HydroComp NavCad, internationally recognized for resistance and propulsion prediction for naval architects, can also leverage analysis capabilities with features that support optimized hull form and propulsion system design.

NavCad may be most well-known for its library of parametric-statistical hull form and propulsion system models (often called “1D” models). The recent introduction of the Premium Edition now brings a higher-order distributed-analytical (“2D”) hull form analysis to design optimization. Called the Analytical Distributed-Volume Method (ADVM), the scope of design optimization can now offer both a first order assessment and an analytical calculation of a more refined definition of hull form.

Parametric-statistical optimization

NavCad’s parametric-statistical (“1D”) optimizing utilities specifically do not identify a singular optimum figure, but rather indicate trends and influences. As many different design requirements influence a vessel’s design and construction, employing a unique hydrodynamic optimum is rarely attainable.

Donald MacPherson, HydroComp Technical Director, notes “The Drag Reduction tool provides designers with a meaningful metric to identify changes to the present hull design that will reduce drag and increase performance and efficiency. For example, it offers practical insight into the ‘What if’ questions: What if half angle of entrance is decreased? What if I add a bulb? What if the LCG is shifted aft? Designers and naval architects now have the ability early in the design to rapidly evaluate the influence of various hull parameters on vessel drag, and more importantly, on real operational efficiency.”

The resistance curve for the initial design is the “basis” resistance. The Drag Reduction analysis then evaluates the influence on resistance of the change in various hull parameters – length, displacement, LCB, even transom immersion, for example. The hull parameters are then organized by influence, with the most significant parameter presented at the top of the table.

It is also important to consider not only the hydrodynamic influences of the parameters at the design speed, but also across the operating speed range. For example, transom immersion may be beneficial at high speed, but detrimental at lower speeds. In order to consider the influences on overall operation, NavCad’s drag reduction analysis allows the user to enter primary and secondary operating profiles using speed and time-at-speed. A “Total energy” weighted influence is calculated based on these user-defined primary and secondary operating profiles. This total energy approach allows NavCad to evaluate the effect of a hull parameter on the change of overall energy consumption of the vessel.

MacPherson continues, “By knowing the general hydrodynamic influences and trends as suggested by these tools, a designer can improve and optimize hydrodynamic performance in a way that does not compromise other design constraints, such as stability, structure, loading, or producibility. It is extremely valuable for a naval architect to simply know which direction to push a parameter when juggling the various – and often competing – design requirements.”

In a similar fashion, NavCad can evaluate the effect that vessel loading and initial trim can have on operational performance. NavCad’s Effect of initial trim utility provides useful information to designers and operators alike. In an effort to reduce fuel consumption, ship operators are often interested in the effect of initial trim on the performance of the vessel. This supplemental tool will provide an essential assessment of the effect of initial trim on bare-hull resistance for ships large and small.

Distributed-analytical optimization

The Analytical Distributed-Volume Method (ADVM) module is a bare-hull resistance prediction method that can be used to supplement a parametric-statistical method. Inspired by analytical wave-making theory, it is a prediction of ship resistance where the hull form is described by the longitudinal distribution of the immersed volume and not by parameters. Calculation of wave-making and viscous drag, including a careful prediction of form factor and frictional drag coefficients, completes the computation of total bare-hull resistance. HydroComp’s design mission for the module was to provide a method that was:

- computationally efficient,

- reliably predicted total resistance,

- was uniformly consistent and well-behaved, and

- required no extensive training in the methodology.

Due to its basis in the distribution of the immersed volume rather than its 3D wetted surface (such as is used by CFD), the definition of the hull is fully descriptive of significant shape characteristics for the purposes of optimized design. For example, where a parametric-statistical model may be limited by the nature of a parent hull form, the ADVM analysis allows any description of sectional area curve, waterplane distribution, transom immersion, entrance and run shapes.

Extensive validation studies were conducted by HydroComp for the development of the ADVM module. It is both quantitatively reliable in the prediction of resistance and qualitatively functional for comparison of design variants.

NavCad Premium includes features that allow the ADVM method to be run as a coupled solver, including a batch or macro scripting API for data and processes, and quiet mode operation without the GUI (server mode). NavCad can be coupled with third-party software such as Excel or Matlab, as well as optimizing-purposed tools like CAESES. The NavCad coupled solver process is simple and computationally very efficient.

Example optimized designs

The use of NavCad for optimized design can be for the “whole system” or a “component”. Recent published studies of “whole system” optimized design with NavCad include an AUV, waterjet-driven patrol boat, and a motor yacht. A very successful “component” optimized design study was for a bulbous bow retrofit.

System optimizations

A variety of optimized designs have been conducted using NavCad coupled with the CAESES software as the executive third-party tool for the management of the geometry and optimization processes. NavCad is the simulation solver responsible for all resistance and propulsion predictions.

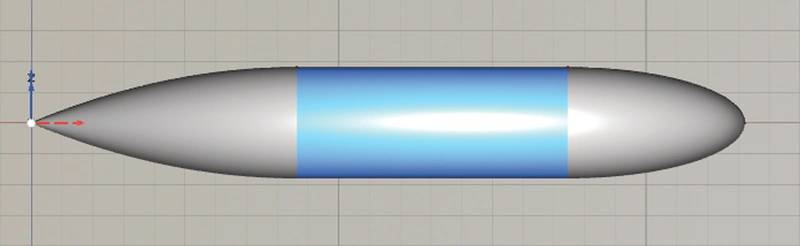

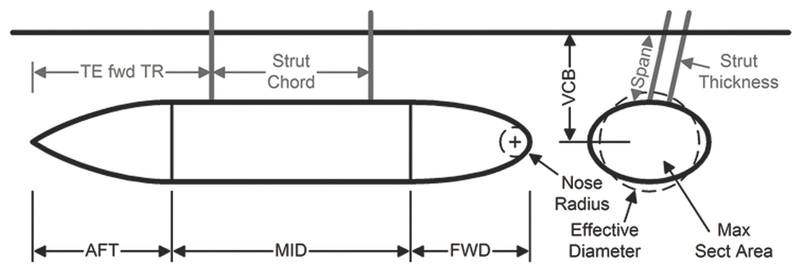

An AUV system optimization project highlighted a parametric-statistical optimization using NavCad’s Submarine/SWATH prediction methods. The hull was described as a body-of-revolution shape with three zones – fore, mid, and aft (as shown in the graphic below). The design objective was minimum shaft power, with NavCad conducting a component optimization of the propeller at each design step. An analysis of 64 variants was conducted in less than six minutes on a general-purpose business computer.

Two surface vessel projects conducted with NavCad as a coupled solver were for a waterjet-driven patrol craft and a planing motor yacht. The patrol craft used the ADVM method for resistance prediction, with an equilibrium force-moment planing solution employed for the motor yacht study. The patrol craft reviewed more than 500 variants at less than two minutes per variant, optimizing for a minimum weighted resistance-weight ratio (Telfer coefficient).

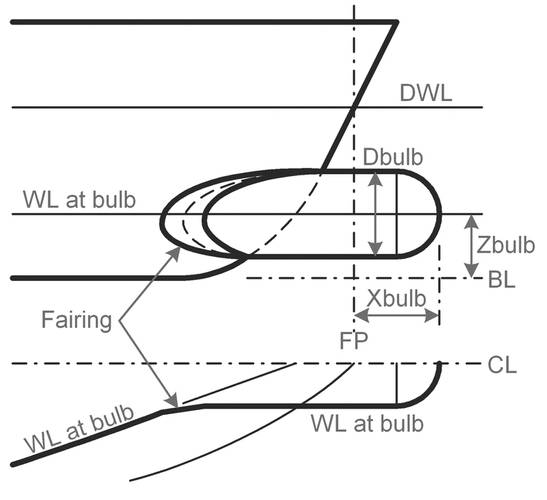

Hull form component optimization

While NavCad’s strength is in its systems engineering solutions, it is also a very powerful analysis tool for hull form component optimization. NavCad was coupled with Excel for the optimized design of a bulbous bow retrofit on a research vessel. The ADVM distributed-analytical model was used for the calculation of resistance as the volumetric shape was modified with different bulb geometries. Microsoft Excel handled the creation of the modified data and the calculation management with NavCad operating in its quiet “server mode”. A weighted total energy objective was used to determine the best combination of design parameters for the new bulb – leading to substantial reduction in fuel rate and an increase in operational top speed.