexistent, similar economic impacts of fouling are certain. A recent report cited the EMMA MAERSK, a 397m container vessel, estimated spending approximately $20K per day in propulsive fuel lost to biofouling.

The economic impact of fouling is also due to costly conventional cleaning and containment activities . A study in 2016 commissioned by the US Coast Guard, determined the cost to remove light biofouling from a ship’s hull to be $0.33 per ft2 (approximately $3.55 per m2). Based on that estimate, complete biofouling removal from a DDG-51 would run more than $10k, while the cost to remove biofouling from a Panamax class container ship would run more than $98K. These estimates are for traditional cleaning methods, which degrade the ablative coatings used for anti-fouling, leading to dry-docking for re-coating once every few years. Dry-docking a large ship may run as much as $1M-$2M.

Fouling also has significant environmental impacts, from greenhouse gas emissions associated with increased propulsive fuel costs, to the toxins released by in-water cleaning. Many countries are now requiring containment of in-water cleaning or prohibiting the practice while in port. The traditional, intense cleaning processes used to clean fouled hulls are costly, inefficient for operations, damaging to the hull coating, and environmentally unacceptable. An alternative to the reactionary intense cleaning process is the regular and thorough disruption of growth on the ship hull coating by gentle brushing with small soft-bristled brushes. This process, referred to as hull grooming, akin to brushing one’s teeth every day to avoid a monthly dentist visit and annual root canal. Research led by Dr. Geoffrey Swain at Florida Institute of Technology’s Center for Corrosion and Biofouling Control (FIT CCBC) has pioneered the methodology and practice of hull grooming, demonstrating it to be a cost-effective practice to control biofouling, while releasing far fewer toxins into the water than cleaning. Because hull grooming only lightly brushes the ship hull and does not remove coating, containment is not necessary and the life of the original coating is extended, lengthening the period between costly dry docking. Additionally, hull grooming is done with light-weight brushes making very gentle contact on the ship hull. This permits hand-held brushes that can easily be operated by divers or even brush tools that can be operated by small hull-crawling robots. The lack of need for heavy equipment to launch and recover a cleaning tool, further adds to the cost-benefit.

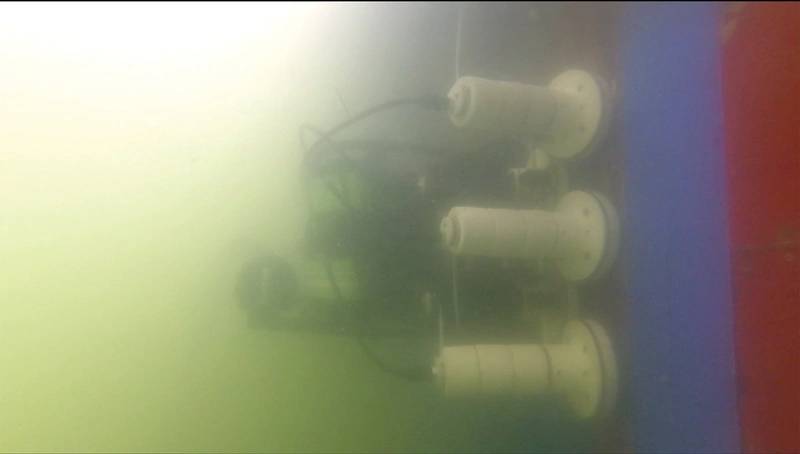

Grooming vehicle at work. Photo Courtesy Greensea Systems

Grooming vehicle at work. Photo Courtesy Greensea Systems

To be effective though, hull-grooming must be done as regularly as once a week or more and must be thorough, leaving no voids or omissions. (Continuing with the previous analogy of teeth brushing, imagine brushing all but a few teeth - a dentist visit is still in your future.) The regularity and thoroughness requirements for hull grooming present challenges to viability. For instance, a DDG-51 class ship comprises approximately 22% of the US Navy fleet by number and approximately 22% by wetted hull area. Grooming the total wetted area of this portion of the US Navy fleet once a week is logistically and financially prohibitive without a robotic means of doing so. Even with a robotic solution, the grooming time could be more than 15 hours per ship if using a single small robot and ensuring 50% overlap of grooming paths.

Several efforts over the last decade have contributed towards advancing a robotic grooming capability. These efforts have produced proven tooling, grooming methods, robotic platforms, quality assurance processes, and non-magnetic attachment methods to allow robots to crawl along a ship hull. Why then, after almost a decade of research and no fewer than 15 commercially available “hull cleaning robots”, do we still not have a solution that is really ready for adoption by the ship husbandry community? The reason is as old as robotics. Until the robot can do the job as expected with minimal operator input and until the human-robot relationship is optimal, a robot is not applicable for the job.

A robot being able to do a task relies on three primary considerations: navigation, control, and communication. Navigation: Can the robot accurately know where it is in the environment and how to get to where it is required? Control: Can the robot accurately maneuver and operate for the task? Communication: Can we meaningfully communicate our commands to the robot and interpret the status of the robot? Failure to provide completely for any of these considerations prevents an optimal robotic solution. This, we feel, is why a hull grooming robotic solution has not yet been delivered.

Greensea Systems, Inc., a software company specializing in advanced navigation, control, and autonomy solutions for marine robotics, partnered with the hull-grooming team from FIT CCBC in 2017 to explore an optimal robotic solution for hull grooming. With funding from the US Navy’s Office of Naval Research, the Greensea and CCBC FIT team fielded a prototype robotic system in 2018 that can autonomously groom a ship’s hull with very little operator input, while providing an on-hull positioning accuracy of less than 0.15m RMS. This prototype system used a commercially available ROV system fitted with a guidance and control system developed by Greensea and a grooming brush tool developed by FIT CCBC.

Accompanying the navigation solution, Greensea utilized their advanced mission planning and autonomy software modules used for Remotely Operated Vehicles (ROVs). These OPENSEA software modules provide the tools and capabilities for specifying a region to groom, planning the grooming coverage, and executing an autonomous grooming operation. The operator can supervise as a Subject Matter Expert (SME) or leave the vehicle alone to conduct the operation unassisted. The role of autonomy in the robotic grooming process is critical for the viability of this process due to the time required to ensure 100% coverage on the ship hull.

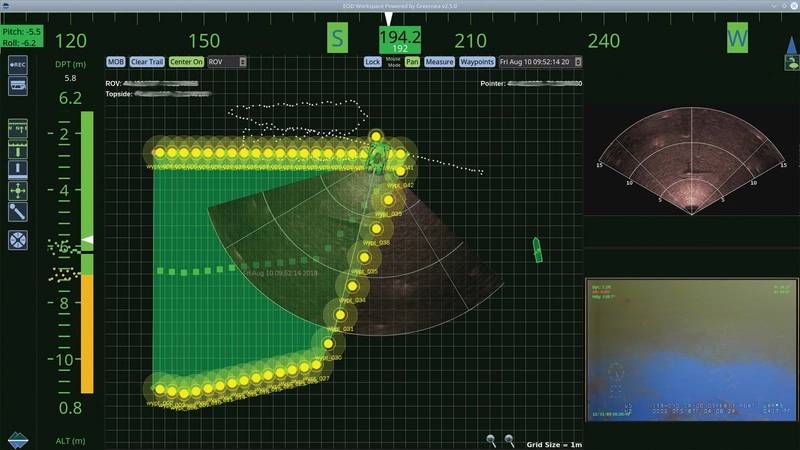

To provide the navigation and autonomy capabilities for the hull grooming robot, Greensea leveraged OPENSEA, their open architecture software platform. The autonomous hull grooming robot uses an inertial navigation system and a multibeam sonar to provide feature-based awareness of the robot’s position on the ship hull. The entire hull grooming system is implemented in a vehicle-agnostic tractor skid inclusive of the navigation and control systems, autonomy, sonar, and grooming tool. The grooming skid can easily adapt to most commercial ROVs. Greensea is commercializing the system in 2019 on a VideoRay MSS ROV.

An intuitive graphical user interface developed from Greensea’s software for Explosive Ordnance Disposal (EOD) teams provides the communication with the robot necessary for a technician to plan, execute, and document the hull grooming process. The Hull Grooming Workspace provides a view to plan the grooming operation by region, sonar overlay for obstacle avoidance, and video for complete situational awareness. Graphical indicators on the screen record the progress of the vehicle on the hull and show the grooming swath. The Workspace also allows technicians to save and recall grooming plans, log obstacles and obstructions, and log all data for archival and replay.

Greensea’s accurate hull relative navigation solution is enabling autonomous robots for hull applications and has made hull grooming a viable alternative to in water cleaning that is cost effective and environmentally responsible. Greensea is commercializing the autonomous hull grooming robot, as well as the enabling navigation and grooming technology, in 2019.

Footnote: Greensea and FIT CCBC would like to thank Office of Naval Research and DARPA for development support on the autonomous hull grooming robot as well as the feature-based navigation and localization technology used by the navigation system.

The Author

Ben Kinnaman is the founder and CEO of Greensea Systems, Inc. He has spent his career in the marine industry and created the OPENSEA open architecture software platform Greensea uses to advance marine robotics. [email protected]

Ben Kinnaman is the founder and CEO of Greensea Systems, Inc.

Ben Kinnaman is the founder and CEO of Greensea Systems, Inc.