CTVs: Future-proofing Today’s Offshore Wind Solutions

The first commercial application of Volvo Penta’s IPS Professional Platform will power Northern Offshore Services’ next-gen crew transfer vessel. Longtime collaborators Volvo Penta and N-O-S aim to more than satisfy the unique requirements of a possible 25x increase in offshore wind production.

Upon arrival in Gothenburg, an observant visitor quickly realizes that Sweden is one of the cleanest places on earth. Epitomizing that lofty standard are two marine industry heavyweights, both domiciled here, and – not coincidentally – both collaborating with one another for two decades to create some of the safest and ecologically correct equipment on the planet. As Volvo Penta and Northern Offshore Services (N-O-S) move forward, how and why that happens are both equally important.

In late August, N-O-S unveiled the new I-Class crew transfer vessel (CTV), powered by the first real-world commercial application of Volvo Penta’s IPS Professional Platform. The cutting-edge Impresser is already operating in a U.K. wind farm. Nevertheless, the launch of the Impresser isn’t the end of the story. Nor is it the beginning. Instead, it heralds a new era for a marine sector that is anything but mature, and which finds itself in an era of market flux, political and regulatory uncertainties, and the undeniable need for standardized, environmentally sound partnerships and performance.

The well attended christening of the CTV IMPRESSER, the latest N-O-S addition to its impressive 67 vessel fleet. The ceremony was a joyful event, well attended by a wide spectrum of industry stakeholders. On the dais were the many children of N-O-S executives David Kristensson and Martin Landstrom. Following the playing of both the Swedish and Danish national anthems, the magic moment took place to thunderous applause from the gathered masses. (Credit: Joseph Keefe)

The well attended christening of the CTV IMPRESSER, the latest N-O-S addition to its impressive 67 vessel fleet. The ceremony was a joyful event, well attended by a wide spectrum of industry stakeholders. On the dais were the many children of N-O-S executives David Kristensson and Martin Landstrom. Following the playing of both the Swedish and Danish national anthems, the magic moment took place to thunderous applause from the gathered masses. (Credit: Joseph Keefe)

For its part, N-O-S designed a flexible, future-proof CTV that will adapt to and accommodate new technologies and energy solutions while it is in service over the next 25 years. Near the very heart of that effort is Volvo Penta’s integrated IPS Professional Platform.

“Northern Offshore Services and Volvo Penta share an innovative spirit that drives us both. [Today] that resulted in the first vessel powered by Volvo Penta’s IPS Professional Platform entering real-world commercial operations,” said Johan Inden, president of Volvo Penta Marine. “N-O-S’ deep experience in building vessels for some of the most demanding environments challenged us to develop new ways to improve our propulsion systems and adapt to emerging technologies.”

“The offshore wind industry is relatively young and has grown tremendously during the last 15 years. Since we began N-O-S in 2008, we have seen wind turbines become significantly larger, which results in more maintenance, increased downtime and more technicians at sea,” said David Kristensson, group CEO and owner of Northern Offshore Group. “These are just some of the challenges that are catalyzing innovation and driving the design and manufacture of our vessels in house to meet the customer demands of tomorrow.”

Meet Volvo Penta & N-O-S:

Volvo Penta is a global supplier of power solutions, at sea and ashore, leveraging 100 years of marine expertise in its drive towards sustainability. Part of the Volvo Group, the firm boasts a global network of 3,500 service dealers, delivering more than 44,000 engines, with 21 billion SEK (US$2 billion) in annual turnover, spanning 130 countries. While the iconic Volvo car business is no longer under the same umbrella, the firm notably owns Mack truck. Volvo Penta revenues in 2023 were split evenly between marine and shoreside applications; arguably unusual for a marine supplier where the split is often a much smaller slice of the pie for the marine side, especially when it comes to engine OEMs. An impressive 8% of total revenues are spent on R&D, while Volvo Penta’s sustainability goals are to reduce its carbon footprint by 50% by 2030.

Separately, Northern Offshore Services (N-O-S) is a much younger firm, but quickly has become one of the world’s most recognizable providers of CTVs. N-O-S operates 67 vessels, mostly in the CTV markets, but also has penetration in the smaller tanker and supply vessel sectors. With offices located in Gothenburg, Sweden; Copenhagen, Denmark; and Conwy, U.K.; N-O-S today is headquartered Donsö, an island in Gothenburg’s southern archipelago, in Sweden.

A specialist company operating around the world in over 90 wind farms, N-O-S and its vessels completed 118,000 successful cargo and/or personnel transfers in 2023 alone. Along the way, they found the time and capex to fund 24 newbuild deliveries during the same short period. That would be heady stuff for most companies, but as Kristensson, often says, a forwarding-thinking firm “should not just sit on its hands, rather, it should stand on its toes.”

N-O-S’ new CTV Impresser (Credit: N-O-S)

N-O-S’ new CTV Impresser (Credit: N-O-S)

The majority of N-O-S business takes place in the U.K. and Denmark offshore arena. The firm nevertheless has its eyes on the bigger prize, as the wind farm market, always a wild card for investors trying to figure out which way the proverbial winds are blowing, slowly expands across the world. Despite the uncertainties that swirl in the American markets, N-O-S has plunged ahead there, as well. Through their Providence, R.I.-based fledgling joint venture subsidiary group, American Offshore Services (A-O-S), N-O-S should have four vessels in operation by the end of the year, with a five-year goal of 6-10 more to be added to the fleet. As N-O-S plows ahead with the maritime metaphorical ‘bone in its teeth,’ Kristensson says with confidence, “It is not the big that will be beat the small; it is the fast that will beat the slow.”

“A forwarding thinking firm should not just sit on its hands, rather, it should stand on its toes.” - N-O-S CEO David Kristensson (Credit: N-O-S)

“A forwarding thinking firm should not just sit on its hands, rather, it should stand on its toes.” - N-O-S CEO David Kristensson (Credit: N-O-S)

But, N-O-S has no intention of expanding only in terms of numerical boat numbers. Its innovative leaders are more importantly focused on converting the additional fleet to comply with and operate greener tonnage that not only anticipates, but both satisfies and exceeds regulatory requirements, with an eye on electric and hybrid solutions. This is where their close collaboration with Volvo Penta is so important.

Volvo Penta and the IPS Professional Platform

Inden cuts straight to the heart of the matter when he says, “Today’s markets bring better day rates for greener vessels.” Unspoken in that simple message is the reality that there is little point in being the greenest operator on the high sea if you can’t turn a profit. And, if you are going to build a cutting-edge vessel that includes the newest in propulsion technologies—something that might increase the cost of that newbuild by as much as 20%—then the customer will need proof that the effort is worth the journey. For Volvo Penta, that’s no problem at all.

“Today’s markets bring better day rates for greener vessels.” - Johan Inden, President of Volvo Penta Marine (Photo: Volvo Penta)

“Today’s markets bring better day rates for greener vessels.” - Johan Inden, President of Volvo Penta Marine (Photo: Volvo Penta)

When it comes to the Volvo Penta IPS Propulsion Platform, the leisure markets were first, followed now by the commercial marine operators. The initial success of the IPS platform in the leisure markets didn’t happen in a vacuum. It all starts at Krossholman, Volvo Penta’s unique test and proving marine center.

In operation since 1967, the facility today boasts 30 test boats, 28 employees and a maintenance crew that supports testing and R&D. Here, any particular hull and related propulsion solution may see as many as 9,000 testing hours. Volvo Penta regularly sponsors customer clinics where the potential buyer shares what they are planning. Volvo Penta then reciprocates and creates a propulsion solution to match.

As Volvo Penta prepared to introduce the successful IPS platform to the commercial markets, Inden knew that future customers would need solid, verifiable and repeatable data with which make decisions. In response, the M/V Penta 40, a 37-meter catamaran, was purchased. The test vessel boasted a fairly new propulsion solution (controllable pitch props), installed by a Volvo Penta competitor. In other words, the perfect vessel to benchmark the performance of the existing propulsion system, before it was refitted with the IPS solution. And, the differences—marked performance improvements—were clear from the start.

(Credit: Volvo Penta)

(Credit: Volvo Penta)

| Volvo Penta 40 Repower Data: | |

|---|---|

| Power: | Reduced time to full speed from ~60 seconds down to <30 seconds. |

| Fuel Economy: | Tier 3 Performance with SCR after-treatment. Engines approved to run Hydrotreated Vegetable Oil (HVO) and can reduce emissions by up to 90 percent. I-Class vessel engines could potentially see up to 30 percent total fuel savings. |

| Comfort: | 50% less noise and vibration. |

| Safety: | Joystick operation makes docking & maneuvering far easier. 40-degree steering obviates need for thrusters. |

| Internal Space Savings: | 4 meters of extra space on each catamaran. Full IPS solution involves a considerably lower propulsion profile. |

| Engine kW: | Reduced to 2,360 from 2,900 (less power / same top speed). |

| Turning Circle: | Tighter by 20%. |

| Weight: | Repowered IPS vessel is 2 tonnes lighter. |

| Operational / Maintenance: | 1,400 hours on both engines versus 2,000 on previous single engine. More time in between overhauls, less off-hire time, less wear-and-tear on the propulsion package. |

First introduced in 2005, IPS has evolved from the IPS 10, 20, 30 and now, the 40. Not only did it grow in size; it grew in functionality. Easier and more intuitive, user-friendly controls translate into reduced stress on the crew and captain, which in turn, says Volvo Penta, translates into increased safety.

As Volvo Penta scaled up to the IPS Professional Platform, a key aspect of their marketing push is that the client only has to deal with one vendor—“helm-to-prop”, the company says. Beyond that, maintenance might involve pod removal, but that’s much easier than pulling a shaft. That’s because there’s no hull penetration, resulting in less downtime off hire for the busy workboat or CTV.

While some estimates might put the cost of the fully integrated Volvo Penta system with all the bells and whistles at a 20% premium to another propulsion solution, it is not an apples-to-apples discussion. A one-supplier approach for any aspect of this system distills down to a “one party to blame” solution. Both Volvo Penta and N-O-S declined to describe it in that manner, but with the Professional IPS installation, there’s no other vendors to deal with. Truly the end of “finger pointing” when something might go wrong, the integrated IPS system requires one vendor to address any issues.

(Credit: Volvo Penta)

(Credit: Volvo Penta)

According to Inden, Volvo Penta does not design its equipment in a vacuum. Hence, their collaborative relationship with N-O-S is so very important. He added, “It is our partners who, in part, drive our innovation.” He continued, “We are creating something the customer doesn’t need today, but will likely want tomorrow.” Arguably, there is no better example of that philosophy than that which is embodied in the newest addition to the N-O-S fleet, the CTV Impresser.

Looking even further ahead, a hybrid battery equipped IPS allows longer tours at sea. The diesel engines provide safety and speed enroute, but once on station at a wind farm, the vessel can operate on electric only. This requirement is curiously opposite to the workboat model for sustainable tugs, where the “hour of power” requires the diesel engines when working, but not in transit or when idling. But the concept and goals are the same—no matter which application might be targeted.

For tour boat operations, customer can cruise in virtual silence, at ideal speeds of 5 knots for up to 3 hours, all with zero emissions in electric mode when in eco-sensitive areas. Before that, the operator can use superior range and top speeds in internal combustion mode when in transit to those sensitive areas. In recreational situations, people can live aboard, off-grid, in real comfort.

These IPS equipped vessels can operate in electric, hybrid or diesel modes. And, it’s the captain’s choice as to how and when to recharge the batteries. This can be done underway. But if not, then it can be done in port. What if there’s no charging station at your regular port of call? No problem: Volvo Penta will bring their modular containerized portable battery charging units to the dock of your choice. Need more power than one pod can provide? Two or three pods can be linked in parallel.

Looking further ahead, the next step in the green revolution involves offshore charging at the wind platform. Arguably, there can be no potentially greener energy solution on the horizon. Testing is underway, but the future looks promising indeed. If this evolves, look for both Volvo Penta and N-O-S to be there, ready to plug in the boats.

Volvo Penta’s innovative portable charging station solution. This pod can be pared in parallel with multiple units to augment and increase total charging capacity. A viable solution for leisure and remote fjord applications. (Credit: Joseph Keefe)

Volvo Penta’s innovative portable charging station solution. This pod can be pared in parallel with multiple units to augment and increase total charging capacity. A viable solution for leisure and remote fjord applications. (Credit: Joseph Keefe)

Finally, and in addition to the Volvo Penta IPS Professional Platform’s flexibility to adapt to future technologies and energy solutions, the enhanced maneuverability and thrust make it ideal for challenging conditions typically seen at offshore wind farms. Twin forward-facing counter-rotating propellers push water directly backward, creating a powerful thrust while reducing torque to enable more precise control over the I-Class vessel. The unique IPS system involves forward facing propellers that can accommodate twin, triple and quad arrangements. The props therefore can employ a full 40 degree turning radius, allowing the vessel to turn and literally “dance in place” on the water.

As industry moves toward having permanent offshore crews on board, and moving away from just dayshift work for larger fields, more robust, bigger and more capable vessels will be required. Today, there are 7,000 turbines on the water, but matching vessel size to the size of turbines is a big challenge, especially as wind moves further offshore. Newer turbines are bigger, demanding bigger boats that can perform in harsher conditions and for longer periods of time. Summer work may not be a luxury any longer. Winter work, therefore, requires a more robust and capable hull. It is no accident that N-O-S and Volvo Penta find themselves at the leading edge of this inevitable transition.

Inden explained, “There is no silver bullet solution, but this is a multi-faceted design.’’ IPS comes with options: the ability to use alternate fuels, electric motors and a hybrid approach. The savings quickly add up.

| Advantage: VOLVO PENTA | |

|---|---|

| IPS ‘helm-to-prop’ solution: | The interface is the driver to engines and props. One vendor for maintenance. |

| Electronics: | Volvo Penta employs in-house software for electronics. |

| Maneuvering: | IPS Professional version includes DPS & unique joystick assisted docking system. |

| Stabilizers: | Volvo Penta’s daughter company, Humphree, can provide stabilizers for a more comfortable ride – important when transporting non-mariner technicians. |

| Remote Monitoring: | Volvo Penta offers a two-year extension of the warrantee for a customer who agrees to share performance data. |

| Eco Mode Operations: | “Eco Mode” system decides how much power needed, balancing working hours on engines. Takes the pressure for fuel economy out of the mariner’s hands. |

Green Defined: it’s not so easy

In some circles, it is the holy grail of the tier 4 engine—whether IMO or EPA tier ratings—that define the final solution for operating in the most ecologically friendly mode. But, that’s not necessarily true. Certainly, for some tonnage, much of it in the blue water realm, a single engine propulsion solution makes a lot of sense. For a CTV out on station at the wind farm, not so much.

A single large engine approach works in many applications and works well when the engine is consistently used at its intended load and speeds. In the workboat realm, this is rarely the case. That’s why most two (or more) engine arrangements are more efficient. The loads can be balanced between the engines, reducing wear and tear and operating hours (prolonged engine life), and increasing time between planned maintenance intervals. In fact, Volvo Penta’s Tier 3 rated IPS engines can be rotated automatically on an hourly basis. The Professional IPS platform, therefore, is anything but a “tier beater” arrangement. When all of the variables are added up, IPS outperforms most Tier 4 engines in terms of environmental metrics.

The Volvo Penta IPS Professional Platform unlocks efficiency gains today with available internal combustion engine (ICE) solutions leveraging alternative or renewable fuel sources. Equipped I-Class vessel engines could potentially see up to 30% total fuel savings and emissions through the Eco Mode feature. These engines are even approved to run hydrotreated vegetable Oil (HVO) and have the potential to reduce emissions by up to 90%.

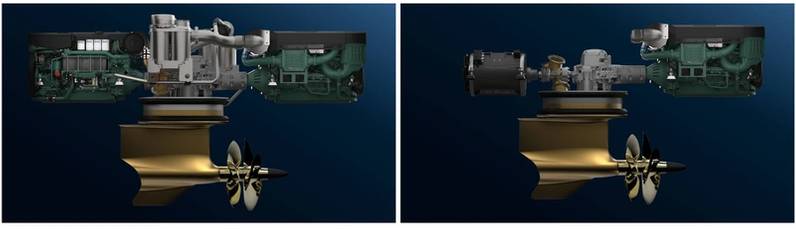

The IPS Professional Platform can be configure with traditional combustion engines or in a hybrid setup. (Credit Volvo Penta)

The IPS Professional Platform can be configure with traditional combustion engines or in a hybrid setup. (Credit Volvo Penta)

Incentivizing remote monitoring

The newest cutting-edge I-Class vessel is also equipped with a remote diagnostics package, which will capture more than 6,000 hours of data that will be incorporated into optimization and future Volvo Penta propulsion design. Remote monitoring isn’t a new concept by any means, but it is becoming more important every day. The ability to transmit this and other bytes of data has become simple enough to set up.

Less than 10 years ago, one prominent U.S. engine manufacturer told Marine News, “Today, remote monitoring systems for our engines is an option; five years from now it will be mandatory for all buyers.” Back then, resistance from operators was primarily rooted in the fear that engine OEMs would leverage user data to void warranties, should a major casualty occur. Volvo Penta also knows that not all users want to share data, hence they employ the “carrot,” rather than the “stick,” to incentivize customers. In this way, Volvo Penta adds a full two years to the standard warranty if their customer agrees to share data. It’s an attractive offer, one which N-O-S has also embraced.

Remote engine performance monitoring isn’t just about harvesting data, however. It is much more. Volvo Penta can, for example, send alerts to customers and their vessels when an engine parameter shows signs of wear or eminent catastrophic failure.

When it comes to unmanned engineering space control, it doesn’t get any more high-tech or convenient than Volvo Penta’s bridge mounted engineering control station. (Credit: Joseph Keefe)

When it comes to unmanned engineering space control, it doesn’t get any more high-tech or convenient than Volvo Penta’s bridge mounted engineering control station. (Credit: Joseph Keefe)

N-O-S looks ahead

“Green” is clearly a moving target. What was green previously may not qualify in the future. That creates serious risk for financiers, operators, and wind farm operators alike. To that end, N-O-S has addressed, if not embraced, some of that risk. This longer-term vision will deliver what Kristensson characterizes as “future proof” vessels—hulls that can be upgraded in terms of propulsion and environmental solutions—is just the ticket.

Drilling down further, N-O-S envisions a future that includes a 25-year lifespan for all their tonnage, whether achieved through repower or newbuild. This means anticipating and penetrating new offshore markets—wherever they currently exist or emerge—and embracing new technologies that advance a greener footprint, while creating more free space on board for core operations. The utilization of the most eco-friendly fuels and propulsion solutions will further lessen the carbon footprint of not only N-O-S, but also the industries that they serve.

If collaboration with Volvo Penta is, in part, a centerpiece of that ongoing modernization plan, N-O-S future-proofing doesn’t stop there. Take their proprietary, in-house designed “high grip fender,” for example. Vexed continually by the short life span of traditional and low-tech bow fendering equipment, N-O-S set out to develop their own five-piece system, which involves different materials for each segment, all of which can be replaced or serviced individually, or as one unit. Beyond that, the innovative and seemingly simple fix allows CTV vessels to push at the wind tower using less fuel and energy. By combining the omnidirectional propulsion system and the N-O-S, in-house designed High Grip Fender, operators can take advantage of the I-Class vessel to make safe journeys to further wind farms and safely offload and onboard technicians in any sea condition.

N-O-S’ innovative in-house designed five-piece High Grip Fender system. (Credit: N-O-S)

N-O-S’ innovative in-house designed five-piece High Grip Fender system. (Credit: N-O-S)

Across the big pond, and although the U.S. offshore wind market has stalled to a certain extent, N-O-S will be ready when it takes off again. In fact, its newest U.S. flag vessel, Generater, is soon to be delivered from well-regarded U.S. builder Metal Shark. Hence, says Kristensson, when the time comes for a more robust offshore U.S. wind market, “The U.S. will not make the same mistakes as Europe.” That’s because N-O-S brings lessons learned with them as they establish their nascent, and growing U.S. subsidiary, American Offshore Services (A-O-S).

(Credit: A-O-S)

(Credit: A-O-S)

The future is now

For the IPS Professional platform, Volvo Penta is targeting the 25-to-55-meter LOA market, a speed capability of 12 to 40 knots in the range of 2,060-5,880 kW installed power. That said, and in addition to its most recent application installed for N-O-S, more than 30 of today’s 67 N-O-S vessels are fitted with Volvo Penta equipment. It is just this kind of experience and track record that drives future collaboration, newbuilds, and retrofits for existing tonnage, as well.

Kristensson insists, “It is not easy to be first in any market or endeavor. This requires close collaboration with Flag and Class.” And, just maybe, their innovative propulsion partners at Volvo Penta. As Volvo Penta and N-O-S look ahead to a second I-Class vessel equipped with the Volvo Penta IPS Professional Platform, the sky is the limit, and the wind appears to be at their collective backs.