Rolls-Royce Unveils New Podded Propulsion Range

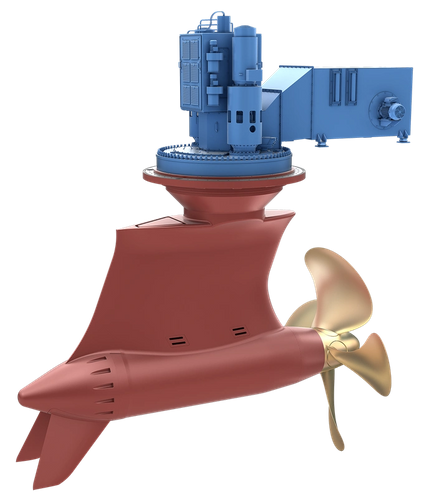

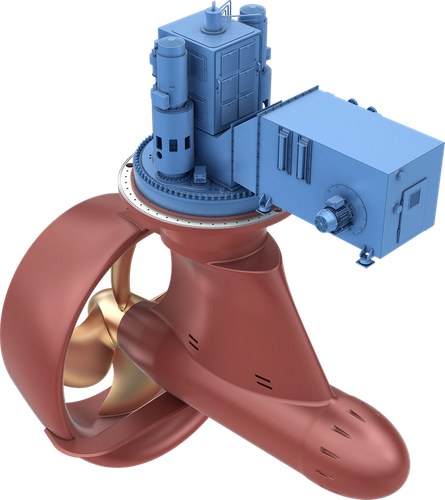

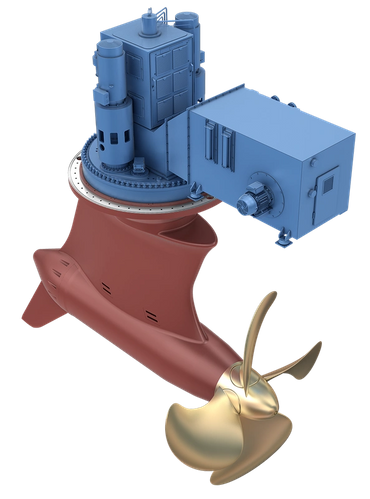

Rolls-Royce has launched a new range of smaller, more compact podded propulsion systems: the ELegance pods – one with an open propeller, the other ducted.

Per Nahnfeldt, General Manager Product – Electric Propulsion, Rolls-Royce, said, “For many years we have recognized the gap in the propulsion market for smaller pods, including ice-class, in the 1.5MW to 7MW power range. These new pods – based on our Permanent Magnet technology – complement our broad product portfolio and sit well with our range of frequency drives and electrical systems. We can now provide a complete fully electric propulsion package.”

The use of permanent magnet (PM) motors in podded propulsion provides a high motor efficiency over all speed ranges. Their use also results in a pod that optimizes the trade-off between electric, mechanical and hydrodynamic efficiency, the manufacturer said.

Andreas Seth, Rolls-Royce SVP Electrical, Automation & Control – Marine, said, “Our PM technology and knowhow has become a game changer for many of our product innovations. In this case the PM technology and the motor fitting in the casing have allowed us to create a sleek, slimline pod, which adds significantly to hydrodynamic efficiency.”

Nahnfeldt added, “The pods feature a ‘twin tail’ concept to further improve efficiency while significantly reducing cavitation-induced noise and vibration. A new integrated hull fitting interface also allows a compact head-box to be used, which minimizes drag and further improves hull efficiency. This also allows the height and tilt of the pod to be adjusted, allowing operators to select the optimum propeller size for the vessel.”

The 1A Super and Polar Code 6 ice class pods have also been designed with installation and maintenance simplicity in mind. For example, should the pods need to be replaced they can be lifted and mounted in water. This builds on the experience from the underwater mounting of Rolls-Royce azimuthing propulsors and provides a means for replacement of the complete units, including the steering gear, for ease of maintenance and service in, as well as out of, drydock.

“Both pushing and pulling pods have been designed with several layers of redundancy on critical and hard-to-reach components, with service points positioned for easy access,” Nahnfeldt said.

Rolls-Royce noted that maintenance is optimized by way of fewer moving parts within the below-the-waterline housing and the only components that require dry-docking service are the pod’s bearings and seals. These however have a life expectancy of 10 years or more before they need replacing.

“This reduced maintenance requirement correlates directly to low life-cycle costs,” Nahnfeldt said, adding that with a focus on environmental safe operation, the robust sealing solution that has been selected has no oil-to-sea interfaces. Should system oil leak at all, it is fed into a dedicated sump connected to the ship’s bilge system.

Rolls-Royce is now building a 4.6MW ELegance pod at its Rauma facility in Finland and is in discussions with shipowners to install the pod in a pilot project.