World’s First High Temperature Accelerometer Unveiled

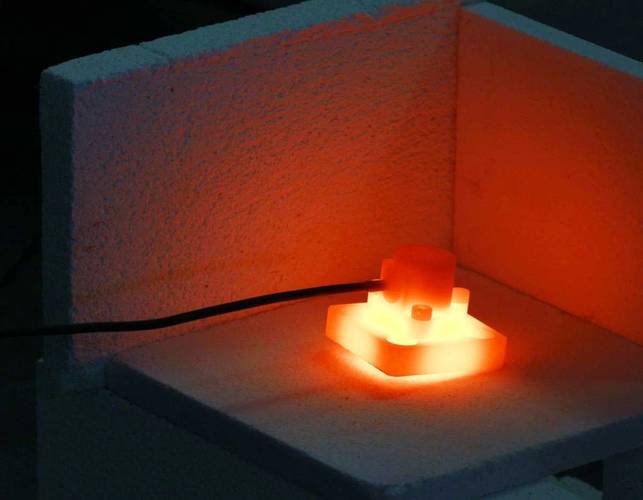

Kistler has introduced what it says is world’s first high temperature accelerometer for the monitoring of gas turbines. Designed for long-term use at up to 700° C, the piezoelectric sensor – made in Switzerland – is not pyroelectric and does not show any popcorn effect, offering manufacturers and operators of gas turbines new options for monitoring the combustion stability.

The efficient and secure operation of gas turbines relies upon stable combustion processes. These have to comply with increasingly strict regulations, including flexible operation on different fuels and minimal emissions. At the same time, there is an associated risk of unstable combustion processes and pressure pulsations. Reliable and continuous monitoring systems are required to monitor and control these combustion processes.

The new high temperature accelerometer is said to be the first sensor of its kind, designed for permanent operation with a lifespan of three to five years at temperatures up to 700° C.

Thanks to the patented PizeoStar crystal technology from Kistler, the new sensor is neither pyroelectric nor does it produce any popcorn effects. As a result, the sensor is reliable and generates high-quality signals for the interference-free monitoring of combustion dynamics, the manufacturer said.

“To begin with, our new high temperature accelerometer will be applied in research and development departments at scientific institutions. Additionally, we are also in direct contact with gas turbine manufacturers,” said Flavio Rosa, development engineer at Kistler.

The sensor completes the modular thermoacoustic portfolio from Kistler, including pressure sensors and accelerometers for long-term monitoring of gas turbines and combustion dynamics in high temperature surroundings.

High temperature sensors from Kistler are certified in accordance with the European ATEX guidelines for explosion prevention (Ex-nA and Ex-ia).