ABB Azipod Efficiency Improved Again

Continuous effort to improve Azipod energy efficiency.

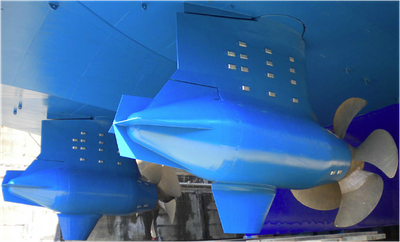

ABB, a power and automation technology group, has announced that recent modifications to its Azipod propulsion unit fr ame design have seen hydrodynamic efficiency improved by more than two percent. The modifications include a newly optimized Azipod fin shape and a new pod cap structure, called Xtail. The revised fin structure receives water flow from the propeller at a new, less acute angle, and its new curved design redirects the flow more efficiently. The unit’s new X-tail, installed for the pod cap structure, straightens water flow on ejection from the Azipod propulsor, minimizing water swirling.

Royal Caribbean International’s Radiance of the Seas was the first cruise ships to benefit from the new fin shape and X-tail. The modifications to Azipod were completed during her drydock in May 2011. Her sailings from May to September witnessed the benefits when compared to a sister vessel and her previous operational portfolio: more than 2 percent in hydrodynamic efficiency improvement was achieved.

Based on the positive result from the test, ABB will now include its new features in new Azipod XO units and provide refitted services to existing vessels equipped with older Azipod VO and XO units. At the beginning of this year ABB together with Eniram introduced Azipod Dynamic Optimizer (ADO), a software tool which optimizes the Azipod toe angle. The tool has further improved unit efficiency and initial results from the trial installation on Holland America Line’s Noordam indicate that 1.5 percent savings may be achievable on this vessel.

“Azipod propulsion has been in the market about 20 years and a lot of hydrodynamic improvements have been made during that time. However, from the hydrodynamic point of view the system still has a lot of potential. More new ideas will be studied, tested and applied to improve ship fuel efficiency” said Tomi Veikonheimo, chief hydrodynamist at ABB Marine. When the Azipod propulsion system was first introduced to the cruise market in 1990s, around an

eight per cent rise in efficiency was recorded compared to existing ships, in terms of shaft line efficiency. After that, step by step improvements were made to the Azipod shape, resulting in about another seven percent efficiency improvement. Two years ago, when ‘next generation’ Azipod - Azipod XO units were launched, another two per cent improvement was achieved. Thus combining this to the recent improvements, Azipod hydrodynamic efficiency has totally been improved by more than 12 percent compared to the first cruise vessel application.

“The fuel efficiency improvements measured on Radiance of the Seas are welcomed reprieve in today’s higher fuel prices” said Anders Aasen, Associate Vice President of Technical Services for Royal Caribbean International and Azamara Cruises. “Any improvements we can make on fuel efficiency will serve us well for future operational costs.”

“Azipod is one of ABB’s most recognized products, denoting the company’s energy efficient solutions for marine applications and offering up to 20 percent in energy savings. However, the pursuit of better efficiency, maneuverability, safety and crew comfort has never ceased,” says Heikki Soljama, Global Head of ABB’s Business Unit Marine and Cranes. To date, over 100 vessels have been equipped with Azipod propulsion units and more than 240 Azipod units have been delivered or are on order, accumulating about seven million reliable operating hours in demanding marine applications such as icebreakers, luxury cruise ships, research vessels, offshore supply vessels, drilling rigs, ferries and mega yachts.