Schoellhorn-Albrecht Delivers Deck Machinery Package

Schoellhorn-Albrecht recently delivered [1] Anchor Windlass suitable for use with 2” anchor chain, and [6] Mooring Winches for use with 7/8” to 1-1/8” Wire Rope, to be used on the Cleveland Rocks Conversion to a Self-Unloading Cement Carrier.

Design Characteristics of Machinery:

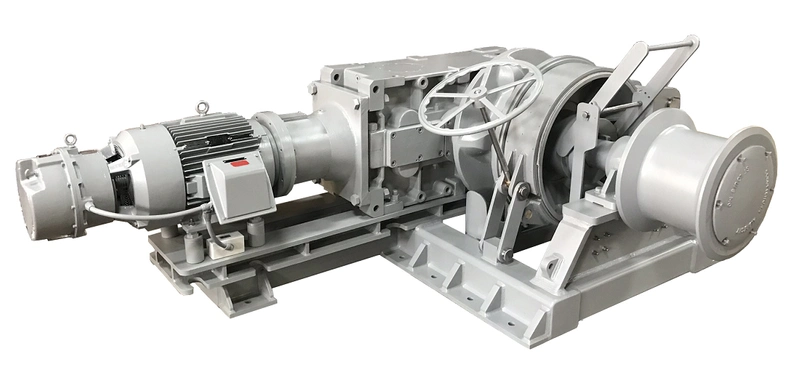

Anchor Windlass: The Anchor Windlass was fabricated with a 2” wildcat, a manual band-brake, a wildcat clutch, an Ø18” warping head, a chain stripper, and an integrated pawl-type chain stopper. Powered by a 2-speed 25/25HP Electric Motor, the Anchor Windlass provides a continuous chain pull of 24,600 LBS at 30 feet per minute, and an overload chain pull of 36,900 LBS at 15 feet per minute. The Anchor Windlass is operated with a NEMA 4X 5-button pendant mounted in a custom protective clamshell pedestal.

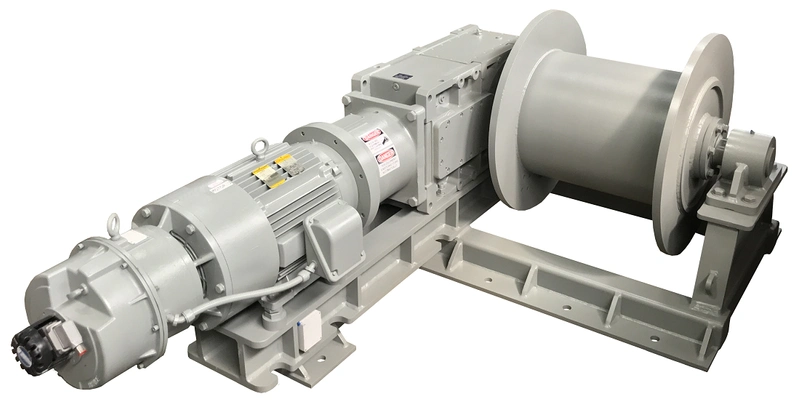

Mooring Winches: Each of the Mooring Winches are fabricated with a Ø22” drum and 600’ of storage capacity for between 7/8” and 1-1/8” wire rope. The Winches were designed to be used with the wire rope pulling in either direction and being under-wound or over-wound on the drum.

Each of the Winches are powered by a 50HP Electric Motor and an accompanying variable frequency drive. With the benefit of the VFD the Winches are capable of a continuous line pull of 15,000 LBS at 0 to 100 feet per minute, a starting line pull of 21,000 LBS, and a light line pull at up to 150 feet per minute.

The Winches are operated with a NEMA 4X multi-button control panel mounted in a custom protective clamshell pedestal. The control panels can communicate with one another and which allows for a constant tensioning application whereby the operator can travel the vessel by manually altering a pull on one Winch while the other Winches compensate for the tension by paying out or hauling in wire rope.