Thordon Bearings Unveils New Shaft Solution for Sterntubeless Ships

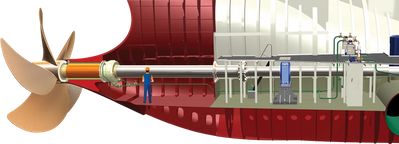

Representing a breakthrough in the evolution of a ship’s propeller shaft line, Canada’s Thordon Bearings has unveiled the Thordon-Blue Ocean Stern Space (T-BOSS), a new solution designed to meet the propeller shaft requirements of the sterntubeless ship design proposed by the Blue Ocean Alliance.

The Blue Ocean Alliance is a consortium of industry partners – ABS, Thordon Bearings Inc, Wärtsilä, SDARI, and the National Technical University of Athens (NTUA) – that have collaborated to develop and promote the sterntubeless ship concept

Thordon’s new T-BOSS propeller shaft arrangement includes the company’s COMPAC polymer bearing with tapered key set, Thordon Bearing Condition Monitoring system, a Wärtsilä Enviroguard shaft seal, and Thordon’s Water Quality Package.

Thordon’s Technical Director Anthony Hamilton said: “T-BOSS has been designed as a sterntubeless ship solution, which will replace the traditional sterntube system with a dry chamber, that will allow for the full range of inspection and maintenance activities for a seawater-lubricated single bearing and seal arrangement. These activities can be done while the vessel is afloat, thus avoiding the need for shaft withdrawal or drydocking. This has never before been possible.

“By creating an opening in the engine room bulkhead, adjusting stiffeners, shortening the intermediate shaft (allowing the main engine to be moved further aft), eliminating the sterntube, forward sterntube bearing and aft seal and installing the T-BOSS solution, shipbuilders can take advantage of reductions in material and labor costs, while ship operators benefit from significant OPEX savings. It is the most significant ship design intervention in more than a century.”

Aside from immediate savings in lubricating oil and elimination of the aft seal, shipowners opting for a T-BOSS sterntubeless ship could save more than $1 million in through-life operational costs, Thordon Bearings said, pointing to reduced fuel consumption, reduced drydocking and maintenance costs, and associated loss of earnings; shaft alignment optimization, lower bearing wear rates, better EEDI; and a potential increase in cargo carrying capacity. The arrangement also reduces the risk of environmental fines related to sterntube oil pollution to zero.

Dr. Chris Leontopoulos, Vice-President, Technology, EMEA, at ABS, a Blue Ocean Alliance partner, said that a T-BOSS ship’s simplicity of the arrangement, its maintenance, robustness and reduced environmental footprint, are astonishing. The design is fully ABS Rule compliant.”

An order for the first T-BOSS ship design could be close, according to Craig Carter, Thordon Bearings’ VP Business Development, who said the company has submitted quotes for T-BOSS to major shipbuilders in China and South Korea, for boxships and gas carriers. “Yards have been quick to see the commercial, operational and environmental advantages of a sterntubeless ship, compared to a design with a traditional oil-lubricated shaft line,” he said. “We have been asked to submit quotes for a number of newbuilds and anticipate orders soon.”

Dr. Chen Kang of SDARI (Shanghai Merchant Ship Design and Research Institute, CSSC), the naval architect firm that is part of the Blue Ocean Alliance, said, “Since 2022 when ABS granted Approval in Principle (AIP) for our sterntubeless container ship, there has been considerable market interest in the concept. We cannot underplay the importance of this concept in the maritime industry’s goal of reducing emissions. It offers naval architects, builders and ship managers greater freedom and flexibility for optimizing energy efficiency.”

In June 2024, ABS published guidelines for the Requirements for Sterntubeless Vessels with Water-Lubricated Bearings and introduced the ABS STBLess-W Notation.