Hapag-Lloyd Scratches Fouling ITCH with Shipshave’s Solution

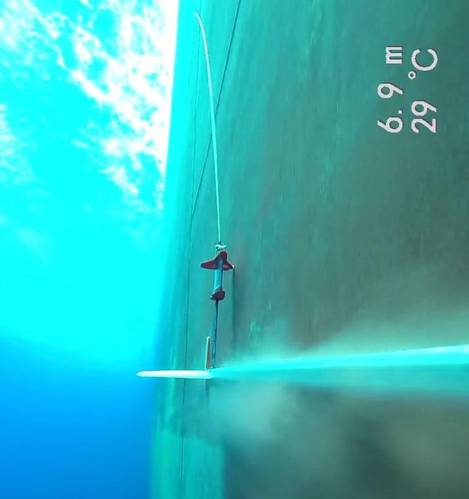

German container line operator Hapag-Lloyd has implemented Shipshave’s In Transit Cleaning of Hull (ITCH) solution for proactive fouling removal on two of its container ships, achieving significant fuel savings and emissions reduction results.

In order to independently verify the benefit of proactive fouling removal, Shipshave in cooperation with Hapag-Lloyd commissioned DNV to analyse operational performance data from two Hapag-Lloyd container ships equipped with the ITCH solution.

The vessels are of 8,749-TEU and 18,800-TEU, respectively, of different ages and with different trading profiles.

The analysis included data harvested from both vessels over a 17-month period, allowing for an in-depth consideration of 'trend over time' to examine whether Hapag-Lloyd's proactive approach to hull cleaning delivered a representative and consistent result.

In its report following the assessment, DNV confirms that both ships achieved a significant fuel saving and reduction in emissions based on improved energy efficiency.

According to the DNV study, the actual reduction in fuel and emissions varied between them due to their different dimensions and operating profile, but both were impressive.

One saw a 16% improvement in performance equal to a reduction in fuel consumption of approximately 8.4 tons per day – which equates to removing the emissions of over 4,900 fossil-fuel-driven cars over the same time period.

The other vessel showed better initial performance but still achieved a reduction in fuel consumption of just under 5%. The performance was maintained over time by regularly using the ITCH unit.

Over the assessment period, the ITCH system successfully managed hull biofouling, by initially reducing resistance. Additional fouling would accumulate over time without repeated hull cleaning.

Proactive grooming prevents future degradation of vessel performance due to fouling re-growth. This long-term effect was not accounted for in the analysis and is likely to underestimate the total economic benefit of proactive cleaning with ITCH.

Nevertheless, Return on Investment (ROI) from the ITCH system for the two vessels was under three months at sea in these cases, according to the report.

“We are very pleased that this analysis from DNV confirms our internal assessment of the result achieved by the implementation of ITCH. This method reflects our proactive approach to reducing emissions caused by biofouling,” said Nikhilesh Bhatia, Director Fleet Energy Efficiency, being responsible for the ITCH project at Hapag-Lloyd.

“The findings of this case study emphasize the critical role of minimizing biofouling in reducing greenhouse gas emissions from shipping. As outlined in our recent Maritime Forecast to 2050 report, regular or proactive hull cleaning remains one of the most effective strategies to achieve this goal," added Uwe Hollenbach, Senior Principal Consultant at DNV Maritime Advisory, Ship Performance Center, Hamburg.