APR Labs Greener Method of Propulsion

In 2006, Aries Propulsion Research Labs (APR Labs) introduced a new method of propulsion technology labeled Omni-Directional Propulsion (ODP). The method was created by designer Chris B. Hewatt and was first published on the United States Patent and Trade Organization (USPTO) Web site as publication 20060230847. APR Labs says that this unique design has been gaining attention in the transportation industry, but could have its greatest impact on the marine industry because it creates movement without propellers. Removing the propellers from the water would result in a virtually noiseless technology eliminating considerable drag from the drivetrain while at the same time increasing efficiency. The concept is green in nature because it eliminates most of the drivetrain components in just about every vehicle seen in transportation today.

The design uses similar technology to what is used to make attitude adjustments in the space shuttle. The space shuttle uses Control Moment Gyros (CMG) torque to position itself, but the CMG has a very limited range of movement and creates no forward thrust. Maintaining forward thrust is impossible because the shuttle's CMGs are fixed throughout the hull. ODP allows the CMG to freely rotate 360 degrees around the body of its host vehicle in a constant motion. As the CMG rotates around the vehicle, a locking mechanism is engaged and disengaged at the same degree of rotation and torque is produced opposite that of the rotating CMG. When this happens, torque is transmitted down to the host vehicle and forward movement occurs.

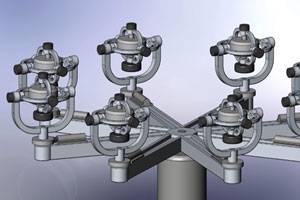

In 2009, APR Labs began testing ODP for efficiency and thrust using Computer-Aided Design (CAD). During testing, the single-shaft CMG design had problems with eccentric imbalancing that was solved by creating a two-shaft, four-shaft, and an eight-shaft design. To assist with design validation, APR Labs hired Prairie West LLC in Boise, Idaho to test the model and to gauge potential efficiency and forces produced by ODP. Prairie West used a combination of Solidworks 3D CAD and Simulation software to test the design and to create detailed reports of potential forces produced.

(www.aprlabs.com)