Shipshave’s ITCH Put to the Test

Independent laboratory testing reportedly confirmed there is no decrease in the thickness of hull coatings from the use of Shipshave’s In-Transit Cleaning of Hulls (ITCH) solution, according to the company.

The Endures laboratory in the Netherlands was enlisted by Norwegian technology developer Shipshave to perform tests to investigate the impact on the thickness and roughness of anti-fouling coatings from repeated brushing with the ITCH system.

A number of coated panels treated with two main anti-fouling coatings - self-polishing copolymers (SPC) and fouling release coatings (FRC) - from three suppliers were exposed to natural sea water over a two-month period and then subjected to a test simulating one year of monthly proactive cleaning, with the layer thickness and surface roughness of the coating measured before, during and after cleaning.

Testing was carried out using four different brushes with varying fiber thickness placed at different angles on the ITCH system.

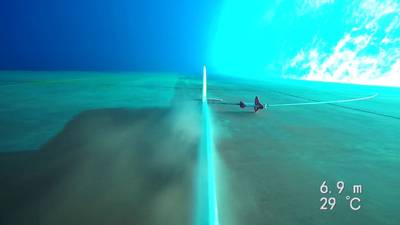

The semi-autonomous hull-cleaning robot, which can be deployed by a ship’s crew from a portable winch mounted on the forecastle deck, swipes up and down the hull underwater in transit using hydrodynamic energy to remain attached to the hull.

The newly published test report concluded that “no decrease in coating thickness could be found for all brush types used on all coatings” and therefore that “the ITCH can be used as a tool to remove fouling as it does not influence or reduce the coating thickness”.

The testing did show some increase in surface roughness, with no further increase after initial brushing, but the resulting roughness was still within what is considered acceptable for a well-performing, freshly coated hull. Consequently, the “increase in roughness is neglectable from a hydrodynamical point of view”, according to the report.

Shipshave’s CEO Aage Hoejmark. Photo: Shipshave

Shipshave’s CEO Aage Hoejmark. Photo: Shipshave