ZUMWALT: Maritime Reporter's 'Great Ship' of 2013

It is the newest and most transformational warship ever built, and yet it has also had the longest gestation period. Whether you call it new or old, you have to call it different.

The pedigree for DDG 1000 is not from the Spruance or Arleigh Burke class of guided missile destroyers, but rather it comes from the SC-21 (Surface Combatant for the 21st century) concept from 1994. Like DDG 1000, SC-21 was not about anti-air warfare. It was all about strike. SC-21, along with the Maritime Fire Support Demonstrator (MFSD) “arsenal ship” concept, evolved into DD-21 (Destroyer for the 21st century), also known as the 21st century Land Attack Destroyer, and featured two long-range guns and 128 missile tubes.

Unlike the existing DDG-51 guided missile destroyers, DD-21 deemphasized the anti-air and anti-submarine capabilities, although it had some of each. It was about power projection and expeditionary support.

The large size was to accommodate the power projection features, including a big magazine to provide plenty of fire support to Marines on the beach. Other concepts being tested were the new hull form, electric drive and minimum manning. While the ship was bigger, the crew would be smaller. At some point a crew size of under a 100 (96 not counting the air detachment) was arbitrarily assigned. It was a stretch goal, but planners saw that there would be no “bench” to fill in for casualties; too few Sailors to stand watches, conduct preventive maintenance or hold sweepers on what was a huge ship. To support such a dramatic reduction, the ship would require a high degree of automation to support operation and the flexibility to allow the crew to operate from multiple stations.

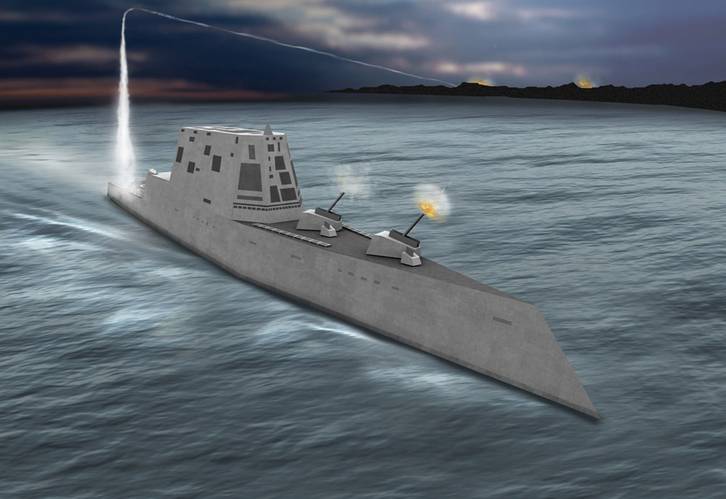

But in 2001 the DD-21 program was cancelled, although the development work transitioned to DD(X), now known as DDG-1000 or the Zumwalt class. Throughout this gestation period the ship was envisioned with a tumblehome hull and a stealth design that more closely resembled the Civil War CSS Virginia (the ex-USS Merrimack) or one of the Great White Fleet capital ships that circled the globe in the early 1900s. Able to fire projectiles long distance with great accuracy, the ship was supposed to give the Marines the firepower they needed for expeditionary assault, and was more a replacement for the battleships than any other class of ship.

Some of the DD(X) technology was leveraged from existing programs. Tactical Tomahawk offered a programmable strike capability and could be launched from vertical launch system VLS cells common in the fleet.

The Navy’s version of the Advanced Gun System was based on an Army 6-inch (155 mm) self-propelled gun system called Crusader. The Army planned to buy 800 vehicles, so the Navy thought it was wise to leverage that development and come up with a naval version. But when the Army cancelled Crusader in 2002, the Navy was stuck with the full bill.

The United Defense (Now BAE Systems) AGS fired the long-range land attack projectile, a rocket-assisted round with GPS guidance and hoped for ranges of up to 100 miles.

The Navy looked at several different designs based on the number of VLS cells, guns and ammunition capacity. Eventually they settled on two guns with 600 rounds total, and 80 VLS cells, in a 14,800-ton ship. The 80 Raytheon MK 57 peripheral vertical launch system (PVLS) cells were installed between a double hull for survivability, and are capable of launching just about every naval missile fired from surface ships.

Most of the truly transformational technology envisioned from the beginning eventually was incorporated in DDG-1000, a ship that is unlike anything else in the fleet. The ship had a composite deckhouse and helicopter hangar to reduce weight, and the “apertures” were embedded in the superstructure; there are no rotating antennas. Electric drive on warships isn’t new, but the integrated propulsion system is entirely new for the U.S. Navy, and provided significant flexibility to generate and use power as needed, including a significant reserve for future power-hungry energy weapons like lasers and electromagnetic railguns.

Significant automation and a new “autonomic” firefighting system allowed the ship to operate, fight fires and recover from damage with far fewer Sailors than ships in the fleet today.

Not so obvious to the observer is the enabling technology, the Raytheon total ship computing environment (TSCE), the key behind the ship’s significant automation and reduced manning, that connects every aspect of the ships’ operations with a central backbone that also enables modularity, so new or upgraded capability can be easily and seamlessly integrated without added systems or electronics.

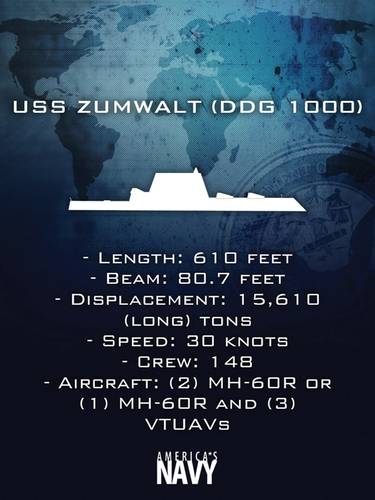

It’s a much larger ship compared to the Aegis destroyer or cruiser, wide at the waterline, a bulbous nose and no bridge wings. The gun barrels are stowed when not in use to further reduce the ship’s radar cross section. When underway, there’s no reason for anyone to be out on deck.

The DD(X) program called for 32 ships, then 24, then 12. Finally, the Navy said that analysis indicated that only seven were needed. Then Chief of Naval Operations Adm. Gary Roughead called for the program to be truncated with just two ships built, although Congress later reinstated the third ship.

Delivery to the Navy is scheduled for late next year. The formal christening ceremony originally scheduled for Oct. 19, 2013, had to be cancelled due to the government shutdown. It is now slated for spring of 2014.

Two more ships of the class are under construction at BIW, Michael Monsoor (DDG 1001) and Lyndon B. Johnson (DDG 1002).

As big as it is, it has the stealth characteristics to make it appear as a small fishing boat on an enemy’s radar scope. It is a stealthy giant.

“It’s a gigantic ship—14,800 tons—it’s an incredible machine,” said Vice Adm. Tom Copeman, commander of Naval Surface Forces. “Right now the plan is for them all to be home ported here in San Diego.”

Visiting the ship on Nov. 21, 2013, Defense Secretary Chuck Hagel said the Zumwalt-class destroyer “represents the cutting edge of our naval capabilities.”

Because the ship will be assigned to the Pacific Fleet, Hagel said it “represents an important shift … in America’s interests to the Asia-Pacific.”

Another new concept for DDG 1000:

The Raytheon EMEs

Electronic Modular Enclosures (EMEs) introduced an innovation to shipbuilding, essentially preassembling hardware components prior to delivery to the shipyard. Sixteen of the ruggedized EMEs are installed onboard the new DDG 1000-class multi-mission destroyers.

According to Tom Moore, director and DDG 1000 deputy program manager with Raytheon Integrated Defense Systems, the Zumwalt’s mission systems equipment are mounted on racks and installed in the EMEs. “All of the assembly, integration and testing is done on our factory floor before delivery,” noted Moore. “The fully populated enclosures are installed onboard, in synch with ship construction phases, and it’s done. It saves mounting, cabling and integrating individual racks of equipment, hardwired to the ship.”

“Each of the ships’ 16 EMEs contain up to 235 COTS racks, which equates to 90% of the combat systems equipment. EMEs offer an affordable approach to combat system integration and testing,” said Moore.

Four sizes, from 18-35 feet in length, weighing up to 18 tons, the EMEs contain computing, radar, communications, sonar and sensor mission systems equipment. Additional benefits, EMEs also minimize the footprint occupied onboard the ship (size and weight) and maximize efficiencies in both power and cooling.

The EMEs were built with the space, weight and power margin to accept growth. The modules are shielded for electromagnetic interference (EMI) and have the power, cooling and open architecture standard interfaces for ease of maintenance and tech refresh. If a particular system needs to be upgraded, there’s no need to replace the entire module, but only gear in the particular rack.

The ease of upgrades is important in order to capitalize on technology advancements as subsequent generations of COTS equipment and systems should be faster and smaller. “If and when the ship takes on new missions, more systems, capabilities or programs will need to fit on the ship from an integration standpoint,” Marcley said.

Swapping out or changing a rack is simple. “Most equipment in the racks is the size of a box or small suitcase,” said Moore.

To date, Raytheon has delivered 35 fully populated, integrated and tested Electronic Modular Enclosures, completing deliveries for the first two ship sets (DDG 1000 and DDG 1001) as well as an additional three EMEs for the Self-Defense Test Ship.

New radar helps DDG 1000 face the future

According to Wade Knudson, Raytheon’s DDG 1000 Program Manager, Zumwalt has an entirely new radar, the Raytheon SPY-3, installed in three faces and embedded in the superstructure.

The Zumwalt’s AN/SPY-3 is an active electronically scanned array (AESA) X-band multifunction radar. The ship was originally going to be equipped with a dual band radar with both the SPY-3 and a volume search radar, an installation also found aboard USS Gerald Ford (CVN 78). But according to Knudson, the SPY-3 software has been modified.

“We created additional software code for the SPY-3 to add the volume search capability for DDG 1000,” said Knudson.

Because they can’t radiate the radar yet, the SPY-3 radar will be taken to the Wallops Island test facility to operate in the maritime environment. “We’ll be flying aircraft and missile targets at the radar to evaluate the performance. Then we’ll take the radar to the self-defense test ship at Naval Surface Warfare Center Port Hueneme for more testing,” Knudson said.

The ex-USS Paul F. Foster is used to test sensors and defensive systems against actual targets fired toward the ship, which is operated remotely with nobody on board for such testing. “We’ll mount the radar on the SDTS at the same height as on Zumwalt, and conduct about 20 test firings.

Highly Automated Combat Capability

The highly automated system, which relies on commercial off the shelf (COTS) computers, is designed for reduced manpower for both operations and maintenance. For anti-submarine warfare, the ship has both a Raytheon medium frequency sonar for ASW and a Lockheed martin high-frequency sonar (the same as used on U.S. submarines) for in stride mine avoidance, as well as a towed array.

The total ships computing environment (TSCE) is the brain, spinal cord and central nervous system. It controls engines and motors, valves, pumps, fuel, firefighting and damage control systems. Cameras can show the crew what’s going on everywhere on the ship, especially in the unmanned spaces, and sensors can detect fires and secure power and energize the water mist system.

The assembled modular sections were joined together and outfitted in BIW’s Ultra Hall—super units became mega units and then ultra-units. After the sections are joined together the ship is taken outside to the Land-Level Transfer Facility (LLTF); where masts, weapons and the A/N SQQ-89A(V)15 are installed. The ship then moves aboard a barge that can be ballasted down to float the ship.

Our equipment has been delivered for the first two ships,” said Tom Moore, Raytheon’s DDG 1000 deputy program manager. “Now that Zumwalt is in the water we’re getting equipment integrated and powered up on the ship.” Knudsen said the ship can quickly be configured for different missions, such as setting flight quarters, opening the hangar doors, activating antennas. “It’s all automated with preselected functions,” he said. “When the ship goes to general quarters, the TSCE starts setting “condition Zebra,” securing valves and hatches, even shower drains, and indicates any hatches being opened.”

The ship mission center (SMC) is the hub for shipboard operations. The computerized functions rely on lots of software. “We’re delivered more than 6.7 million lines of code already,” said Knudsen.

“She’s coming together well,” said Moore. “Ship two is ready to go, right behind it.”

“Producibility” was a design goal for the Navy and the shipbuilder. A three-dimensional design tool was used in production planning, allowing designers to try different options to fit pieces together before deciding upon the final arrangement and process works. The first DDG 1000 was “virtually built” numerous times in CAD to validate the process before the first piece of metal was cut.

While the Zumwalt-class is radically different from the Arleigh Burke DDGs, they do share some basic commonality with things like valves and pumps. The Zumwalt was designed to have 30% fewer parts overall, and many of those parts are common with DDG-51–63% parts commonality, according to navy officials.

Captain Kirk

“Once you are in her presence, you see how beautiful and sleek she is,” said Capt. James Kirk (pictured), the prospective commanding officer of Zumwalt. “I was surprised when I stood on the bow forward of the guns and was taken aback by the size of the superstructure,” Kirk said. “She is imposing.”

“She can operate close inshore, independently for an extended period, or with a Joint Strike Group. She’s a multi-mission ship optimized for the littoral, and with an emphasis on land attack and strike,” Kirk said.

DDG 1000’s long-range gun and 80 MK 57 vertical launch tubes can deliver an arsenal of weapons to strike targets ashore, afloat or in the air.

According to Kirk, her designers had two important goals: increase survivability and decrease her manning. “Despite her size, she has reduced signatures to lower her vulnerability to detection, which is important in the littorals. She’s about 1.5 times larger than an Arleigh Burke guided missile destroyer, yet has half the number of Sailors because her technology and automation is vastly superior.” The bridge is designed for three watchstanders, and there are only two people on watch in engineering at any given time.

Kirk said the power margin and total ship computing environment (TSCE) will enable the ship to keep the combat systems relevant and support future capabilities. With TSCE and IPS, everything is connected. The crew can establish doctrine statements for operational decisions, so the system knows exactly how much power is required for any situation.

Kirk says he has frequent interaction with the Superintendent of Shipbuilding at Bath, the Program Executive Officer Ships and the DDG 1000 program manager, the Naval Surface Warfare Centers, and industry representatives from Raytheon, General Dynamics, BAE Systems, Huntington Ingalls, Lockheed Martin and others. “It takes a village,” Kirk said.

“We’ve all worked to generate a shared understanding,” Kirk said. “I’m trying to be a good listener.” Kirk said the crew is coming together. “We have 41 here at Bath now, and another 40 at the detachments in San Diego and Norfolk undergoing their precom training. They are a marvelous group of dedicated young men and women.” We have two objectives, to ready the ship for combat operations, and honor our namesake,” Kirk said. “We couldn’t be prouder to associate ourselves with the name Zumwalt.”

Zumwalt is a “Destroyer on Steroids”

The ship is named for former Chief of Naval Operations Adm. Elmo R. “Bud” Zumwalt Jr., who served as CNO from 1970-1974. His son, James Zumwalt, said the ship means a great deal to him and his family.

“It continues our father’s legacy. While CNO, my father pushed for changes 43 years ago, some of which are reflected in the DDG-1000. His push for improving life for his sailors is reflected on DDG-1000 by its four-man staterooms for enlisted personnel. His push for multi-purpose ships is reflected in DDG-1000’s numerous capabilities,” Zumwalt said.

While his father served on “tin cans,” including USS Dewey (DLG 14), which he commissioned at Bath in 1959, he said the new Zumwalt is much more. “Calling DDG-1000 a destroyer is comparable to calling a rotweiller a yorkie. With the capability of providing far more accurate naval gunfire support (NGFS) at distances almost five times greater than our retired battleships, DDG-1000 has much more bite than the biggest NGFS ships ever built. The stealth technology provides DDG-1000 with the appearance of a yorkie but equips it with the fight of a rotweiller. As a life-long destroyerman, however, I think my father would keep to tradition, perhaps characterizing it as a ‘destroyer on steroids.’”

“USS Zumwalt is the Navy’s battlewagon of the 21st century,” Zumwalt said.

“There is a lot of coincidence between the ship and its namesake,” said Zumwalt. DDG-1000 will transform the Navy on a level not seen since my father’s tenure as CNO. He is credited with eliminating more U.S. Navy ships from the active rolls than the Japanese were able to eliminate during World War II. Doing so reduced the Navy’s funding for maintenance while providing the funding for research and development to build a modern era of warships.”

“Also like my father, DDG-1000 proved to be very controversial. Most of what I have read about my father by Navy historians and researchers praise him for his visionary leadership, although he had his share of critics while he served in office,” said Zumwalt. “He often said, however, that he knew his changes on many fronts had earned him a long list of friends and a long list of enemies—and that he was equally proud of both!”

Saint Elmo is the patron saint of mariners. “My father was known as the ‘Sailors’ Admiral.’ I believe when the USS Zumwalt takes to sea, there will be two Saint Elmos watching over her and her crew.”

(As published in the December 2013 edition of Maritime Reporter & Engineering News - www.marinelink.com)