After celebrating its 50th anniversary in 2013, Van der Velden Marine Systems, a daughter company of the Damen Group, is not resting on its laurels as the Netherlands-based company’s R&D department works to continue advancing maritime maneuvering and propulsion efficiency.

“We are currently building a 97m2 Energy Saving Package (ESPAC) system for a series of three 18,000 TEU vessels being built for CMA CGM at the CSSC-affiliated Shanghai Waigaoqiao Shipyard in China,” said Edwin van Buren, Director R&D at Van der Velden Marine Systems.

ESPAC illustrates the company’s relationships with other propulsion specialists: they developed the system with German propeller manufacturer Mecklenburger Metallguss (MMG). “These are the largest rudders we have ever built and, by putting them together with 10-metre MMG propellers, the whole package will minimize fuel consumption, cavitation, vibration and maintenance.” The propulsion package combines the advantages of an optimized, highly efficient fixed pitch propeller and an asymmetric leading edge rudder with a propulsion bulb and adapted hubcaps, Van der Velden explained.

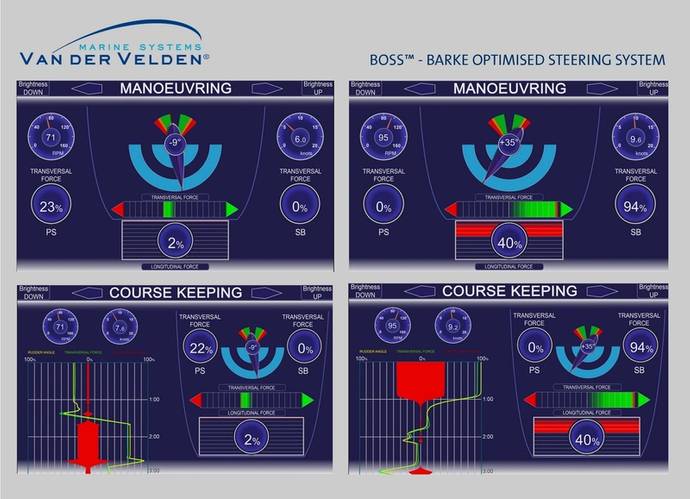

The second innovation concerns the Barke Optimized Steering System (BOSS), which provides direct feedback to the helmsman about forces acting on the rudder, serving as a tool to optimize navigation and maneuvering.

“It is important to know how much stress is placed on the rudder. The greater the resistance, the more fuel is consumed. The BOSS sensors measure these forces,” Van Buren said. The measured values are displayed on an LCD bridge display panel and are transferrable to the ship's navigation system. “Less steering corrections reduces the overshoots and shortens the distance travelled. This quickly delivers significant fuel savings.”

Van der Velden has already installed BOSS technology on two ultra-large CMA CGM-owned container vessels – the Ural and the Volga. The company recently carried commissioning and sea trials with the first BOSS system in cooperation with representatives from Damen’s own R&D team. During the IMO maneuvering and endurance tests, Van de Velden recorded BOSS data and synchronized with the vessel’s dynamics. This successful data collection represents a milestone for Van der Velden product development and creates future opportunities for the next generation of BOSS. At the same time Van der Velden’s design and engineering knowledge is developed with the ultimate benefit of clients.

The system is not limited to container vessels, however: “This technology is transferrable to the superyacht, cruise ship and dredging sectors.” The company can also pre-install measurement sensors on rudder stocks with an eye to future installation of the total system. “It’s what we call a ‘BOSS-prepared’ delivery,” Van Buren said. “This pre-installation avoids costly dry-docking in the future.”

Another recent innovation is Van der Velden’s retractable FLEX tunnel system, designed for inland and coastal ships. The system improves maneuverability, speed and overall fuel efficiency by approximately 10%. “We developed a retractable tunnel because, for about 85% of the time, loaded inland barges sail in deeper water,” Van Buren continued. “In these situations, tunnels are unnecessary. In fact, they only decrease propulsion capacity and increase fuel consumption.”

With an optimized hull design, the retractable tunnel system, developed in close collaboration with the German Development Centre for Ship Technology and Transport Systems (DST), ensures optimal water flow in both loaded and empty conditions and all water depths of inland rivers and canals.

R&D plays a crucial role across the Damen Shipyards Group. Based on its knowledge of ship design, in the 80s Damen was the first to develop arithmetical schemes and computer models to better understand propulsion characteristics – yielding more accurate predictions of strength, vibration, noise and thrust.

Damen said it built up its knowledge base through close cooperation with renowned scientific institutions such as Delft University of Technology and the University of Hamburg. Research using scale models in the testing tanks of MARIN (Maritime Research Institute Netherlands) and DST has also played a key role.

In combining the experience of maneuvering systems experts Van der Velden Marine Systems with propeller nozzle specialists Damen Marine Components, the Damen Shipyards Group is creating a center of excellence producing products such as include propeller nozzles, rudders and fuel saving systems that can be found across the entire shipping industry, on board vessels ranging from the smallest tugboats to the largest container vessels.