Ellicott Dredges, LLC announced contracts for three new custom-designed dredges, all scheduled to be delivered before the end of 2017.

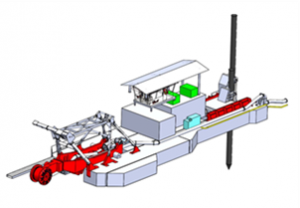

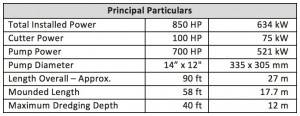

In the first instance a major international chemical company selected Ellicott to build a custom electric bucketwheel dredge to mine salt in a very hard digging application. The new dredge, which will increase the mine’s output per operating hour and reduce its cost per ton of salt produced, will become the mine’s primary dredge. The salt will be used as feedstock for various chemical products such as chlorine based PVC.

New features on the Ellicott Series B2190E dredge include:

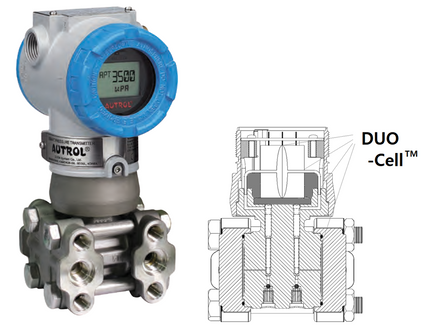

- A new hydraulic system, designed in-house, with the goal of reducing power consumption approximately 10 percent compared to existing systems

- Electric over hydraulic controls

- PLC onboard capable of collecting data and providing remote access to dredge controls and systems

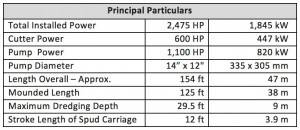

In the second case Barnstable County, Mass. has awarded a contract to Ellicott following a public tender. The new dredge will be used to maintain small harbors with beneficial reuse of the sand for beach restoration. The dredge represents a major step up from a smaller standard design Ellicott dredge, a Series 670 Dragon model named the “COD FISH," which Barnstable has operated reliably and satisfactorily for over 20 years.

New Features on the Barnstable County Series 850-S dredge include:

- Tier 3 compliant marine engine

- Inline drive train with a marine transmission

- A new hydraulic system, designed in-house, with the goal of reducing power and fuel consumption approximately 10 percent

- Electric over hydraulic controls

- IQAN and REDLION products used for in-house development of all control and visualization programming

- Fingertip controls with Joysticks mounted in the operator’s control chair

Finally, Ellicott announced that a major European chemical company has given it a contract to supply a small bucketwheel dredge to mine fertilizer feedstock.