There is increasing speculation regarding when the first unmanned cargo ship will set sail. The more important question is when will the first unmanned cargo ship spectacularly fail?

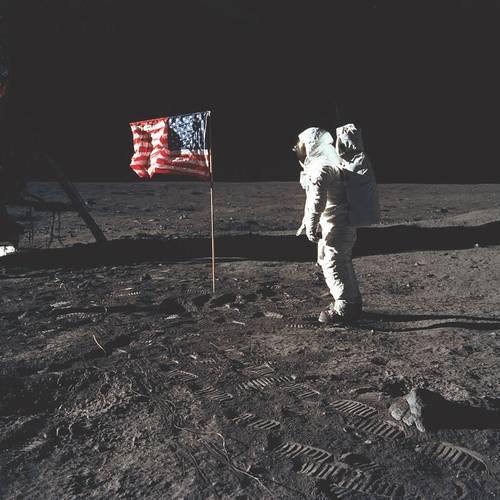

We (not me personally, but humans as a group) have utilized artificial intelligence to launch unmanned craft into space on increasingly long and complex voyages. Mostly, these space missions succeed and provide us with wonderful images and reams of important data. Therefore, it is theoretically and practically possible to construct and operate an unmanned cargo ship.

The difference between the unmanned space missions and a similar maritime mission is fundamental.

A space mission involves a large team of specialists working together for years. Assumptions are challenged and refined. Technology is pushed to the limit and beyond. Money is spent in truckloads. Tests are performed and analyzed. Triple and quadruple redundancies are built in. The rocket and payload are assembled with the highest degree of quality control. The rocket is launched. It mostly works now-a-days, but that was not true previously. Even after a successful launch, the space craft is monitored closely by a large team of experts who continually analyze the data and make corrections as needed. They are also available to reprogram the space craft and make course corrections as necessary when something goes wrong – a not infrequent event. Eventually, the space craft performs its mission (be it a fly-by past Pluto or an orbital mission around Jupiter). There are well-deserved congratulations all around and the public increasingly gets the impression that success is routine.

Even with all the checks, double-checks, and triple-checks, space missions do not always succeed.

•In 1999, NASA’s Mars Climate Orbiter burned up in the Martian atmosphere because the thrust of the maneuvering rockets on the orbiter had been calculated in metric units (newtons) while the mission team assumed that they had been calculated in English units (pounds).

•When launched in 1990, the Hubble Space Telescope provided only fuzzy images. Analysis revealed that the device used for the final grinding of the 2.4 meter mirror had been incorrectly assembled. The mirror had been ground very precisely, but to the wrong shape. It was only in 1993 after a risky space shuttle mission to install corrective lens that Hubble was fully able to fully explore space. The take-away is that few things go as planned.

•On December 14, 1996, the fully-loaded grain carrier Bright Field was downbound under pilotage on the Mississippi River passing through the Port of New Orleans. The main engine suddenly stopped. Exercising great skill, the pilot was able to guide the freighter into the Riverwalk promenade while sounding the ship’s whistle to alert those ashore. The allision into the promenade resulted in 66 injuries, but none was serious. Repair costs for the ship were $2 million and for the promenade and associated property $15 million. Investigation revealed that the engine was designed with an automatic shutdown in the event of low lubricating oil pressure. No one had thought through the ramifications of such an automatic shutdown on the safety of the ship.

•The U.K Royal Navy recently launched and placed into service a squadron of highly sophisticated Type 45 destroyers. The six warships, costing approximately $1.4 billion, have experienced repeated power outages because the gas turbine engines are unable to operate on extended deployments in warm water, such as that found in the Arabian Gulf. Pre-production planning and testing were obviously inadequate.

•On 7 May 2016, a Tesla Model S automobile collided with a tractor trailer on a highway outside Williston, Florida. The driver of the car died. Investigation revealed that the automobile was being operated in its driver-assist mode, meaning that it was guided by the on-board artificial intelligence system. Evidence indicates that the driver may not have been paying attention to the operation of the automobile as his DVD was heard playing a Harry Potter movie when individuals arrived at the scene of the casualty. It appears that the automobile’s guidance camera was unable to distinguish the white body of the tractor-trailer from the bright sky as there is no indication that the brakes were applied before impact.

The bottom line is that designers of machines, no matter how sophisticated, can’t anticipate and plan for every eventuality. They also can’t design and manufacture equipment and structures that will last forever and require no maintenance. Another thing we know is that no matter how many cautions accompany new labor-saving technology, users will invariably operate that technology beyond the published limits.

It is a fool’s errand to design and operate an unmanned ship over an extended period unless you are willing to devote the time, effort, manpower, and monies expended by organizations such as NASA. Such devotion will, by definition, make the venture unprofitable.

This is not to say that there is no place for artificial intelligence in the maritime industry. Humans cause the majority of marine casualties. Judicious use of artificial intelligence has proven the possibility of reducing the number and severity of those casualties. It must be recognized, though, that artificial intelligence, because it contains its own unique set of flaws, will also cause its own unique set of casualties.

There are numerous tasks that can be improved through the studied use of computers and related technology. Increased use of artificial intelligence, though, must be accompanied by increased training of crew members, whose tasks will be changed. For example, we quickly learned that Electronic Chart Display and Information Systems (ECDIS) cannot be installed in ships without providing detailed training to the crew members expected to utilize that computerized system. At the same time, basic maritime training for those crew members must not be jettisoned. Unless the mariner understands, for example, what information a maritime chart is expected to provide, ECDIS will be of no more value that a video game.

There are boundaries to human knowledge. These boundaries may expand over time, but they continue to exist. Artificial intelligence still relies on the skills of human programmers, engineers, and operators. We don’t know what we don’t know. While artificial intelligence is pushing the existing boundaries, stupidity and hubris are limitless!

The Author

Dennis L. Bryant is with Bryant’s Maritime Consulting, and a regular contributor to Maritime Reporter & Engineering News as well as online at MaritimeProfessional.com.

t: 1 352 692 5493