New Book: Cost Management in Shipbuilding

Global competition in the shipbuilding industry, which is continuously intensifying due to the entry of developing countries into the shipbuilding market, leads to decreasing margins and enormous cost pressure in this industry. Many shipyards have already gone bankrupt through the inability to keep to their original budget that the offer was based on. In the naval sector it is not unusual to double the originally estimated costs when building the vessel. The first oil crises in the 1970’s and later oil price increases have substantially increased the importance of operating costs and the life cycle costs. Even if the significance of operating costs has sometimes temporarily waned in the face of periodic price reductions, the current state of limited resources now requires the integration of the entire life cycle of a ship into cost management.

These circumstances are forcing shipyards to implement effective cost management during product development and manufacture. However, the difficulty in shipbuilding cost management is that the majority of costs for a ship have already been defined before the start of production. Therefore, a cost management system implemented during the initial design and design engineering phases is especially effective. The information about estimated costs for the ship and its elements, such as components or systems, should be obtained and incorporated into the decision-making process in order to capitalize on its potential. In reality, however, the available cost information at the beginning of the project is usually incomplete and imprecise, making cost management during the early phases highly complex and elaborate. Simultaneously the pressure of time limits leads to difficulties with determining exact and robust cost information. Last but not least, the existing data base, generated in past projects, is far from complete, caused by the lack of an integrated system for managing and providing the cost information. Therefore, the shipbuilding process requires special cost management procedures.

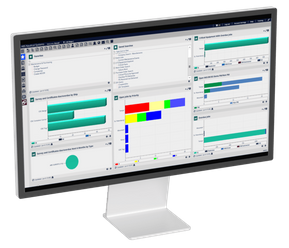

Against this background the authors of the book “Cost Management in Shipbuilding” demonstrate how effective cost management methods and processes strengthen and ensure a manufacturer’s competitiveness in the maritime industry. To do so, the authors first provide an overview of the current state of cost management in the shipbuilding industry, presenting the relevant terminology and methodological principles and showing the weak points in current methods, processes and systems. The book then shows how planning, analysis and management of costs should ideally occur. This takes place with a main focus on the cost management system “costfact”. This system has been developed specially for the maritime industry and enables users to capitalize on the enormous potential arising from cost-oriented design and engineering.

The chapters of the book contain the following procedures, methods and the corresponding support the costfact system offers:

- Planning of the costs according to the ship’s building structure, both top down and bottom up.

- Cost estimations for new projects based on existing calculations by deriving the costs of new objects from those of existing components and assemblies.

- Parametric cost estimation: Determining cost functions, based on a statistical examination and validation of the technical and economical characteristics of existing objects.

- Structured and simplified specification creation which is supported by the costfact system’s ability of importing, structuring and working on specifications as well as checking the consistency of specifications and cost prognoses.

- Risk analysis to calculate the extent to which future real costs could deviate from forecasted costs.

- Cost driver analysis based on Pareto’s law to determine the cost drivers that have the biggest influence on these costs.

- Analysis of the costs caused by a change in the customer demands.

An especial advantage of the costfact system which is described in this context is that it supports cost management throughout all project phases. Cost planning and control can be carried out at various analysis levels based on the information available. Various sources of cost information for the different levels can be utilized, such as calculated planning values or actual costs from previous and current projects.

In addition to optimize production costs incurred before the ship is operational, managing life cycle costs is also key in shipbuilding. Life cycle costs are the various costs the product user incurs through the purchase and utilization of the product. Since, a ship’s purchase price often (depending on the ship type) comprises only a small portion of the total life cycle costs for the customer, it is not enough to only optimize production costs. When evaluating design concepts, shipbuilding companies should also take the sometimes contradictory effect on production costs vs. life cycle costs into account as well as how any adjustments will be perceived by the customer. The authors describe how life cycle costs can be calculated based on an estimation of all expenses in the ship’s life cycle. In this context a focus is on the comparison of alternative projects respectively technical variants of a project. Moreover, the consideration of effects by uncertainties of the in-service phase parameters is illustrated in detail.

The book is based on knowledge, which the authors gained by more than 10 years experience in industrial cost management and shipbuilding and addresses specialists confronted with the practical challenges of cost management in everyday business.

Cost Management in Shipbuilding - Planning, Analysing and Controlling Product Cost in the Maritime Industry,

Jan O. Fischer, Gerd Holbach,

GKP Publishing, Cologne 2011

196 p. 101 ilus.,

ISBN: 978-3-00-033225-8