ABC: Powering Up for the Next 100 Years

Belgian power maker celebrates 100-year anniversary and jumps into a higher power class with a new diesel engine

On the occasion of its centenary, a new engine type, the DL36, has being launched to meet the future emission directives of 2016. The new range combines a small environmental footprint with the ability to deliver more than 10,000 kW. ABC’s power range will thus more than double, opening up new markets and segments. At the same time ABC has experience with hybrid drives and alternative fuels, from vegetable oils through animal fats to natural and bio gas. Maritime Reporter & Engineering News takes a closer at ABC’s 100-history and future.

Nine Belgium industrialists met on October 26, 1912 in the office of Notary Public Fobe in Ghent for reason of founding an engine manufacturing plant. The investors embodied past and future. One of them represented the company ONGHENA, which manufatured gas engines of an older design. He decided to stop production of these engines in favor of the new revolutionary diesel engines of Rudolf Diesel. The new company started its work under the direction of the engine manufaturer Georg Carels, who was a good friend of Rudolf Diesel, as well the two investors Marcel and Richard Drory. The name of the new company: ANGLO BELGIAN COMPANY.

ABC started to produce diesel engines in the power range from six to 40 hp, as well as a two-cylinder marine engine delivering 45 hp. ABC was already demonstrating three different engine types (1E, 2EM and 2D) at the World’s Fair in Ghent on September 28, 1913.

Already before World War I, ABC started to export engines to Australia and Russia, and business begain fairly well for the company. New developments, including the DX engine series, and bigger power output were introduced and quickly found customers in both the marine business as well as in the stationary power segment. The 1970s were tumultuous times for the company, but ultimately it survived. It was then that one of the most important markets, the former Belgian Congo, was lost because of their war of independence and the new nation Zaire did not have the finances for new engine purchases. But at the same time ABC developed a complete new engine: the DZC-series, with the goal of selling 100 engines per year.

By the end of the 1970s, the collapse of the enterprise was imminent, as the company needed fresh investment. While a number of qualified investors existed, the infusion of capital came with the demand that the existing management leave. While there was substantial resistance, eventually the old management team was replaced with new management which came out of the Belgian fabricant Pauwels, the building contractor Batibo and the Belgian Shipbuilding Association.

Simultaneously, they changed the company name into Anglo Belgian Corporation, better known simply as ABC. Soon after this also a pro-government investment company, GIMV, participated and considerably increased the basic capital. The first experiences with the new DZC engine was not successful, requiring a new round of investment.

But a capital increase was rejected by investors, and they transferred their shares to the Luxembourger Family Holding OGEPAR, which to this day still own 90% of the shares, with the remaining 10% belong to ABC. Along with the new fresh capital Ogepar again exchanged the entire management, and today management is in the hands of the General Manager Tim Berckmoes.

The existing engine series have been reworked and further developed to dual-fuel engines, and today’s engine portfolio consist of the DX and DZ-series with a power band of 138 to 4,000 kW. The applications are separated into three segments: main drives for inland waterway ships, seagoing ships, tugboats as well as fishery boats. Onboard gensets are available in the power range from 128 to 3,562 kW. In addition to the marine business, on-shore stationary gensets and locomotive business rounds out the company’s main markets. It’s worthy to note that, for the time being, the biggest and strongest Diesel-Hydraulic-Locomotive in series production, the VOITH Maxima 40CC, is equipped with an ABC engine of type 16 DZC-1000-176 in V-configuration, with an output of 3,600 kW at 1,000 rpm.

Keeping it Simple

ABC engines were developed following the KIS (Keep It Simple) principle: a mechanical approach with a minimum number of components enabling quick and simple maintenance.

Thus, ABC forgoes electronic components on the DX and DZ- series, eschewing such items as electronic governors or monitoring systems. All types feature mechanical instruments, e.g. Woodward Governor and analog measuring devices. ABC’s own development department concentrates on: improved fuel consumption, oil consumption reduction, power increase, use of bio fuels and the fulfillment of the required international exhaust legislations for maritime applications. All engines hold certificates of the most important international classification societies, and genuine ABC parts and certified factory service is available in 59 countries with 76 service stations keep the engines running.

With the current DX and DZ range, ABC is offering solutions in the power range of 150-4,000 kW aimed primarily at the the marine coastal, fishing, dredging, patrol-ships, tugboats and inland transportation vessels market. The engines are used in combination with alternators to generate electricity in power plants up to 30 MW and in powering locomotives with the DZ-engines In-line or V-configuration.

Meet the new DL-series

“This is a completely new engine designed from the bottom up,” said Tim Berckmoes, GM, ABC, during a special press conference.

The new DL36 range expands ABC’s market to larger vessels such as ferries, coasters, offshore vessels, navy applications, dredgers, and large tugboats, vessels that will be particularly affected by new edicts in designated emission control areas (ECAs). The design enables shipowners to satisfy future, tougher emissions legislations without having to fit exhaust after-treatment plants. With the 6 and 8-cylinder In-Line DL36 (3.900 / 5,200 kW) and the soon to follow V-versions (up to 10,400 kW) the company will be able to supply all major shipyards with solutions for any type or size vessel. The DL36 range will also allow the company to be competitive in the 20-80 MW power plant range.

With a bore x stroke of 365 x 420 mm (displacement of 43.9 l per cylinder), the DL36 will be set to deliver 650 kW/cylinder at 750 rpm with a bmep of only 24 bar, ensuring that the traditional ABC reliability and robustness is maintained. This 650 kW/cylinder makes the new DL-engine the highest power output in its segment.

Introducing innovative technology such as Miller combustion process (earlier closure of the inlet valves causes expansion of the cylinder charge and a lower combustion temperature, which has beneficial effect on NOx emission level), EGR, two-stage turbo-charging of company KBB and a radically optimized common rail system (rail pressure of up to 2.000 bar), the engine’s emissions are designed to meet the IMO/Tier III requirements without the need for any additional cost intensive exhaust-gas after-treatment systems, e.g. catalysts, while maintaining competitive fuel and oil consumption. The company anticipates a specific fuel consumption rate of 180 g/kWh at 100% load. The high pressure common-rail and electronic control system has been developed in cooperation with company Heinzmann.

For those applications not requiring IMO/Tier III, a full mechanical version will remain available. In addition, the engine is designed to offer a high degree of fuel flexibility: it operates reliably on all kinds of marine fuels such as HFO, MDO, MGO, dual and bio-fuels. All these factors make the DL-series ideal for ships needing a clean yet efficient form of propulsion.,The 6- and 8-cylinder in-line engines will focus mainly on the marine market while the V-engines (12 and 16 cylinders) will penetrate also the large generator set application to be found in thermal power plants as the 16DV36 will produce over 10 MW.

With the design and development of this new engine family, ABC confirms the position as a major player on the medium speed engine market.

Components and Systems

The one-piece crankcase is made of nodular cast iron. Sidewalls with large crankcase doors allow easier access into the engine. The hanging bearing block are hydraulically and also transverse uptight. Thus, a very high torsional stiffness is ensured.

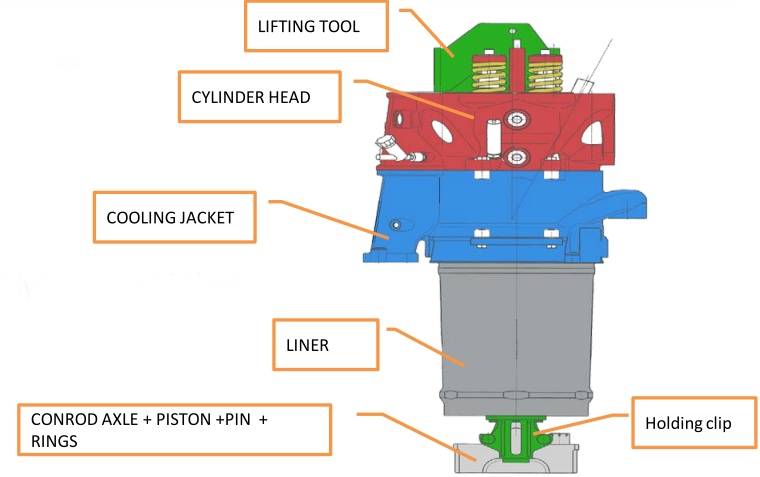

A special feature is the modular cylinder design unit, consisting of: cylinder head with four valves (two inlet and two outlet), cooling jacket, liner, conrod axle, piston, pin and rings. The complete unit is pre-assembled on a workbench, then mounted into the crankcase. Thus, the repair or assembly time can be substantially reduced. This is particularly advantageous in case of a necessary repair. According to ABC the 6-cylinder engine will be available for shipment in the second half of 2013 followed by the 8-cylinder in 2014. Further development steps are: develop-ment of the 12 and 16DV36 engine range and also the ex-isting DZ range will be developed to fulfill IMO III.

www.abcdiesel.be

(As published in the January 2013 edition of Maritime Reporter - www.marinelink.com)