Sandock Austral Shipyards Offering Container Feeder Barge Concept

A new port container barge concept being offered by Durban's Sandock Austral Shipyards aims to improve the way containers are handled in South Africa’s ports, ultimately leading to less road congestion and faster turnaround times for imports and exports.

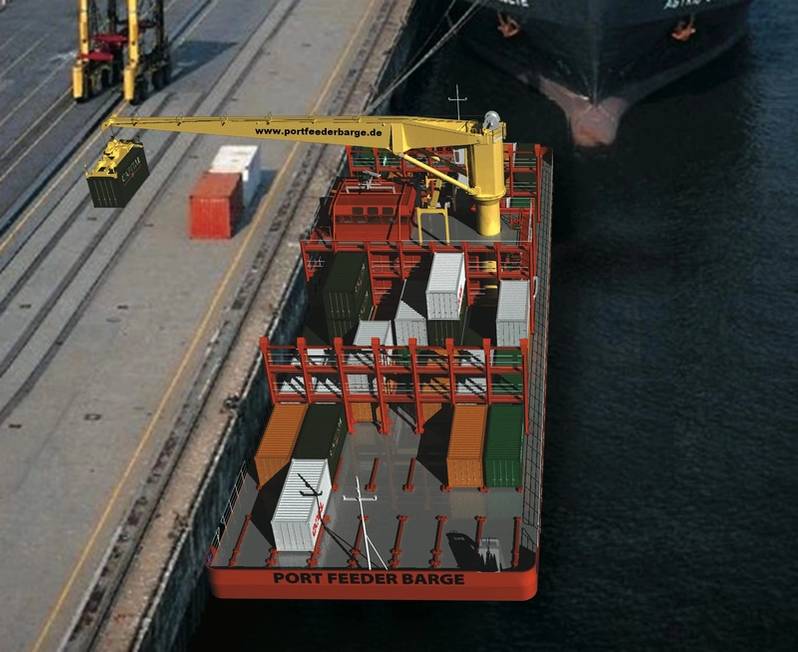

The internationally patented, German-designed self-propelled and self-sustained Port Feeder Barge can be deployed at a moment’s notice to wherever it is needed and can operate easily in low water depth or high berth. The barge is independent from quayside equipment and can be used to move containers from different handling facilities shifted from road to waterway.

It is also equipped with its own full scale container crane, “While it looks like a standard shipboard crane, all its mechanical components have been especially designed for continuous operation. Due to its nature, the Port Feeder Barge is continuously in port – seven days a week. Hence the load cycle requirements are even higher than for many quayside cranes, which have significant consequences on the layout of its mechanical components,” said Dr. Ulrich Malchow, whose company designed the Port Feeder Barge.

Compared to trucking, the Port Feeder Barge does not cause any additional work for the deep-sea terminal. Instead of carrying a container to the pick-up area for the trucks a terminal vehicle carries it to any quayside zone in terminal's option.

The Port Feeder Barge also helps to reduce carbon emissions as it eliminates the need of extensive travelling of trucks in the port. “Durban, like Lagos or even Hamburg has a lot of container movement within the port from one terminal to another which requires the use of trucks. Furthermore containers need to be carried for stuffing and stripping activities to off-dock facilities which often have their own (shallow) water access, but no cranes, resulting in additional road haulage. The Port Feeder Barge eliminates this so there is less traffic congestion and moreover reduces the carbon emissions,” Dr. Malchow explained. “As a whole, the Port Feeder Barge is environmentally friendly and economically cost effective.”

Dr. Malchow said the Port Feeder Barge has myriad of uses as it can be deployed as a 'Floating (and self-sustained) container truck' for the haulage within ports or to nearby locations (e.g. container freight stations) or as a ‘Floating terminal' for deep sea container vessels at anchorage, coastal shipping or inland navigation. It can be used even as a floating crane for non-containerized cargo.

Suhaila Gobey, Marketing Officer at Sandock Austral Shipyards, said that this hybrid concept is an eco-friendly logistic innovation for ports that could help to ease congestion and reduce the environmental impact of heavy container trucking in many container ports.

“Sandock Austral Shipyards signed this agreement to introduce the design in order to considerably improve the internal container logistics in many major and minor container ports. By introducing such type of vessel, midstream operation becomes much more efficient and cost effective to the operators. Collaboration and cooperation is the forefront of our organization and we look forward to introducing this niche solution to all major ports worldwide,” Gobey said.

(Image: Sandock Austral Shipyards)How it works

(Image: Sandock Austral Shipyards)How it works

The internationally patented Port Feeder Barge concept is a self-propelled container pontoon with a capacity of 168 TEU (completely stowed on the weather deck), equipped with its own state-of-the-art heavy-duty container crane mounted on a high column. The crane is equipped with an automatic spreader, retractable from 20ft to 45ft, including a turning device. A telescopic over height frame is carried along on board. The barge is of double-ended configuration, intended to make it extremely flexible in connection with the sideward mounted crane. Due to the wide beam of the vessel no operational (stability) restrictions for the crane shall occur. The crane has a capacity of 40 tons under the spreader, at an outreach of 27 meters (maximum outreach: 29 m). The unique vessel is equipped with 2 electrically driven rudder propellers at each end in order to achieve excellent maneuverability and the same speed in both directions. While half of the containers are secured by cell guides, the other half is not, enabling the vessel to carry also containers in excess of 40ft as well as any over dimensional boxes. The vessel shall fulfil the highest environmental standards. A diesel-electric engine plant with low exhaust emissions has been chosen to supply the power either for propulsion or crane operation. The vessel can be operated by a minimum crew of three.