The Smart Shipping Vision: Class Delivers

Shipping’s digital transformation is all around us, impacting the smallest vendor to the largest owner, across flag, class and shipyards, right up to the primary regulator.

In these early days, there are many competing visions of the digital future. But the central question for ship owners and operators should not be whether their partners are delivering the required solutions; it should be whether they themselves are undergoing the digital transformation of their operating models that will be required to benefit from a data-enabled maritime community.

In trying to assess the impact of digitalization, it’s important to recognize that shipping is a highly diverse industry composed of multiple market sectors, which have their own competitive pressures and are evolving at different depths and speeds.

There are, however, common threads. Many digital pilot projects are ongoing across the maritime industry, driven by desires to achieve community goals such as lower maintenance or fuel costs, the optimization of spares and components, the digitalization of processes and improvement of day rates.

Most early maritime adopters are coming from the energy-related sectors, where assets have high degrees of technical complexity. As more mainstream companies embrace the digitalization of their businesses, they must work to align their digital strategies with their desired business outcomes; investment decisions should be driven by core business requirements and market positioning, and so support their overall strategy.

Because digital and data strategies cut across broader industry goals – such as performance optimization, regulatory and environmental compliance, and cyber security -- it is essential that partners and suppliers align them with their desired business outcomes.

The Class Journey

The digital revolution will have a major impact on how class delivers its primary services. Our objective is the same as it has always been: to set standards for safety and excellence in design and construction. However, the process of how we deliver those services will be transformed, right from plan reviews to the services provided throughout the life of the asset.

A digitally enabled class strategy integrates four key elements to deliver services: connectivity, decision-making, efficiency and unlocking the power of data.

It is underpinned by a simple premise: supporting clients from vessel design through to operations and maintenance requires class to develop and deploy a lifecycle strategy for data. Data use cannot be limited to operations alone, because lessons learned along the way should impact the next generation of vessel designs.

We need to be focused on creating new solutions that streamline the connection to client data, leading the way to a digitally enabled relationship.

We believe that the class experience – for clients and other stakeholders – is about to change significantly. Some operators are just beginning to understand what it means to treat data as a valuable asset, while others already appreciate its importance. Even though the concept of ‘big data’ has been on our radar screens for more than a decade now, for most, meaningful engagement has only just begun.

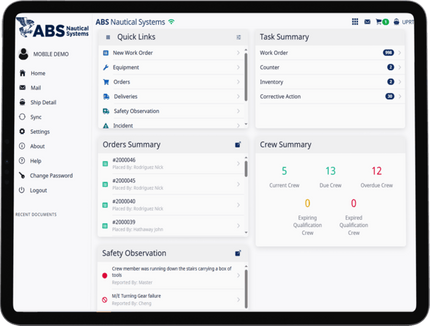

Exhaustive research with shipowners, vendors and shipyards is required to understand their data challenges. Any interface offered by class must offer access to everything an owner or operator needs to know – such as fleet status, operating statistics, certification, which ships are due for survey, as well as comments from the engineering department.

Creating Value

What is clear is that a non-integrated approach to digital investment will not work. A lifecycle strategy will require class to work in partnership with vendors and clients, using a more connected model. Only then can industry use data to improve asset and performance management, maximizing the skillsets of all parties.

Ultimately, this process will allow class surveys to transition from today’s calendar-based approach to something that is more data, or necessity-driven. Not too many years ago, it’s fair to say, some owners viewed class as a potential ‘inhibitor’ of operations, offering restrictive interpretation of its own rules. Now, many understand that a partnership with class supports, not restricts, their operations and helps them to work smarter.

There are multiple elements to the digitalization of class, but the fundamentals are simple: improve connectivity to provide a single portal for survey and compliance information; provide surveyors with new inspection and data-driven decision tools; provide crew and superintendents with voyage and operational support; and create a data platform that helps class to build new applications in a collaborative way. The first goal for survey and maintenance is to make decision making more reliable and efficient. At our recent annual meeting, we held a live demonstration of a surveyor in the field working with a support engineer back in the office. The surveyor had a technical issue on board the ship.

Using a wearable device, the surveyor shared her view of the problem area with the support engineer. The support engineer captured an image of the problem area, recorded it (capturing it for reference in the next survey), shared rules, drawings and advice in real time. Soon, this type of technology-driven service will become standard practice, much like screen sharing with a virtual help desk.

Supporting Operations

Efforts to improve class’s digital efficiency are already underway; e-certificates are already being delivered on-demand in a secure environment. To support environmental compliance and manage maintenance activities during daily operations requires reliable, automated data capture with replication to the shore for further analysis and interpretation.

The enterprise resource planning tools required for this will need to capture large volumes of transactional data, which then can be used to create actionable information to better manage vessels. To drive more effective decision-making, class is focused on delivering business-intelligence tools across applications that support everything from compliance and performance efficiency to health, safety, quality and environmental management.

The emergence of mobile and cloud-based apps is supporting that transition, but they need to be market-specific for areas such as merchant shipping and workboat sectors and able to enhance operations onboard and ashore.

A Condition-Based Future

The future lies – and where ABS is already delivering new services – is in condition-based classification (CBC). This transition reflects the owner’s focus on improving asset reliability and availability to meet commercial goals, while continuously enhancing safety.

CBC uses data and analytics to generate a lifecycle-maintenance program. It is moving towards planned and, ultimately, preventative maintenance regimes that help to detect the anomalies that can contribute to operational failures before they happen.

It is a phased journey, with the first step aligning the vessel-maintenance cycle and the class cycle to replace the calendar-based schedule with a condition-based process.

The next phase entails data gathering from multiple sources and data cleansing to improve the quality of the analysis. The last part is important because a significant amount of data that is collected from vessels today is not effectively used; cleansing identifies data-quality problems. Once these problems are understood, it is possible to develop applications to filter data and fix issues.

The third phase is developing models to enable predictive maintenance based on the detection of anomalies and machine-learning algorithms. When shipowners align their digital strategy to achieve key performance indicators it allows them to use advanced data analytics, machine learning and artificial intelligence to identify potential operational issues and reduce the disruptive and expensive failures that can result in lost revenues.

We recently announced a two-year CBC project with the US Navy’s Military Sealift Command; similar projects are advancing with merchant shipping and offshore clients. As it develops, CBC will provide an opportunity to not just improve the maintenance and performance cycles, but also make the quantum leap of designing smarter ships by using the lifecycle approach to data.

Another Step Forward

Class is already moving into the world of the cloud-based platforms, which can be used to build and deliver digital applications. In a maritime world that is increasingly defined by platforms, we are working closely with clients on specific business issues to provide targeted solutions.

A key to the success of maritime digitalization is the question of data ownership. We are very clear that the data belongs to the client, and it will be used under license; they need to be completely confident that they can share data in a protected format that will be anonymized to gain insights that will benefit all industry stakeholders. For ABS, it is not a case of ‘give us all your data and we will sell you services’. We don’t think the role of class is to be the ‘Maritime Amazon’.

Modern industry stakeholders, who have already started down the path to digitalization, believe we should focus on building solutions that solve their problems in innovative ways. Longer term, there will be varied solutions, but owner issues will remain similar; connecting to the industry allows us to tailor outcomes. The journey is going to be fast paced and exciting. A digitally enabled class will be more effective, efficient, informed and flexible. It will allow class can adapt to meet the needs and expectations of industry as they evolve, while using the transformation we are undergoing to predict and anticipate them too.