Software Solutions Debuts & Upgrades

A Proliferation of innovative software solutions continues to make maritime operations more safe & efficient

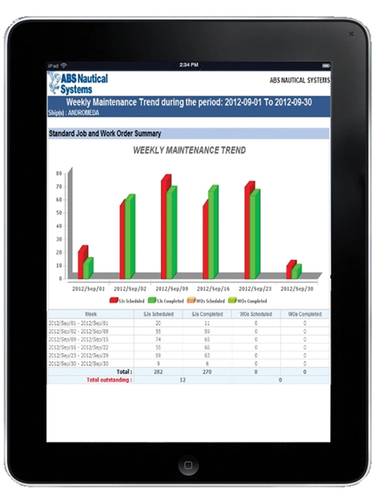

ABS Nautical Systems continually enhances its NS5 Enterprise software suite of products to meet ever-changing industry demands. Currently in development for release in 2013 are a mobility platform, a new warehouse and inventory management module, as well as a new Hull Inspection 3D module. The mobility platform supports portable devices including scanners, tablet PCs and smartphones. Features will include alert view notifications and mobile calendaring. Any customer with mobility support within the organization’s infrastructure can take advantage of this upcoming technology. The new warehouse and inventory management module will support standard inventory and reconciliation tracking. Features include a unified view of warehouses, vendors and freight forwarders, enabling users to track materials contracts, RFQ management, reporting and contract import/export. This module will also be supported by the upcoming mobility platform. The Hull Inspection 3D module includes 3D visualization with condition tracking, integration with the NS5 Hull Inspection web module, along with an integrated FEA interface.

ESRG has expanded OstiaEdge’s capabilities to include monitoring and analytics for torque/power meters and ballast systems, adding to OstiaEdge’s total ship monitoring and analytics package that enables ship owners and managers to use the existing onboard data to make better decisions and decrease downtime, optimize equipment performance and reduce energy costs. OstiaEdge combines torque and power analytics with engine and fuel flow analytics to provide operators with a holistic view of a ship’s fuel efficiency and equipment performance. Ballast system analytics enable operators to ensure compliance with ever-increasing environmental regulations. Torque meters and ballast systems add to a comprehensive library of systems that OstiaEdge monitors and analyzes, including: diesel engines, generators, compressors, gas turbines, water purification, refrigeration, HVAC and others.

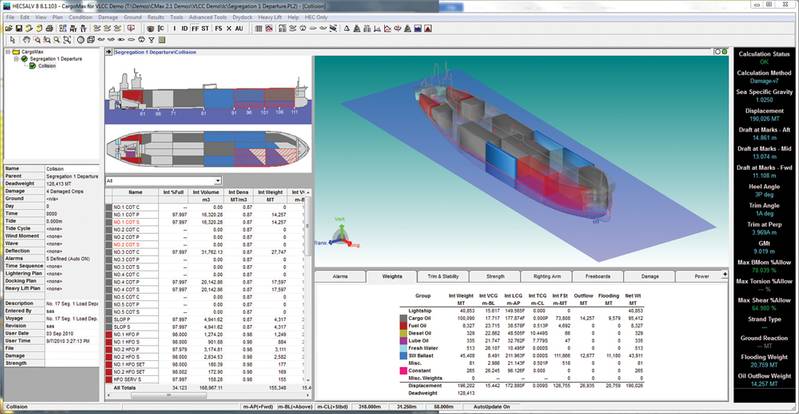

Herbert-ABS Software Solutions, recently launched HECSALV Version 8, Salvage and Emergency Response Software, which is designed to allow for rapid evaluation of damaged conditions for all ship types including an analysis of intact conditions, free-floating damage cases, oil outflow prediction and various types of groundings. The upgraded version features enhanced core calculations, a refined, more user-friendly interface, new 3D rendered graphics based on Hoops 3D, a variety of new modeling capabilities and is 100 % compatible with CargoMax 2.x and LMP 2.x. HECSALV is designed to allow users to quickly collect and process the available data, define the extreme bounds of the problem and evaluate multiple scenarios for remedial action. As more information is available, the user can quickly and automatically update the entire analysis from beginning assumptions to latter stage pump allocations. Additionally, HECSALV Offshore, a newly added component, includes all of the features embedded in the standard HECSALV 8.

AVEVA launched of the AVEVA Marine Business Value Calculator (BVC), an interactive application that illustrates the project cost savings, up to 30% across all disciplines, by adopting AVEVA’s Integrated Engineering & Design solution, AVEVA Marine. Based on data from authoritative industry sources and feedback from customers, the BVC is designed to enable users to project potential design and engineering cost savings as well as production man-hours and material savings when using the advanced discipline-specific modules from the AVEVA Marine portfolio as compared with Tribon. Existing AVEVA Marine customers will be able to see how they too can achieve further savings by using a broader selection of the marine portfolio.

By selecting the vessel type and size, the BVC employs a number of predefined criteria based on typical marine industry standards, including splits between materials and labor, design and production and hull and outfitting for different classes of vessel. Adjusting these input parameters to match a company’s existing cost structure on its typical types of project means that the BVC can provide a realistic projection of overall cost saving that that company could achieve.

The Asset Management Software AMOS2 Enterprise Management Suite owned and distributed by SpecTec Group, implements the KPI Module (Key Performance Indicators), in order to offer users the possibility to define, measure and report the company’s operational performance data against the Shipping Key Performance Indicators. The Shipping KPI Project is an industry-wide initiative which proposes a global shipping industry standard for defining, measuring and reporting information on operational performance. AMOS2 EMS 6.4.00 includes these new standards, but also allows users to define any other KPI requested or necessary.The module consists in a hierarchy of Performance Indicators (PI’s) which establishes the key performance indicators (KPI’s) used to calculate Shipping Performance Indicators (SPI’s).

Star Information Systems (SIS) introduces a new software module within the Star IPS suite handling advanced logistics. Star Warehouse and Shipment is a purpose made logistics module for handling multiple warehouses and shipments. The main features are:

Warehouses: The system facilitates for storing goods at a warehouse and makes this inventory viewable and “requestable” for a vessel, a group of vessels, or all vessels.

Packaging: It is possible to split e.g. one purchase order into different shipments so that some urgent spares are sent via air and the rest of the PO will be sent through normal sea freight.

Shipment: When the final box or container is ready for shipment the operator can create and print all required documents such as packing slips, dangerous goods labels and pro forma/customs invoices. SIS is also launching a new version of the office purchasing system – Star FSM 2.0. Star FSM has been built using the latest in IT technology and now also handles purchasing contracts and automation of purchasing processes.

Dynaflow, Inc. announces new developments in its 3DYNAFS CFD software suite. Enhanced general CFD capabilities are now available with specialization in interfacial flows, bubble dynamics, cavitation, two-phase flows, surface waves, ship hydrodynamics and fluid/structure interaction. Five major modules are available: a Boundary Element Method (BEM) module, a Viscous flow (VIS) module, a Discrete Singularity Method (DSM) module, a Fluid Structure Interaction (FSI) module and a Compressible flow (COMP) module.

Veson Nautical unveils its LNG module for IMOS (Integrated Maritime Operations System). A complete solution for LNG voyage management, the module is designed to enable operators to manage the chartering, operations, financials, and freight risk specific to the LNG sector. Its features include:

- Capture of Fuel Oil Equivalent (FOE) LNG consumption in contracts, operations, and voyage financials

- Consumption calculations based on configurable FOE speed/consumption tables with support for multiple consumption modes: LNG (natural and forced boil off), Dual Fuel, and IFO

- Automated transfer of LNG data via electronic vessel reports to shore-based IMOS system

- LNG vessel performance benchmarked against vessel/TCI/TCO consumption curves

Amarcon, a member of the ABB group, received an OCTOPUS-Onboard order for the new build Dockwise Vanguard, a large heavy lift vessel which was launched in November 2012 and is currently undergoing her sea trials. The Dockwise Vanguard will be equipped with OCTOPUS-Onboard for motion monitoring, response prediction and heavy-weather decision support during heavy cargo transportations. The vessel will also be equipped with a three sensor motion measurement set-up. This way multiple critical locations of the vessel, for instance the cargo, can be measured and displayed on the bridge of the vessel. The OCTOPUS product line is part of ABB’s Vessel Information and Control (VICO) systems suite which incorporates a full range of automation and advisory solutions specifically for marine applications, based on ABB’s field-proven process automation technologies.

Eco Marine Power (EMP) will use the KEI 3240 Data Logger supplied by KEI System Ltd (KEI) of Osaka, Japan, to verify fuel savings and measure the performance of its Aquarius MRE System – a wind and solar power solution for sustainable shipping. The KEI 3240 Data Logger is a flexible and robust marine computer based system that can collect and log various performance data for a vessel including engine power output. Hundreds of ships have already been fitted with the KEI 3240 Data Logger and the system has proven its reliability over many years. The KEI 3240 Data Logger can be installed on a variety of ships such as tug boats, cargo vessels and bulk carriers. It can also be retrofitted to ships already in operation or installed for example as part of a hybrid marine propulsion upgrade. The use of the KEI 3240 Data Logger will provide a ship’s crew with real time information regarding how much fuel consumption is being reduced through the use of Aquarius MRE System. This and other data can also be recorded and analyzed later.

HydroComp, Inc. has deployed a new CRP system analysis module into HydroComp NavCad, software for the prediction and analysis of vessel speed and power performance. Published comparisons of the efficiency between standard fixed-pitch propellers (FPP) and CRP propellers typically indicate that CRPs are between 3% and 10% more efficient. It is often presumed that the efficiency gains of a CRP are due solely to recovery of energy lost in the rotational flow of a single propeller. While recovery of rotational energy is partly responsible for the efficiency gains with a CRP, much of the gain actually occurs due to improved inflow and the reduction in propeller blade loading (with its corresponding change in RPM and blade area ratio).

HydroComp evaluated an extensive catalog of published studies that made direct comparison between FPP and CRP propellers. From the results of this evaluation, a new CRP performance prediction method was developed around a “system-level” model using only the representative definition of one propeller in the set to determine the overall system performance. The intent of the new CRP method is to reasonably predict the overall performance of a CRP “system.

(As published in the March 2013 edition of Maritime Reporter & Engineering News - www.marinelink.com)