Pemamek Develops New Semi-narrow Groove Welding Solution

Pemamek LLC, a North American subsidiary of Finland-based Pemamek Ltd., has developed an automated semi-narrow groove welding solution with proven success in welding exceptionally thick plates ranging in size from 2 inches to 6.5 inches. Called Semi-Narrow Gap Welding, this SAW process uses significantly less consumables over the length of the operation resulting in a strong bond in less time and with fewer costs.

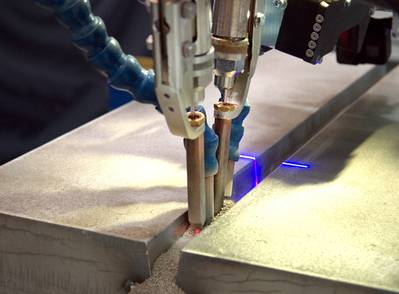

Based on submerged arc welding (SAW), the LSO process employs a welding head equipped with 5/32-inch wires. Stick-out is defined as the distance between the contact tip to the wire end. Pemamek’s tiltable welding head provides more control over the fusion process and welds bead creation for better accuracy and penetration. Full welds are possible from the root weld all the way through to the surface. For welding tubular structures, longitudinal and circular milling machines are used to mill the groove root; a 16-degree included angle is standard with an 8-degree radius on the base. The tiltable welding head helps direct the energy into the side walls of the semi-narrow groove for full penetration. Any unconsumed flux can be vacuumed, circulated and recycled.

“Pemamek’s specialized milling machines can mill both longitudinal and circular grooves. They mill the semi-narrow gap bevel immediately after the inside seam of the weld piece is welded hereby milling out the root to achieve a perfect fusion,” said Michael Bell, Director of Sales, Pemamek North America. “By starting with a workpiece milled to the ideal welding groove geometry, the volume of the weld joint is minimized while the joint itself is geometrically correct with clean groove edges, which is especially important when working with the external side of a tubular structure. Additionally, deformations and tensions are kept to a minimum because inefficient and imprecise back gouging is no longer required.”