Reducing costs and improving performance

Real-time reporting and data analysis are key tools to understanding and improving complex operating environments of today’s companies where the overall effects of any individual action can be very difficult to identify without a proper tool set at hand.

Identifying and continuously improving best practices are also best served by the same process which then allows shipowners and operators to see what’s happening underneath all the noise — to find what otherwise would be lost in the variance of the data.

In order to make operational improvements driven by data analysis and reporting, a systematic approach is needed that covers key areas which must be studied, analyzed, changed and constantly monitored in order to meet the desired outcome; efficient, cost-effective operations.

The five steps of this systematic approach are to:

- Identify improvement areas: digging deep into the details to find the issue

- Understand the current situation: learning how operations/processes are created and linked

- Plan improvement actions: charting a course for reaching a desired target state

- Implement change: working the plan for continuous improvement practices

- Follow up and maintain change: ensuring the change benefits continue to materialize

When analysing a fleet’s performance in general or a focused area of operations, bringing the lowest performers to at least the level of average performers is often both the fastest and most effective action.

The following examples reveal how deep analytics and reporting can pro-actively create changes that have a positive domino effect across an entire organization.

Example 1: Fleet Speed Profile Performance

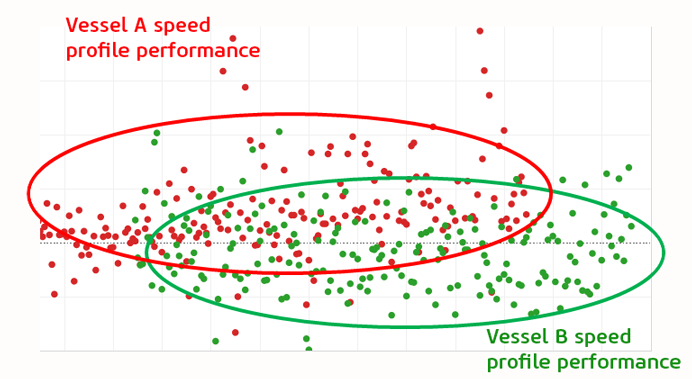

Here we have two vessels from a study we carried out with one of our customers. Each dot on the graph represents one leg that has been operated by the vessel and how much extra energy was used because of the speed profile and engine combinations. Both vessels operated on comparable schedules under similar conditions.

Problem identified: By using specific data-gathering processes via our Eniram Platform on both vessels, we were able to determine that Vessel A had a tendency to sprint in the beginning of the leg, then loiter at the end, which naturally leads to lower overall speed profile performance.

Result: By identifying the vessel differences, we were able to help the customer reduce the total fuel consumption of Vessel A by approximately 1% of the total fuel consumption. The visibility of the effects of the speed profile enabled the shipping company to take improvement actions on vessels where it was most needed.

Observation/recommendation: Further analysis can be used to find the real causes behind those differences. Planning improvement action, executing on that action and consistently following up is the only way to ensure a successful outcome.

Example 2: Bunkering Management Case Study

Our customer needed to find out if some of the vessels in their fleet were holding too much Heavy Fuel Oil (HFO) on board.

Problem identified: Again using the Eniram Platform, we performed several analyses on tank levels on these ships and found that despite consistent bunkering patterns in the same port and no major bunker price differences, many vessels were indeed holding an overage of HFO.

Result: We helped the customer eliminate the extra 1,000 tons of HFO on each vessel; the difference of over 1,000 tons of HFO onboard between the minimum levels means increased draft, and that there is an extra half a million USD tied in working capital on the vessel, which costs in total circa $100,000 each year per vessel depending on the type of vessels and company’s internal cost of capital.

Observation/recommendation: Simply by using our in-depth reporting analysis, and performing follow-ups on tank levels through a regular report that aggregates data on the amount of fuel onboard, the company could easily track fuel levels. Our customer was able to bring down the levels of HFO closer to the company’s policy; showcasing how bringing this high-level of sophisticated data analytics can help to improve overall operations when these problems become visible.

Example 3: Active Route Management

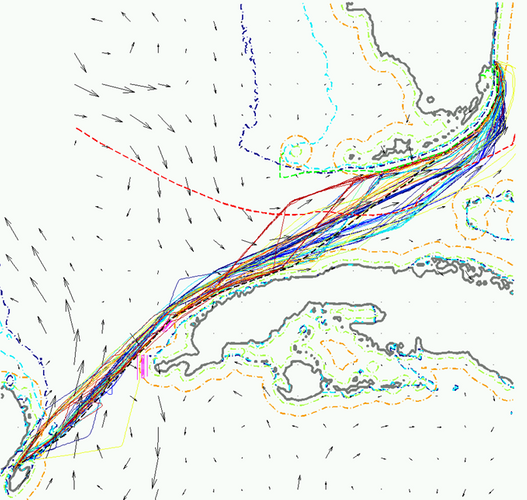

Routing is a very traditional problem and also very complex with many factors affecting it such as weather, shallows, distance to the shore, currents and ECA zones.

When analyzing routing, quite often the most effective way to improve this within the fleet is to compare where the vessels are having the most problems and then create best practices for those legs which seem to be problematic.

In this case, the difference between the best and worst routes is over 12% of the total fuel consumption (a rare case). According to our advanced analytics studies, the overall average potential improvement of actively managing routes of a fleet is typically around 3% of the total fuel consumption.

We understand that every operational issue is different and every company has different operating parameters. That’s why we customize our solution, yet use a proven systematic approach.

Our customers have come to rely on us for:

- Quick results: Data analytics and reporting is an inexpensive way to find and realize quick wins in operational efficiency. In many cases, customers see a change within a matter of weeks after we detect the problem and help them improve best practices.

- Sustainable benefits: Constant follow-up enabled by regular reporting and analytics is a key factor in maintaining the achieved benefits of all improvement actions.

- Improved understanding of operations: Detailed analysis and modeling enables separating environmental effects from operational effects and understanding where the focus of improvement action is needed.

Without data gathering, analyses and constant reporting, it can be very difficult to find the case and effect from complex onboard systems. Eniram offers our customers these tools to get at the most minute of details and unravel the mystery, bring better transparency, efficiency and operational performance to a single vessel or an entire fleet.

Henrik Lano is the director of analytics at Eniram and a former management consultant, and has broad experience from various industries in transforming data and analytics into operational insight and improvements. He is responsible for developing our analytics services to drive energy efficiency and savings for our customers. He has a M.Sc. degree in Industrial Engineering and Management from Helsinki University of Technology.