Fugitive Emissions: The New Regulatory Elephant in the Room

W&O Supply and Chesterton team up to reduce harmful emissions out in front to the EPA’s monitoring program. It’s less expensive than you might think.

From the UK’s Maritime and Coastguard Agency comes the September 2014 news of a barge operator fined for releasing dangerous gas into the atmosphere. The UK-based firm was made to pay almost £111,000 in fines and costs as a result of emitting unsafe levels of a gas; in this case, hydrogen sulphide (H2S). And, while an investigation by the MCA showed a number of health and safety failings by the operator, the bottom line was that not enough was done to stop the offending vapors from escaping into the atmosphere.

On this side of the pond, that sort of oversight has been going on for decades in the nation’s industrial facilities, refineries and waterfront storage terminals. And now, it is coming to the water itself. That’s because the U.S. Environmental Protection Agency (EPA) may be ramping up to monitor what is characterized as “fugitive emissions” from barges and other marine vessels. The Clean Air Act, which was first put in action in the 1970s and then revitalized in the 1990s, is now affecting industries it has never affected before – one of these being inland waterways.

It works something like this: The EPA maintains a list of various chemicals for which they monitor varying levels of leakage into the atmosphere. As barges carry chemicals up and down the Mississippi River, the EPA might utilize aerial coverage to detect fugitive emissions from these vessels. Regulations can also vary based upon a ships’ location and state-level Clean Air Act laws. Clearly, the rules can be difficult for owners and operators to understand and comply with.

According to David Lamphier, Manager of Sealing Technologies, at W&O Supply, the EPA is employing two primary methods of monitoring and enforcement. “One is to fly overhead in helicopters that take infrared readings from the air of these barges as they travel down the river,” he explained to MarineNews in October. He added, “The other is to be boarded and sniffed with detection equipment that registers parts per million emissions. Some companies haven’t seen it at all – some have – but the monitoring has definitely begun.” According to Lamphier, no fines have yet been levied, but the prospect for that to happen with the accelerated regulatory oversight is very real. As a direct result, many owners have reached out to W&O and Chesterton in an effort to better understand and, more importantly, comply with EPA rules.

EPA documents have shown that airborne remote sensing survey data acquired with passive gas imaging equipment (PGIE), also known as infrared cameras, have shown potentially significant fugitive volatile organic carbon (VOC) emissions from petrochemical transport barges. And, according to the University of Toledo’s College of Engineering, “fugitive missions” are defined as those that are not released through a stack, vent, duct pipes or other confined air stream are termed as fugitive sources.

In 2008, an EPA aerial survey detected leaks from 45 different barges located in the Mississippi River and the Intracoastal Waterway over a five day period. The ground-based monitoring detected leaks from over 18 different barges in the Port Allen lock during the study. Hence, the issue is one that EPA is watching. For tank barge operators, it may be an issue worth getting out in front of. One way to do that may be found in a reasonably priced equipment change.

Chesterton & W&O Team Up to Address Fugitive Emissions

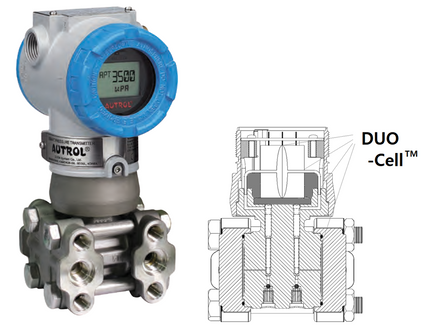

As the issue becomes more prevalent, W&O and Chesterton have teamed up to provide a turnkey solution for operators, one that marries Chesterton seals and valve packing with various brands of OEM valves that can be installed onto tank barges. The firms also recently held an educational seminar centering on total sealing solutions for pumps and valves to help customers maintain compliance with EPA regulations. The valve packing solution, for example, is a low emissions packing design, which will keep equipment outside the vent system in compliance with EPA regulations for a 5-year period. According to W&O, it has passed the API industry test for low emissions packing and is approved by the likes of Exxon, Chevron, DuPont, Marathon and others.

Vance St. Jean, a Senior Manager at Chesterton, told MarineNews in October, “The release of fugitive emissions is a big problem today. The EPA is driving this emissions monitoring program. They’ve actually been doing it since 1990 with the passage of the clean air act. Since then, there have been lower and lower leak rates that have been obtainable, and this law addresses all aspects of industry – manufacturing, production, transportation of volatile organic compounds or VOC’s. Businesses are signing agreements with the EPA to keep their emissions down. What we’re seeing is that the EPA will demand 100ppm leakage rates or less for valves that are in these processes.” St. Jean went to explain that customers – marine operators, for example – were starting to be proactive in using technology that will get them to that 100 ppm level, and below. Hence, what W&O and Chesterton are now offering to barge outfits, has been around a long time, but primarily targeted towards refineries and other similar operations.

W&O’s David Lamphier added, “The majority of customers we’re dealing with right now are delivering to the refineries. Those refineries are being held to these requirements. So the barge companies are being proactive here and telling their customers – we’re taking care of it, as well. This involves leaks on decks too – not just talking about emissions, but pipeline leakage as well.”

The W&O/Chesterton Turnkey Solution

In a newbuild scenario, W&O would provide valves from their existing stocks – any number of OEM brands – and marry that with the Chesterton packing to provide a total engineered solution. The procedure involves installation of a spring mechanism that constantly maintains load on the packing, which also reduces the amount of labor involved with the continual on board task of packing adjustments.

For a retrofit job, the work is either done dockside or in drydock. The barge doesn’t have to be pulled out of the water. Because the work does not involve tank entry, no safety entry permits are required and everything is done topside. Typically, says Lamphier, a complete barge refit can be accomplished in two days and for around $6,000 in labor and materials for the average 30,000 barrel barge. As MarineNews was going to press, a large Midwest barge operator already had two barges fitted with the equipment, with tentative plans for as many as 50 more, depending on the results achieved from the initial units.

Chesterton 1622 Emissions Packing is designed to minimize valve emissions and exceeds current emission requirements for the refinery, petrochemical, and chemical industries. The Packing provides for superior emissions and leakage control under harsh process conditions. This construction results in a non-hardening, flexible packing that will not shrink or absorb moisture. The strands that make up the packing slide easily over one another in response to gland pressure, creating a secure and reliable seal.

Using American Petroleum Institute (API) and EPA testing guidelines, W&O and Chesterton report leakage levels that have been lowered to 12-13 ppm. Consequently, the packing materials – Chesterton 1622 packing, for example – are warranteed to not leak in excess of 100 ppm for a period of 5 years. On one hand, and although the conversions might add 50 percent to the cost of a valve just to change the packing, weighing that extra $350 against the average cost of responding to an on deck leak incident ($10,000 per event, according to one customer), can provide immediate payback. Indeed, W&O claims that the solution can produce lifetime savings of $7,000, and that the system can pay for itself in just one year.

Ideally, W&O wants to crack the new build market – one which could yield as many as 600 new units in the United States alone this year. And, the solution is even more cost-effective as an OEM newbuild installation. Vance St. Jean adds, “What we’re talking to our industrial customers about is what is called pre-consent decrees. Using this solution on board their barges, these people will be in the position, when the EPA knocks at their doors, of having already installed low-emission, warranteed products on new valves, retrofits, and, at the end of the day, avoiding potential fines.”

Beyond Compliance

Beyond the obvious environmental benefits that customers can enjoy, the use of this equipment can, says St. Jean, be leveraged to potential charterers as just another example of a “safe and green” operating culture for the barge operator. And, a better sealed barge is just one more way for barge operators – who have already reduced their incidents of oil spills by more the 95 percent since the 1970’s – to show the environmental lobby that they are more than serious about their social responsibilities.

From the perspective of W&O, the Chesterton packing package is also just one more way to show potential clients that the firm is more than just a distributor of equipment. But, then this engineered solutions company has been marrying the right technologies and products to form turnkey solutions, working closely with OEM’s and end-user customers, more many years. Arguably, the control of ‘fugitive emissions’ is a great way to continue on with that tradition.

(As published in the November 2014 edition of Marine News - http://magazines.marinelink.com/Magazines/MaritimeNews)