The SENER engineering and technology group signed a contract last year with the U.S. based shipbuilder Fincantieri Marine Group for the license to use SENER’s FORAN System. FORAN is currently in use at one of the company’s shipyards, Fincantieri Bay Shipbuilding (FBS), located in Sturgeon Bay, Wisc.

The scope of the contract included the installation, setup, training and support for the three main FORAN disciplines: Hull Structure, Machinery & Outfitting, and Electrical Design. The training and support have enabled the FORAN users to cope with the new projects design in time and budget, so far.

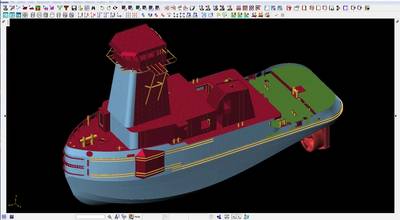

There are three units currently under development with FORAN System: two pusher tugs and one 185,000 BBL barge, all from the same ATB (Articulated Tug Barge) concept. The work currently performed in FORAN covers from basic design to production, through a very detailed 3D digital mock-up, having everything integrated within a single database.

The project is done in a real collaborative environment (remote access), with all stakeholders accessing the same data in real time. The FORAN database with all the project information is located at the shipyard facilities, in Sturgeon Bay, while the subcontractors are accessing the data remotely by using a Citrix access solution (Terminal server solution). With this approach, Guarino & Cox is developing the basic and detail design for hull, machinery and pipe from Covington, La., the shipyard is developing the electrical design, foundations and it is exploiting the 3D model for production. HVAC and Joiner are developed by subcontractors as well using their own systems and then imported in the FORAN model to allow checking of arrangements and development of effective routings.

During the design development, production personnel at the shipyard have direct access to the model and have been trained to add final production data directly. This includes plate strakes, bevel and gap data, pipe spool breaks, etc. Then production engineering at the shipyard extracts production documents directly from FORAN for steel fabrication, pipe spooling and installation, outfitting, foundations and electrical installation. This approach has lead to a further increase in collaboration between various departments within the shipyard as well as designers and subcontractors.

Another relevant aspect from the process is the development of the basic (class) design in FORAN in 3D, from which there are automatically obtained all the required class drawings. This procedure differs from the traditional set of 2D drawings approach and its room for drawings misalignment, at the same time that permits a seamless transition to the production mock-up.

After one year using FORAN in some projects, the Engineering Manager Brennan Smith expressed, “The implementation of the FORAN system at the shipyard represents a significant step in the evolution of ship design and construction in the U.S. For a couple of decades most U.S. shipyards have had functional designs developed in 2-D, often to a high level of detail, for a separate lofting operation to use in developing 3D models of hull structure and pipe with minimal outfitting. This resulted in two or more sets of design documentation that was then used to manually develop purchasing and planning documents. This was better than the old loft floor but like the loft floor this process is no longer the best available approach. FORAN allows most all of the design to be developed or added to the 3D model providing in single database of design and production information that is fully accessible by the shipyard. This shortens the time from contract to production and improves overall shipyard efficiencies.”