Subsea Mining: All Eyes on Marine Minerals Offshore Norway

Marine minerals are coming under sharp focus offshore Norway. Analysts suggest it could be a $20 billion annual revenue industry by 2050, which is why many are taking an interest and developing the technology to make it happen.

Marine mineral mining has been something of a slow burner in the wider marine world. It has some clear challenges, not least location and depth of these potential resources, but also concerns around its environmental impact.

Yet it now appears to be coming into a distinctly sharp focus, not least in Norway where, early June, Norwegian Minister of Petroleum and Energy Tina Bru told a conference that “seabed minerals has the potential to become a new and important industry for Norway, the resources are present and accessible.”

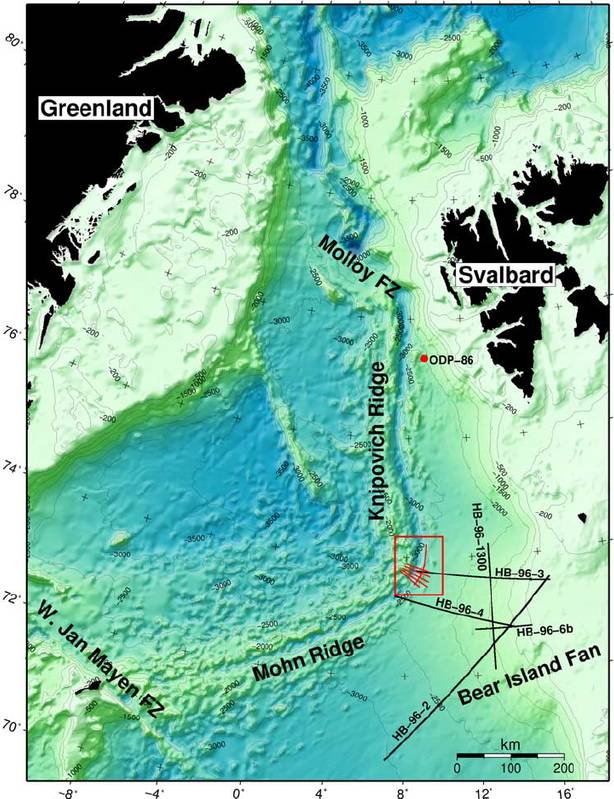

Norway is starting a process to open areas of its continental shelf for mineral activity, led by the Ministry of Petroleum and Energy. Impact and resource assessments are underway, including a research study of the Knipovich Ridge this year, before a decision on opening areas for mineral exploitation is made, Cecilie Myklatun, Chief Specialist at Norway’s Ministry of Petroleum and Energy, told the one-day, online marine minerals seminar, organised by GCE Ocean Technology and Norwegian forum for Marine Minerals (NMM).

There are a number of drivers for this enthusiasm for seabed minerals exploration and harvesting. Myklatun says that according to the International Energy Agency, current investment plans for mineral supply falls short of needs for making the likes of solar panels, wind turbines and electric vehicles. Others says there’s enough copper on land, but the grades are dropping so cost and environmental impact are increasing.

A report from November 2020 by Norwegian analysts Rystad last year pointed to the potential for a US$2 billion service industry in Norway, to support a (again) potential $20 billion annual revenue marine mineral extraction by 2050. It pointed to massive sulfides (which originate from hot vents in the ocean where sulfide-enriched water flows out of the seabed, typically in 2000-3000m water depth) as having the most potential in the country.

Not everyone is so keen. Karoline Andaur, CEO WWF Norway, points out that Volvo, Samsung, BMW and Google have called for a moratorium on deepsea mining until we know what impact it would have. “We are just beginning to discover the mysteries of the species of the deep,” she says. “We can’t risk long term and irreversible damage to these eco-systems. We need to understand the deep sea before any deep sea mining can take place.”

Fig.1. Bathymetric map of the northern part of the Norwegian-Greenland seas and the continental margins, showing the mineral Knipovich and Mohn Ridges. Image from Rolf Mjelde, University of Bergen.

Fig.1. Bathymetric map of the northern part of the Norwegian-Greenland seas and the continental margins, showing the mineral Knipovich and Mohn Ridges. Image from Rolf Mjelde, University of Bergen.

Others, like Prof. Miguel Miranda, President of IPMA, Portugal’s national ocean laboratory, told the event that we will need marine minerals, but they’re also a finite resource we should look longer term on how we can manage them so that we don’t have to keep mining. Prof Miranda also says we should be careful about what we mine first, targeting nodules first, as harvesting them is potentially less harmful to the environment.

Nevertheless, exploration for marine minerals has been going on since the 1990s, says Harald Brekke, Senior Geologist Norwegian Petroleum Directorate and Chair of the Legal and Technical Commission International Seabed Authority (ISA). Regulations for exploration of polymetallic nodules (potato-like rocks on the seabed formed of layers of iron and manganese hydroxides around a core) were adopted in 2000. However, the same for exploitation, under expected 30-year licenses, isn’t expected until 2022, at the earliest.

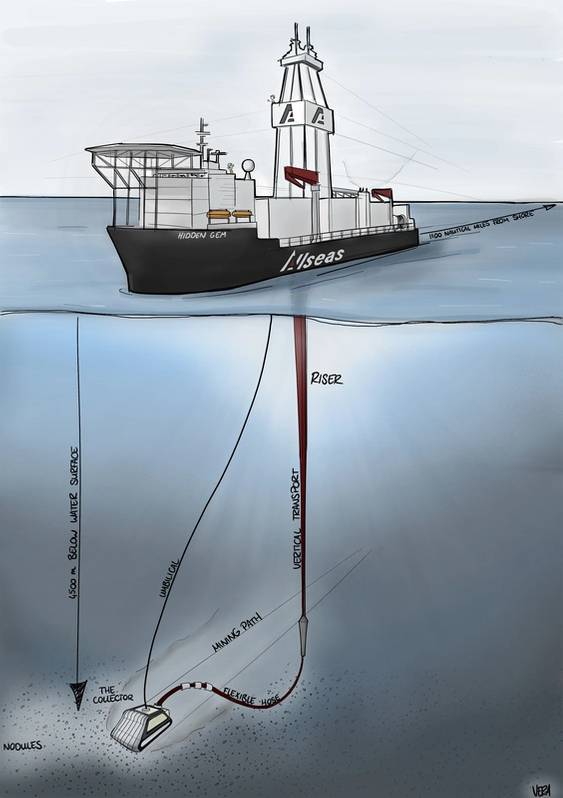

Still, companies are gearing up for this activity, creating technologies to support mineral mining. In what’s been billed as a world first, Belgium-based DEME Group’s Patania 2 nodule collector has been undergoing trials in 4,500 m water depth in the Clarion Clipperton Zone of the Pacific Ocean (where it had a minor disconnection mishap in April). Soil Machine Dynamics in Newcastle, UK, recently unveiled a new nodule collection solution, the QC2000 Nodule Collector. As well as acquiring a drillship for conversion to a nodule collection vessel (to be named Hidden Gem), Allseas is also working on a deep-sea mining harvester and riser system to gather mineral-rich nodules from the seafloor, in partnership with DeepGreen, now known as The Metals Company. New York-based Pliant Energy Systems has a more sci-fi looking robotic concept to collect nodules from the seafloor. There are many more developments out there.

During its cruise on the Mohn Ridge last year, the Norwegian Petroleum Directorate drilled for cores using riserless coiled tubing in 3,000m water depth, from the Island Valiant. Images from service provider TIOS.

During its cruise on the Mohn Ridge last year, the Norwegian Petroleum Directorate drilled for cores using riserless coiled tubing in 3,000m water depth, from the Island Valiant. Images from service provider TIOS.

But back to Norway. The Norwegian government’s interest in opening areas for mineral exploration has sparked a raft of new home-grown companies, many founded by former oil and gas or subsea industry executives. Loke Marine Minerals, for example, was founded late 2019 and is focusing on technology needs for exploration and production of seafloor massive sulfides and manganese crusts (rockhard layers on the flanks of submarine volcanoes called seamounts), both found on the Norwegian Continental Shelf, between Jan Mayan and Svalbad.

Tore Halvorsen, formerly of TechnipFMC and who now heads Technology and Operations at the firm, sees opportunity for technology and business development and says that the oil and gas and subsea heritage of Norway puts it in good stead. “There’s no off the shelf mining system for seafloor massive sulfides or manganese crusts,” he says. “The good thing is we have 50 years’ experience in oil and gas and it has a lot to offer mining.” The technology for rock cutting also exists, he says. What’s different in marine mineral mining is a new combination of environmental considerations, such as distance from shore (about 700km in fact, from the mainland), water depth at up to 3500m and winter temperatures reaching down to -27 degrees C, he says, in addition to limiting impact on the environment. “The key message is we need to spend enough time understanding the challenges, plan for it and solve it before we kick off,” he says.

“The challenge for offshore mining (massive sulfides) is continuous mining in 3.5km water depth,” he says, and getting the ore (up to 6,000 tonne of it per day) to the surface and then transferring it to shuttle tankers every seven days (amounting to some 50,000 tonnes) or perhaps wet-storing it subsea. Pumping systems, hot swappable units to maintain uptime and large-scale water treatment will be needed, in the region of 120,000 b/d, so that only clean water is discharged back to sea, he says. That all amounts to about a 30MW power requirement, which, today, would need to aim to be zero emissions, which means hydrogen or ammonia.

“None of these are show stoppers, but they have to be accommodated to have a robust system,” he says. “These sulfides are in clusters and each could be up to 300m wide and up to 250m deep. So the tool has to do horizontal and vertical cutting.” Loke has been looking at a system with dual drill cutters with an integrated suction box behind the cutter heads to allow suction of ore direct from the cutter heads to prevent plumes.”

“Manganese crust requires a different approach,” he says. They have higher porosity and low compressive strength and occur in layers on sea mounds <25cm and with relatively harder substrate. They’re often on steep and uneven surfaces, making harvesting harder for larger cutting tools, he says. “There’s been limited interest (in crusts), primarily due to lack of mining technology,” says Halvorsen. “Our approach is inspired by ROV technology, using small buoyant vehicles for cutting and collection. Several could be employed in an autonomous formation for scalability.” The company is and developing cutter heads and collection technology, as well as traction systems. “It’s very promising and we believe this technology can be a real answer.”

During its cruise on the Mohn Ridge last year, the Norwegian Petroleum Directorate drilled for cores using riserless coiled tubing in 3,000m water depth, from the Island Valiant. Images from service provider TIOS.

During its cruise on the Mohn Ridge last year, the Norwegian Petroleum Directorate drilled for cores using riserless coiled tubing in 3,000m water depth, from the Island Valiant. Images from service provider TIOS.

Some technology that has been trailed is riserless coiled tubing, for gathering cores as part of the NPD’s resource assessments. AUVs and ROVs have already been used for mapping and gathering samples, but cores provide much more information about resource potential. During the NPD’s cruise on the Mohn Ridge last year, it drilled for cores using riserless coiled tubing operated by Haliburton, in 3,000m water depth, from the Island Valiant. Bjarne Neumann, Managing Director at service provider TIOS, says the target was to get as many cores as possible in 2799-3085 m water depth.

“It was the first time coiled tubing used in this depths and on drilling sulfides,” said Sissel H. Eriksen, Senior Advisor Exploration, Norwegian Petroleum Directorate. About 40 cores were recovered during 14 runs, with a total length of 10m. It was seen as a success, but wasn’t easy. “It’s like trying to pushed cooked spaghetti in to the soil,” sys Eriksen. “It’s a real challenge.” But lessons were learned on how to do it better next time, says Neumann.

New ways to sample and core deposits is on the hit list for Bergen-based ADEPTH Minerals, which was founded last year. The firm’s CEO, Anette Tvedt, says the primary tools for resource assessment are high resolution maps and cores, but more flexible and dynamic systems are needed to get deeper cores more easily than can be done today.

It’s developing a system called Flexicore together with Seabed Solutions (co-founded the Hans Petter Klohs, who founded ADEPTH). It’s a subsea core drill unit, based on land-based drilling technology modified for deep sea operations. The first unit will be developed for operations down to 200m initially, but it will in future be able to go deeper, she says. The system is being designed to drill on challenging terrain, at 20-30 degrees, and to drill at an angle, in order to assess out crops. “Quite a bit of work has been done on the drill bits to ensure can get through these rocks,” says Tvedt. “We’re also looking at how to minimize its impact. This machine has extremely low ground pressure. Also equipment to minimise sediment plume while drilling.”

While not developed in Norway, IHC Mining has developed a vertical transport system, which has been tested in a 135m deep mine shaft and would be supported by a seawater lubricated and cooled permanent magnet motor driven pump. The latter has been tested in a fjord near Bergen at 425m water depth, but it could work at 6-9km deep with no issue, says Wiebe Boomsma, Manager Product Development, IHC Mining. “The next step is large scale pilot mining test to test the technology in full scale,” he says.

SMD’s QC2000. Image from SMD.

SMD’s QC2000. Image from SMD.

Portugal-based research institute INESC TEC (Institute for Systems and Computer Engineering, Technology and Science) has also been working on technologies for seabed mining.

This includes VAMOS, a barge-based system from which a seabed mining vehicle and a hybrid robot (the EVA AUV) are launched to perform and support mining. Eduardo Silva, Robotics Unit Coordinator, focused on a position, navigation and awareness system that the underwater systems will use to fuse real-time mapping and imaging data and support a digital twin that operations can use to guide the operation, understanding how much they’ve mined. INESC TEC has already preformed in-water trials with the system, in 15m water depth, transferring ‘mined’ material to shore via a pipeline, says Silva.

The organization is also working on underwater laser induced breakdown spectroscopy (LIBS), which could help to indicate the mineral content of material being mined. INESC TEC also has a concept called Turtle. This is a deepsea mobile robotic lander, which provides a seabed reference framework, in which the mining and hybrid vehicles can navigate, but also contains various sensors to enable a kind of rolling impact assessment as the system moves from site to site. INESC TEC also has a DNA sensor and Zooplankton imaging system it wants to add to the Turtle platform.

Silva says the next step is to move to sea trials and INESC TEC is seeking authorization to do a technical demonstration at three areas with different morphologies, water depths and current profiles offshore Portugal to test its equipment.

Deep Sea Mining Finance (DSMF), which acquired the Solwara 1 Project in Papua New Guinea, has been working on an autonomous sampler for geochemistry.

Instead of samples taken at random points in time with a towed system, this is a system that’s dropped – in multiples for aerial coverage – to the seabed to sample and later recovered. It’s about the size of a lobster trap and can collect 40 samples a day, says John Parianos, Manager Exploration, DSMF. The system, called jumping spider, has been trialed, but not deployed on a survey yet.

DSMF also has a Hobbit Scout Drilling concept, for prospect delineation. It’s a mobile seabed drilling system, deployed using standard ROV launch and recovery systems and able to land at 20 degrees, says Parianos. The firm has also just started work on downhole gamma neutron analysers which analyse backscatter from neutrons sent into a bore hole using a spectrometer. A prototype has been tested in salt water at Ciro in Australia got. Parionos says they’re looking to build a unit for testing in a well in coming months.

The Cook Islands in the Pacific are at a similar phase, says Jens Laugesen, Chief Specialist Environmental Risk Management, DNV.

The Cook Islands cover just 240 sq km of land, but their exclusive economic zone of ocean amounts to 2 million square kilometers. A study carried out over 40 years suggests there’s 12 billion tonnes of manganese nodules thought to be rich in cobalt, nickel and rare earth minerals, says Laugesen, in 5,000 m water depth over about 750,000 sq km. It has a seabed minerals authority and opened a competitive tender for seabed mineral exploration in October 2020. The winners are expected to be announced in 2H 2021.

Schematic: Allseas is also working on a deep-sea mining harvester and riser system to gather mineral-rich nodules from the seafloor, in partnership with DeepGreen, now known as The Metals Company

Schematic: Allseas is also working on a deep-sea mining harvester and riser system to gather mineral-rich nodules from the seafloor, in partnership with DeepGreen, now known as The Metals Company