Thordon Bearings Unveils Solution for Wireless Bearing Condition Monitoring

Thordon Bearings has unveiled a new wireless propeller shaft bearing wear measurement system, marking a significant advancement in hull and propeller shaft condition monitoring.

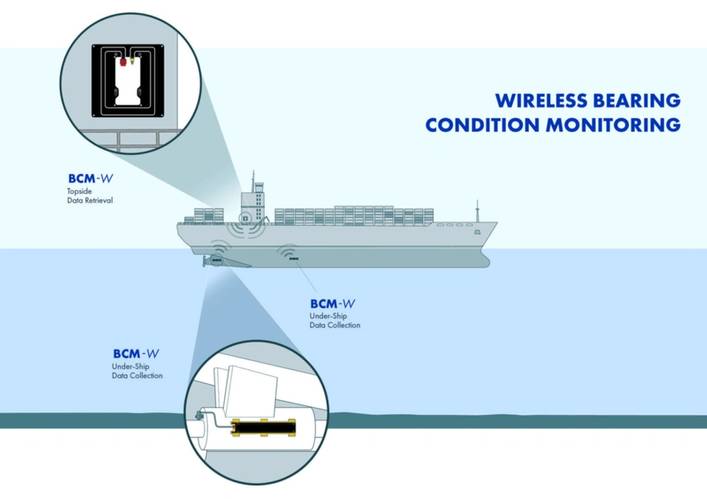

Developed in partnership with CSignum, a UK-based underwater communications specialist, Thordon’s Bearing Condition Monitoring – Wireless (BCM-W) system adopts patented electromagnetic field signaling (EMFS) technology to transfer data from underwater sensors to monitors positioned above the waterline.

The technology eliminates the need for the wired monitoring systems typically used to indicate the bearing clearance of seawater-lubricated propeller shaft bearings.

Traditional wired systems pose their own challenges for acquiring data and are not always possible to install without shaft withdrawal.

“Typical wired bearing condition monitoring systems can be installed during the newbuild stage, but unlikely to be used in retrofit applications as the shaft needs to be withdrawn to install the cable.

“Shaft withdrawal is not required with the BCM-W. It completely eliminates the need for cumbersome and penetrative cabling and removes the need for frequent and costly diver inspections,” said Anthony Hamilton, Thordon Bearings’ Technical Director.

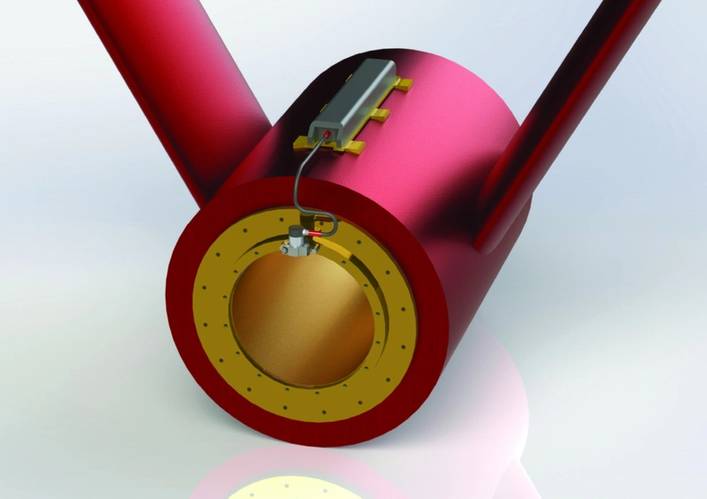

Simple to install in drydock or afloat, the BCM-W incorporates a non-intrusive sensor bolted on to the vessel’s sterntube and/or ‘A’ or ‘P’ bracket flange that is connected to the state-of-the-art subsea modem. Bearing clearance information is then transmitted to a topside modem data retrieval unit sited on an upper deck bulkhead. It is from here that ship operators upload bearing clearance data to a tablet or laptop.

While the Thordon BCM-W has been developed for seawater-lubricated bearing clearance monitoring, the technology can be easily integrated with other sensors to provide a more holistic view of the ship’s hull below the water line.