ESAB Launches New Tracfinder Battery-Powered Welding Tractors, Cobot Welding System

To help metal fabricators improve productivity, quality and workforce needs, ESAB has launched its new Tracfinder Rail and Tracfinder Wheel series of battery-powered welding tractors and unveiled its newly branded ROBBI Mobile cobot welding system. ROBBI is now available with the Aristo Edge 500R power source and RoboFeed Edge robotic wire feeder, which offer next-generation capabilities. Compared to manual welding, these automation solutions can typically increase output per…

Dutch Shipyard Taps the Power of Robotic Welding

Next Generation Shipyards (NGS) in Lauwersoog has taken a major step toward modernizing its production line with the installation of a new state-of-the-art robotic welding system, technology that the yard says will boost efficiency, improve weld quality, and strengthen its competitive position in the specialized workboat market.The nature of shipbuilding has historically limited the usefulness of welding robots, which are typically designed for repetitive, standardized production environments.

Welding Program Helps Veterans Find a New Mission

Forged by Valor, a 501(c)(3) nonprofit in Rochester, NY, is offering an 800-hour welding education program that is operated by two veterans who understand the struggles firsthand.“Under the hood, you don’t see anything but the glow of the arc,” says Scott Quick, co-founder of Forged by Valor. A sergeant with the 75th Ranger Regiment, one of the U.S. Army’s most elite special operations units, Quick did more “crazy stuff” than he cares to remember. Fortunately, he found welding after active duty service.

Ideal Welders Contracted for Canadian Icebreaker Block Construction

Seaspan Shipyards has entered into a contract with Ideal Welders for the fabrication of 30 blocks of the new heavy Polar Icebreaker that Seaspan is building for the Canadian Coast Guard.Seaspan and Ideal Welders have had a long-standing, successful partnership — Ideal Welders has constructed many components of the ships Seaspan has built, including the bulbous bows of both Joint Support Ships, HMCS Protecteur and HMCS Preserver.Seaspan cut steel on the new Polar Icebreaker in April 2025.

ESAB's New Rogue EMP 210 PRO Compact Multiprocess Welder Hits Market

Fabrication technology specialist ESAB has announced that its new Rogue EMP 210 PRO, a compact, multiprocessor welding power source, is now in stock and available through standard distribution and online sales channels. The Rogue EMP 210 makes it easier to weld with optimized arc settings because it features an advanced digital interface and offers functions such as Synergic Control and Arc Dynamics, making it ideal for users in the light fabrication and light construction industries…

ESAB Enhances Rogue Stick and Tig Inverters with New Functionality

Fabrication technology specialist ESAB has enhanced its Rogue ES and ET line of inverters by adding DC Pulsed Stick welding functionality to all three models in the series.The models that received the upgrade include Rogue ES 151iP PRO and Rogue ES 201iP PRO Stick/Live TIG welders and the Rogue ET 201iP PRO, a TIG/Stick inverter that also offers a DC Pulsed TIG output and high-frequency (HF) TIG arc starts.All units can adjust Stick pulsing frequency between 0.2 and 100 Hz; the…

ESAB Reminder for AWS Scholarship Application Deadline

For all welding students who want to focus on education and training rather than the burden of paying for school, ESAB reminds students that the deadline to apply for AWS 2025 Foundation national, district, and section scholarships is March 1.The American Welding Society (AWS) awards more than $2.5 million in scholarships each year, including 12 scholarships in the amount of $5,000 each made possible through ESAB’s Future Fabricators program and its collaboration with the AWS Foundation.The scholarships support students working towards welding certifications…

FloCloud: Making Welding More Efficient, Cost-Effective

InduSuite introduced FloCloud, its latest application in its line of welding and cutting digital software solutions. FloCloud includes a combination pressure and flow sensor system that digitally tracks the pressure, temperature, consumption and complete flow of gas from the manifold start to the welding operator’s arc, and automatically communicates this data. FloCloud’s dashboard and reporting system tracks every end user point and sends notifications if gas pressure drops (potential leak) or if the flow is outside the process parameters and preset WPS (weld procedure specification).

MR4WELD Debuts: Mobile, Robotic Welding for Shipbuilding

Italian companies Comau and Fincantieri presented today the first result of their joint collaboration with Automatica: MR4Weld (Mobile Robot for Weld), a mobile robot, an innovative outdoor automation solution, designed to improve the quality, performance and well-being of operators during labor-intensive welding activities.The MR4Weld mobile robot is being tested and will be used in the Fincantieri shipyards to autonomously weld steel structures, with the possibility of increasing operations up to to 3 times compared to a manual process…

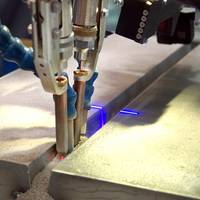

Pemamek Develops New Semi-narrow Groove Welding Solution

Pemamek LLC, a North American subsidiary of Finland-based Pemamek Ltd., has developed an automated semi-narrow groove welding solution with proven success in welding exceptionally thick plates ranging in size from 2 inches to 6.5 inches. Called Semi-Narrow Gap Welding, this SAW process uses significantly less consumables over the length of the operation resulting in a strong bond in less time and with fewer costs.Based on submerged arc welding (SAW), the LSO process employs a welding head equipped with 5/32-inch wires.

ESAB Innovation Aims to Make Shipyard Welding More Efficient, Accurate

Jeff Chittim, ESAB’s North American Senior Product Manager for Heavy Industrial Products, discusses how WeldCloud online applications and the ESAB Heavy Industrial Product Line are a powerful tandem to help shipyards improve weld quality and efficiency.While automation has gone a long way in making shipyards more efficient, today shipbuilding remains a hands-on endeavor, with a dearth of ‘welders and fitters’ being a common lament.Technology companies such as ESAB, a global supplier of welding and cutting solutions across industries…

ESAB Welding Power Sources Are Cloud-enabled

As companies around the globe seek to optimize operations through digitization, ESAB Welding & Cutting Products announced that its Aristo 4004i Pulse, Aristo 5000i and Aristo U5000i advanced welding power sources are sold exclusively as WeldCloud-enabled systems. The Aristo 500ix will continue to be sold as A WeldCloud-optional system. To encourage use, ESAB will offer Aristo purchasers a free three-month trial period, which can be activated at any time.WeldCloud is a suite of online data management applications that enables users to improve overall operational efficiency by monitoring…

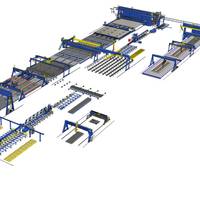

Navantia Taps Pemamek for Shipbuilding Production Lines

Navantia placed an order for the automated PEMA Panel Lines, Profile Processing Lines and Sub-Block Production Lines, designed to ensure that Navantia Shipyards will have the latest laser-hybrid-based welding and robotic technology fully integrated to create the Shipyard 4.0 working environment. The agreement between Navantia and Pemamek -- which entails several phased deliveries during the next two years -- includes an advanced automated and robotized PEMA Panel line, PEMA Profile Processing Line, and PEMA Sub-Block Production Line for Navantia’syards in Spain.

Tech File: Automated Welding Solutions

Pemamek has provided automated welding solutions to the shipbuilding industry for more than 25 years. Modular lines consisting of everything from simple robotic welding systems to entirely integrated plate preparation, joining and finishing operations can be built according to customer needs. But, according to Michael Bell, Sales Director for Pemamek LLC, the North American subsidiary of Finland-based Pemamek Oy, their systems are customizable for all types of vessels ranging from sub birthing barges…

New Norton Rapid Prep XHD Abrasive Discs

Saint-Gobain Abrasives offers new Norton Rapid Prep XHD Coarse and Medium Discs to solve users’ most aggressive stock removal and blending challenges. The extra heavy-duty non-woven discs remove weld lines, weld splatter, weld discoloration and blend surfaces in a single step.XHD Coarse is ideal for surface blending on steels, while XHD Medium works well on softer metals/ alloys. Compared with coated flap discs, users will save significant labor and consumable costs by reducing application steps.

Lowering Shipbuilding Costs with Immersive Training

The fiercely competitive domestic boatbuilding industry looks for any advantage in the day-to-day battle for bottom line efficiencies. ‘XR Technologies’ offer an edge to shipyards as they grow their workforce.In the shipyard, skills such as welding and coating are in high demand. The ability to lay down a proper bead, or perfect the mil build on a ship’s hull can make the difference between a successful project and a failed inspection. XR technologies are valuable compliments to traditional training programs (XR is an umbrella category for virtual reality [VR]…

New Product Launch: ABI-CAR Welding Tractors

ABICOR BINZEL has announced their entrance into the Hard Automation arena with the launch of their first Welding Tractor product ABI-CAR.ABI-CAR Tractors, which will initially come in three models – including one with an oscillator feature, boast a durably constructed carriage design and easy to use interface to allow welding professionals to easily operate the tractor.A strong magnet base lets the ABI-CAR be used for horizontal and vertical welding positions. The tractors come…

Water Backed Welding & Fixing FPSOs

Although MTL has a robust oil and gas heritage, with formidable experience in the global energy marketplace, it also invests heavily in R&D and undertake rigorous testing and research from its base in Kintore, Aberdeenshire. MTL recognizes the importance of progression and continual improvement for the benefit of the organisation and its staff. As a young engineer I’ve been afforded the opportunity to see new ways of working develop from the spark of a good idea through rigorous testing and finally to its successful deployment in the field.

NASA Welding Technologies Could Revolutionize Workboat Fabrication

Solid-State Welding Processes Being Developed for NASA Manufacturing Programs Could Significantly Reduce Workboat Fabrication CostsWhether it is for a tug boat, cargo vessel, or an offshore supply ship, much of the workboat fabrication industry is located along the Southern Coast of the U.S. But a visit to any one of the workboat facilities in that area (or any other in the country) would reveal antiquated and archaic fabrication processes used seventy years ago. The workboat manufacturing process is very expensive, labor intensive, and has not really changed since World War II.