The OBA ShipCheck Fluids Analyzer

Automated Technology Provides Lab-Quality Fluids Analysis On Board and In Minutes

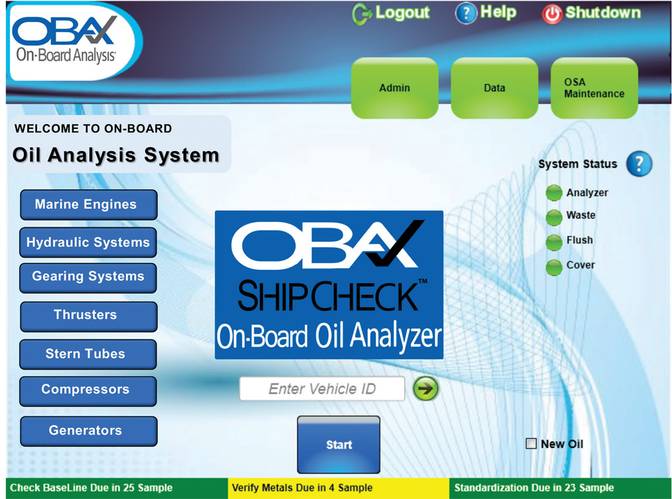

Privately held, American-based On-Site Analysis, Inc. (OSA), a manufacturer of high-tech, on-premise, automated fluids analysis equipment, has now expanded into the maritime industry with the introduction of the OBA ShipCheck, an on-board analyzer. With a physical footprint of just four square feet and weighing only 95 pounds, and using the same ASTM methods as outside labs, the OBA ShipCheck conducts diagnostic fluids analysis for marine engine lubricants, marine grease and gear lubricants, generators, hydraulics, air compressors, scrape down oils and many more fluids. The device allows engine room staff to perform comprehensive fluids testing on board and in just minutes to identify needed repairs – eliminating the need to send samples to onshore laboratories.

The proprietary technology utilizes advanced analytical components including a built-in dual temperature viscometer and particle counter. The OBA ShipCheck conducts lab quality diagnostic analysis of all lubricants, hydraulics, gear boxes, transmissions, generator lubes, etc. Automatically identifying the presence and/or levels of 20 metals and contaminants like glycol, fuel, % water, Nitration, Oxidation, Dual Temperature Viscosity (40 & 100c), it also identifies the fluid’s Total Base Number (TBN). The OBA ShipCheck’s special software has been customized to marine application rules, with an extensive database reflecting the industry’s concentration in hydraulics and gearboxes. This information is then used to identify if fluids have been over extended, still have physical properties, or if component has a needed repair.

Designed to allow engineers to do their own analysis, OBA ShipCheck does not require expert staffing. As a start, the device eliminates the need – at just 25 percent of the cost – to send fluid samples to onshore laboratories. As the centerpiece of an effective condition-based maintenance system, the OBA ShipCheck connects directly to the LubeTrak web-based data analysis system, allowing corporate fleet maintenance management to track the condition of their entire fleet on a real time basis and receive email “Alerts” when emerging problems are identified. According to Jim Greer, President of On-Site Analysis, the equipment is robust and dependable. He explains, “For years, mining and ocean oil-rig operators in remote locations have used it to test all of their lubricants.” Will Willis, Jr., Chairman & CEO, adds, “We can virtually eliminate 100% of the unscheduled repairs brought on by not monitoring the internal conditions of components and fluids. By conducting on-board analysis, maintenance people can identify hidden or emerging problems before they become catastrophic. Additionally, they would not do unnecessary fluids changes or maintenance because our analyzer will tell them when something needs to be done. Shipboard personnel would benefit by implementing a condition-based maintenance protocol and avoid of the lost time and money associated with breakdowns.”

OSA claims that personnel can be trained to be certified OBA ShipCheck operators in less than one day. Beyond this, a fully loaded OSA ShipCheck, with LifeTime remote technical support, Installation & training, Spare parts and tools kits, consumables for 200 tests, printer, wireless card, back up battery and unlimited access to a web-based data mining, trending, and monitoring system will cost less than $100,000 – or somewhat less than what a main engine failure at the wrong time and place might do to your bottom line.

Every unit downloads to LubeTrak, a web based, password protected sample monitoring, trending, and management system, so someone at corporate can monitor every ship in the fleet. E-mail ‘Alerts’ are sent if anything abnormal is discovered. As easy to use as an ATM, ShipCheck provides results in minutes where you need it most; on board.

www.on-siteanalysis.com

(As published in the December 2014 edition of Marine News - http://magazines.marinelink.com/Magazines/MaritimeNews)