SL-7 Container Ships & An Engineering Myth Busted

The Rolling Stones were wrong: Time is not on my side.

Too often a myth is created and if not killed off right away, it will take on a life of its own and time will not debunk it. Many myths are created for evil or political purposes, but some myths just occur because the truth is just too complicated.

Some of those myths don’t even make sense, but there is no available data to establish the truth.

As a very young engineer I was told that the aft accommodations of the SL-7 container ships were installed backwards. They sure look backwards, and having accommodation doors face a 40 mph headwind made no sense. But why would they be installed backwards? Over the last 40 years I raised this subject with at least a dozen Sea-Landers and all confirmed it. When I asked why, most said they did not know, or defaulted to the classic “because engineers designed it”.

At best, I received vague answers such as the first house was preassembled and when they wanted to fit it on the hull, they could not rotate it so they redesigned all eight vessels to have backwards houses. That made no sense, but as a young engineer you can ask only so many questions before more senior engineers tell you to get back to work.

Image courtesy the Author

Image courtesy the Author

So, I was left to ponder this issue during dark stormy nights when my wife told me it was my turn to change the baby’s diaper for once. Or later in life, when I woke up wondering whether to get out of bed to get a handful of Tums, or just ride the indigestion out. Time was not on my side, because with the passing years who would be left that knew the truth?

That all turned upside down while working on the SL7expo project, when Raj Sengupta told me the designer of the SL-7’s is still alive. John Boylston, who was the primary designer of the SL-7’s when he was still in his twenties, provided us with some incredibly valuable information on the design of these vessels.

But nothing on backwards aft houses.

After a few emails on other subjects, I finally screwed up my courage and raised the subject.

John responded, and I provide the truth in his own words:

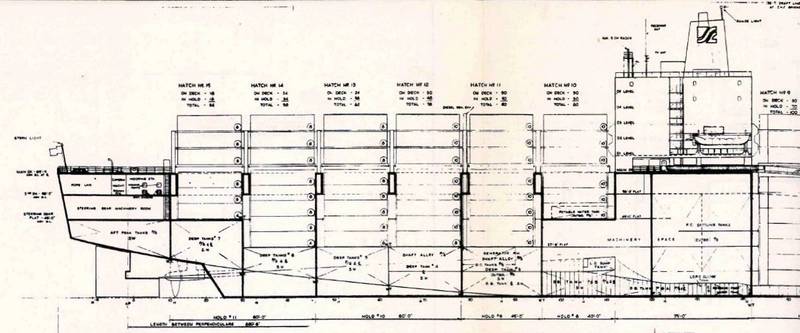

- While an interesting story, it is incorrect. To see why, you need an inboard profile. You can see where the turbines are located, they are located as far aft as possible. This was because the shaft lines, if kept short as possible would only affect the height of aft stowed containers below deck, as the shaft line dictates where the bottom of the aft hatches are located.

It was desirable not to have too many containers aft as the fine shape of the hull, particularly aft, provided limited buoyancy and too much load back there would require forward ballasting. The fine lines of the ship, a block coefficient close to 0.5, also made the ship incredibly deadweight limited so, in operation, a ton of fuel used was replaced with a ton of ballast.

The GM of the ship loaded had a quarter inch of margin so keeping weight low was a requirement as the ship made passage. This then required that the boilers be placed forward of the turbines, as to place them aft of the turbines, not only affected trim, but stability as the boilers would have had to be raised above the shaft line.

With both 35 foot and 40-foot cells forward of the forward engine room bulkhead, we could just get the number of cells required to meet overall container capacity. The boilers were oversized as operations required the ship to operate at 80% power on one boiler in case one boiler went down.

They also required antique D type boilers as that is all the engineers, in the fleet of WWII converted tonnage, knew how to operate. I thought both of these decisions absurd, as they compromised a difficult design even more. You can see the boilers are so huge they come through the main deck.

Boilers providing steam to 120,000 HP of turbines require a lot of air, so the forward location was so arranged that the front of the house lined up with the forward ER bulkhead and air entered from the forward house bulkhead, providing better flow to the forced draft fans. Attempting to get air into the boilers from the side of the house at almost 40 mph would have required huge scoops which would have added drag we hardly needed. Wind tunnel tests showed that with full containers on deck the air flow went over the top of the house, so a flat forward house front did not affect drag.

With all the equipment needed for the forced draft and other associated boiler auxiliaries in the forward house set in there, we found we could narrow the house enough to get lifeboat stowage on either side of that house structure. This was important as to get all accommodation into the length left between the forward ER bulkhead (or last forward cell aft bulkhead) and the forward bulkhead of what was desired for the first aft container stow, we needed a narrow accommodation block, forward and aft, and thus could go to the full beam of the ship to get the accommodation fitted. You can see it comes out to the side of the ship.

In a USCG decision made during construction that really annoyed me, the secondary set of access from the decks of the accommodation (a series of vertical ladders that was approved by the USCG in drawing approval), was rescinded and balconies had to be fitted. Similar to the house front wind tunnel tests, those tests showed the airflow, as designed, would not be affected by the accommodation bump out past the forward section of the house and the balconies somewhat screwed that up for us.

We still did 34.2 knots in one fully loaded run.

Myth busted!

And what is most telling is that, once again, the truth is much more complicated than the myth. Thank you, John; for designing these great ships, and for finally allowing me to sleep more peacefully.

In the spirit of this column, I suppose I should also note that the Stones neither wrote nor first recorded “Time is on my side”. The song was written by Jerry Ragovoy, who wrote the title, melody and chorus. Kai Winding, a Danish-American jazz trombonist, and Newark Nightingales Dee Dee Warwick, Dionne Warwick and Cissy Houston (Yes, Whitney’s mother) recorded it. The song was released on the Verve Records label in October 1963 and received some radio coverage but did not chart.

There; another myth busted.

For each column I write, MREN has agreed to make a small donation to an organization of my choice. For this column I choose Holiday Express, a group of musicians and volunteers that has been providing human kindness since 1993.