Safe Transfer of Wind Farm Personnel

James Fisher and Sons plc announces the launch of two new exciting products to assist in the safe transfer of personnel during offshore wind farm operations.

• Vessel Motion Monitoring System (VMMS) provides accurate motion monitoring, improves safety during vessel transfer operations and offers impact load measurement combined with additional data logging capability

• Eco-Fender provides enhanced turbine transfer performance and safety

• High quality, in-house developed solutions using the proven technologies and capabilities of companies within James Fisher and Sons plc

• Developments that further underscore the commitment of James Fisher and Sons plc to the offshore wind sector

Fendercare Marine and Strainstall, members of James Fisher and Sons plc, in conjunction with Maritime International have launched two new products – the Eco-Fender range and the Vessel Motion Monitoring System, both specifically targeted to assist in the safe transfer of personnel during offshore wind farm operations.

Vessel Motion Monitoring System

Fendercare in conjunction with Strainstall, have developed the Vessel Motion Monitoring System (VMMS) to provide accurate motion monitoring during wind turbine transfer operations offshore. Vessel motion is the main safety factor when transferring personnel from shore to wind farm & turbines. An accurate motion monitoring system can increase the operational window considerably during critical operations by allowing the user to monitor all motion parameters rather than relying on significant wave height as the main limiting factor.

The VMMS can significantly improve safety levels during critical operations and can also be used as a dedicated health and safety tool, as it collects data for statistical purposes as well as accident investigations. When transporting personnel from shore to the work site (or between work sites) the motion trend displays can be used by the master to quantify vessel motions, enabling more effective changes in course and speed to be made to mitigate against seasickness. During docking operations and the offloading of personnel, the displays can be used to monitor heave levels and provide warning to the master when pre-set danger limits are about to be reached. All transfers can then be halted until conditions improve in order to safeguard personnel and avoid damage to vessels or equipment.

“The VMMS system marks a significant step forward in the development of our marine services business, demonstrating that we have the scale, technology, expertise and reach to deliver value added solutions to the offshore wind sector,” said Fendercare Business Development Director Martin Dronfield. “Moreover, it also exemplifies the unique and innovative approach of James Fisher and Sons based on over 165 years as a vessel owner and operator and leading provider of marine services worldwide”

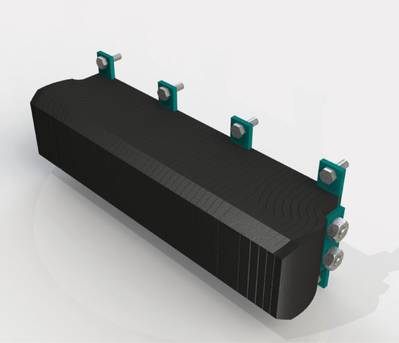

Eco-Fender

The new Eco Fender range has been designed with Maritime International specifically with one aim – to enhance the operational ability of wind farm access vessels. By substantially increasing the grip levels between the vessel bow fender and turbine fender tubes, the Eco-Fender™ promises to revolutionise crew transfer safety, allowing a much more stable and reliable platform to work from in extreme sea conditions, without having to make costly modifications to existing vessels.

All products within the Eco-Fender range are produced from recycled truck tyres, thereby reducing dependence on virgin rubber products, alleviating landfill and saving usage of oil.

Based on 60 years of experience with tugs, barges and workboats, the Eco-Fender range has been developed with the following criteria in mind:

• Significantly increased friction coefficient over existing materials and systems

• Economically competitive to existing systems

• Lighter than conventional extruded rubber bow fendering

• Increased durability over existing systems

• Quantifiable performance (energy absorption and reaction force)

The first products within the Eco-Fender range are currently being tested with vessel trials scheduled for late June 2012. The Vehicle Motion Monitoring System is immediately available with both products already experiencing a high level of demand.