The construction of up to 20 new ferries for New York City is arguably the most exciting maritime new construction project in the U.S. this year. Last month we visited with Cameron Clark, Corporate Vice President, Development and Special Projects, Hornblower, the project manager for the new Citywide Ferry by Hornblower fleet, who discussed the challenges and opportunities ahead.

Hornblower has, in the span of 36 years, become the force in the U.S. ferry market, with more than 2,000 employees and 20 million passenger trips annually, including a cumulative staff of 700 in the New York City area. Most recently Hornblower struck a deal with the City of New York to build and manage a fleet of up to 20 new ferries serving six routes connecting the city’s five boroughs, estimated to generate 4.6 million passenger trips per annum. While the creation of Citywide Ferry by Hornblower is impressive and generating considerable buzz in U.S. maritime circles, it is the proverbial tip of the iceberg according to Clark. He views the concept as applicable to many locales with the need for water transport. “We are aiming to show not only the industry but other municipalities that Hornblower can provide a turnkey solution,” said Clark. “To design, build and finance” a fleet of ferries, a turnkey solution in rapid fashion.

The Citywide Ferry by Hornblower project is impressive for many reasons, including:

- Speed: The contract was announced in March 2016, construction on the ferries started in July 2016, and ferry operations – specifically the first three of six routes total – will start in the Summer of 2017;

- Size: The new service will include up to 20 boats serving six routes with 21 landings, covering more than 60 miles, projected to carry 4.6 million passenger trips per year.

- Collaboration: Two shipyards, Horizon Shipbuilding and Metal Shark, were jointly contracted to build the Incat Crowther designed boats. It is rare in U.S. circles for shipyards to collaborate in such a manner, sharing production and scheduling information, but as Clark explained, it was necessary to win this contract. In total more than 20 shipyards expressed interest in the project; 12 received bid packages; 10 returned bids and two were awarded newbuild contracts;

- Staffing: In step with the Hornblower way, Citywide Ferry by Hornblower is an affiliated company that started at zero and will have a staff of 150 plus … including more than 100 mariners … by the time operations start in 2017. To date Clark manages a team of about 26 at a shared workspace on Wall Street in Manhattan, a prime location with a nice view of a Hornblower terminal. “Hornblower corporate is helping from a strategic standpoint on the marketing; and (the employees of ) Citywide Ferry by Hornblower are going to wake up every day with people thinking, living and breathing Citywide Ferry,” said Clark.

Cameron Clark Takes the Helm

Cameron Clark is a graduate of the California Maritime Academy with more than 14 years of experience with Hornblower. He started with Hornblower, while in college, working part time on the San Francisco Belle. Four years ago Hornblower saw New York as an emerging market for its cruise, excursion, event and site-seeing brands, so Clark accepted the challenge and switched coasts, eventually selected to lead one of the most exciting ferry projects in the United States in a generation.

Clark is humble in approach, and he is quick to credit his team … both Hornblower corporate and direct Citywide Ferry employees … as essential to immediate and long-term success. In explaining the multiple layers that make up Hornblower, he said “These are a series of companies and business units that operate independently, with common ownership. We come together when we need to work together. For example at Citywide Ferry, HMS Consulting is helping us in a program management capacity with the shipyards. HMS Ferries is supporting the transition of East River Ferry.”

Similarly, Clark is open to looking outside of the maritime box when selecting the best talent for the project, noting that the new company’s ‘head of customer success’ came from JetBlue.

“Passengers – no matter where the ferry is going – have expectations,” said Clark. Getting passengers from ‘point A to point B’ safely and on time is the base expectation; performing safe and reliable transportation with clean boats and a friendly attitude is the Hornblower way. “We can be safe, reliable, on time in a hospitable manner; and, oh, the ride is only $2.75 (on the new ferry service). This is the attitude and approach that we apply to any of our businesses across the country.”

Building the Boats

With a budget of $80 million for the boats and a mandate to deliver up to 20 ferries in less than two years, from the outset the project required an innovative mindset. Perhaps nothing better embodies this than the decision to employ two shipyards to construct the new fleet.

The tight timeline to deliver ferry service to the five boroughs of New York was the primary driver for the selection of two shipyards to fulfill the contract. The contract was announced in March 2016, vessel construction commencing in July 2016, and first ferry service scheduled to begin in the summer of 2017.

“No single shipyard would agree to build 19 boats in such a short timeframe, so we decided to break it up to be in more than one shipyard,” said Sarah McDonald, Special Projects Coordinator- Citywide Ferry Service, “but we also wanted to minimize the total number of shipyards, because the objective is to have 19 exact vessels across the fleet.”

This type of collaboration is far from common, particularly in the U.S. boatbuilding market where production and scheduling details are trade secrets of the first order, so according to McDonald, “the biggest challenge is the communication across the two yards, as yards traditionally don’t work together. But these two yards (Horizon Shipbuilding of Bayou La Batre, AL and Metal Shark of Franklin, La.) decided to work together, using the Gordhead software program.”

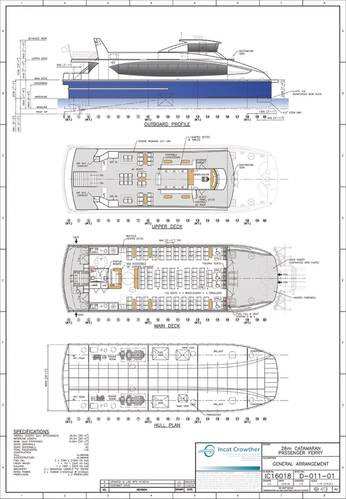

The two yards are building identical Incat Crowther designed, 26-meter, 149-passenger aluminum high-speed ferries, though it was not announced exactly how many boats each yard will build. By late autumn 2016 both yards were busy building the hulls totally under cover and expanding local workspaces to make sure that remained the case. Horizon, which has expanded its facilities and production capabilities in recent years, will build the ferries using an assembly-line type roll-out with the first boat ready for delivery in the first quarter of 2017. Metal Shark’s newbuild program is also full steam ahead. In advance of the contract award, Metal Shark won a MARAD grant and will complete a 150 x 80-ft. auxiliary structure for final assembly, which was partially funded by the MARAD grant. A new 160-ton Marine Lift transporter arrives in January and will significantly facilitate the movement of boats around the yard and to the water for launch.

While the arrangement is unique he contends that it has proven beneficial to the yards themselves in some regards, as the strong cooperation and communication has helped the shipyards to reduce the design and production costs, as they learn each other’s capabilities and strengths, and divvy out the assignment responsibilities so there is not a duplication of effort. “I think it goes to show that you can be open and transparent, and still be competitive,” said Cameron. “I credit the shipyards and their attitude. Part of our decision on these two shipyards was seeing their willingness to break down that traditional barrier and work together, with Incat helping to mediate. We want to know that these ships will be exactly alike. I think we will be able to accomplish that due to this collaborative effort.”

The Project

A project of this magnitude, particularly one involving a major municipality, is sure to generate much attention, and Citywide Ferry by Hornblower has been planning to ensure the boats and operations are delivered above expectation. In particular, energy efficiency and the environment has been a mantra from the outset.

“Energy reduction on the vessel overall was important, so we have LED lighting throughout, for example,” said Clark. “(Another example can be seen) in the materials that we use; we are wrapping the vessels with vinyl as opposed to painting them, to help reduce VOCs as well as to minimize sanding in the future.”

Clark said that the efficiency focus started in the initial design phase, and “A lot of energy was put into hull form. We wanted a vessel with the best wake/wash performance of any hull in New York harbor,” helping on everything from fuel consumption to the reduction of shoreline erosion.

In selecting the power to propel the vessels, Clark and his team opted for Tier III diesel engines from Baudouin. While ‘all-electric’ and ‘LNG-powered’ ferries are evolving from a novelty, gaining favor yet still a far cry from mainstream, Clark contends that the Tier III diesel option proved to be the prudent choice on a project of this magnitude and timescale. “When you’re doing something rapidly, you want to minimize risks. The best way to do that is a common platform. The route and power and speed requirements for the East River service are different from the Rockaway service. But we didn’t want something that precluded us from being nimble and evolving the system.”

The challenges to this project are not relegated to the vessels alone.

“What is most different for me (for this project) is having 22 ‘front doors,’” said Annabella Stagner, Vice President of Sales & Marketing, Hornblower. “Every boarding location is a ‘front door’ versus, for example our Statue of Liberty route where Battery Park and Statue of Liberty are the only two ‘front doors.’ This gives us an opportunity for access to communities unlike we have ever had before.”

“The way that it is the same? We are creating a platform for amazing experiences that go beyond transportation services. Something that Hornblower tries to bring to every start up, with every journey, is to ensure that the passenger comes away with the feeling that they have been cared for,” said Stagner.

While Clark acknowledges the challenges, he neatly summarizes how his company is able to fulfill efficiently.

“There are a lot of moving pieces; I think we’re trying to develop something that’s going to meet the needs of millions of people, and the needs in one community are different than the needs of another community. I think the biggest challenge is pulling it all together. That said, and I know I’m biased, but I can’t think of another operator in the country that would be able to finance, design, project manage, build, develop app technology, market to millions of people, hire a team of operational people and guest services people, work through city politics, and do it all in 18 months.”

The Routes & The Boats

Starting Summer 2017, Citywide Ferry by Hornblower will provide a new affordable way to travel between waterfront communities throughout New York City. When Citywide Ferry by Hornblower becomes fully operational in 2018, the six routes will carry an estimated 4.6 million passenger trips per year.

- Combined, the routes will cover over 60 miles of waterway

- More than half a million New Yorkers live within a half-mile of one of the 21 Citywide Ferry landings

Rockaway Route

The Rockaway Route of the Citywide Ferry will provide a key transit link between the Rockaways, Sunset Park, and Lower Manhattan, while connecting New Yorkers to our city’s beaches.

Astoria Route

The Astoria Route of the Citywide Ferry will connect the growing residential and business communities of Western Queens; Roosevelt Island, including the new Cornell Tech campus; and residents and job centers in Midtown and the Financial District.

South Brooklyn Route

The South Brooklyn Route of the Citywide Ferry will connect South Brooklyn’s residential communities, waterfront parks, and innovative industries to residents and job centers in Midtown and the Financial District.

North Brooklyn Route

The North Brooklyn Route (Formerly known as East River Ferry) features frequent, reliable service that connects Manhattan with various destinations in Brooklyn, Queens and seasonally on Governor’s Island.

Lower East Side Route

The Lower East Side Route of the Citywide Ferry will connect residents with job centers in Midtown, the Financial District, and Long Island City.

Soundview Route

The Soundview Route of the Citywide Ferry will connect communities in the Bronx and the Upper East Side with job centers in Lower Manhattan.

Main Particulars: Citywide Ferry by Hornblower

Owner Hornblower

Shipbuilders Horizon Shipbuilding & Metal Shark

Designer Incat Crowther

Software Gordhead software (used by Horizon)

Material Marine grade aluminum

Hull form Round chine catamaran

Length o.a. 85.4 ft. (26 m)

Length Hull 80.5 ft. (24.5 m)

Length on design w.l. 80.5 ft. (24.5 m)

Beam (not including sponsons) 26.3 ft. (8 m)

Draft (hull only – approx.) 3.4 ft. (1 )

Draft (max – prop tip) 6.1 ft. (1.85 m)

Depth of hull 8.8 ft. (2.7 m)

Freeboard (stern) 5.5 ft. (1.68 m)

Freeboard (bow) 5.5 ft. (1.68 m)

Estimated Weight:

Aluminum Structure 50,706 lbs (23,000 kg)

Lightship 103,617lbs (47,000 kg)

Tank Capacities:

Fuel (Ships Tank) 2 x 750 gal. (2 x 2,840 l)

Fresh water 1 x 200 gal. (1 x 757 l)

Black / Grey Water 1 x 500 gal. (1 x 1,900 l)

Flag State: United States

Survey: USCG

Main Engines (River Design) 2 x Baudouin

6M26.3 ‘P3 Rated’

Output 815mph @ 2100rpm

Main Engines (Rockaway Design) 2 x Baudouin 12M26.3 ‘P2 Rated’

Output 1400 mph @ 2100 rpm

Gearbox ZF2050

Ratio 2.519:1

Operating Speed 25 knots, max deadweight, 90% MCR

Fuel Consumption Main 34.5 gal./hr. at 90% MCR

Fuel Consumption Gens 4 gal./hr. (nominal)

Range 400 nm at 90% MCR at Max

Deadweight with 10% reserve

Propellers (River Design) 2 x Michigan Wheel,

5 Blades, 38-in. diameter

Propellers (Rockaway Design) 2 x Michigan Wheel,

5 Blades, 42-in. diameter

Generator John Deere Model 4045T

Struts Michigan Wheel – single strut casting

Fuel Service System Murphy EL150 Level Switches

Racor 500MA fuel filter

LK quick closing valves

TM Aluminum Electronic Flow Meter

Keel Coolers Fernstrum Grid Coolers

M.E. Exhaust System Delta-T / Dinak GE50+

Generator Exhaust Delta T / Dinak GE50+ DN80/180

Batteries 24 V Odyssey PC1800-FT

Automatic Battery Charger Newmar PTMS-24-67

Power Outlets Leviton T5632 USB

Main Switchboard Power Panels LLC

Lighting Low Voltage LED Lights

Navigation Lights Perko 1379001BLK

Searchlight Golight 2020

Radar, Fish Finder, GPS, AIS Furuno System

Acoustical Kahlenberg KB-30 horn

Audio System RANE

Captain’s Mic Shure 514B

Media Player Brightsign HD1022

Headphone Jacks RDL D-HA1A

Radio Systems Icom IC-M424G VHF radios

Fire Detection System Sea-Fire FireStop

Ventilation System Delta T

Air Conditioning System Daikin Mini-Split A/C Units

Bilge Pump Goulds Model LSP0711F

Deck Heating Integral underdeck

box tubing circulating system

Mach 5 M5-115 Pumps

Rheem RTE tankless electric water heaters

Steering System Jastram electro-hydraulic

Interceptor Humphree HE950 interceptors

Anchor Fortress FX-125 69lb anchor

Seating Freedman Gemini Series

Signage Daktronics

Restrooms, Toilet ACORN 2120-T-3-ULF-FVL-ADA

Restrooms, Flush Valve TOTO TET1LA EcoPower

Restrooms, Urinal ACORN 2159

Restrooms, Hands free lavatory ACORN 1953-L

Restrooms, Hand dryer Dyson Airblade V

Restrooms, Doors Libra

Restrooms, Hatches Freeman

Notation Subchapter T Service restriction

Rivers (cold water) Partially Protected Waters

Tonnage: Less than 100 regulatory tons

The New Ferry Landings

Dimensions 90 x 35 ft.

Designer McLaren Engineering Group

All landings are ADA and LL68 compliant

10 new landings are built and open in 2017

Landings have low profiles to preserve views

Barges for the ferry landing are made on Staten Island

Landings are equipped with canopies and wind screens and radiant heaters to shelter from seasonal weather conditions