Fleet Performance Management (FPM) can drive efficiency improvements of up to 38 percent, but many ship owners and operators are finding that FPM is costing, rather than saving them money. The expectation that once you plug and play an FPM system the savings will be immediate, has set a precedent that in real terms, is simply unachievable.

Peter Mantel, Managing Director of BMT SMART, a subsidiary of BMT Group, argues that FPM is a marathon, not a sprint and long-term collaboration is required to ensure a return on their investment. Mantel introduces the concept of a “Managed Fleet Performance” system, a turnkey approach which provides expertise in scoping and developing the business case, pre-survey, installation, training, data validation and analysis, and critically, integration of the technology into the various operational departments (change management). Mantel believes that these are all key ingredients to driving the efficiency improvements that owners and operators so desperately seek to secure.

The growth in fleet volumes at a time of global economic slowdown has resulted in excess supply and falling demand and as such, the profitability of many shipping companies is suffering. Although somewhat traditional and conservative, the shipping industry is waking up to the benefits of today’s digital world in helping to improve efficiencies. Owners and operators who are open to the opportunities that new technologies can deliver, stand to benefit the most and already we are seeing vessels being fitted with a wide range of sensors and monitoring equipment, with the aim of improving operational performance and reducing maintenance costs. This is where the ‘digital ship’ becomes part of the FPM equation.

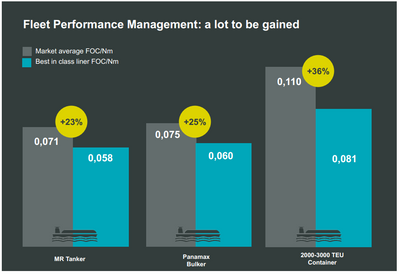

A recent study by DNV GL provided some high-level insights into the potential benefits that FPM can bring. Significant financial savings of up to £25 million for container fleets was highlighted, as well as substantial environmental gains (see Figure. 1). These figures clearly indicate that the rewards are substantial when FPM works efficiently but despite these many performance gains, FPM has not been able to fulfill ship owners’ expectations. The question is why?

On the surface, FPM seems a simple proposition but the reality is very different. Ship owners need the technical expertise and dedicated vendor support to ensure that it works for them. Furthermore, FPM relies on data from a wide range of sources including the weather and existing on-board data collection tools, as well as manual inputs from crew and onshore staff. Failure to capture all this data results in an incomplete picture. Additionally, all captured data then needs to be quantified, qualified and verified. This takes time and expertise that ship owners may not have and the FPM industry’s lack of transparency deprives those ship owners of the understanding they need.

FPM should also enable ship owners to identify trends however, disparate departments and traditional working processes can hinder the implementation of performance-enhancing recommendations. All of these factors add up to disappointing outcomes for many ship owners and operators. Significant gains can certainly be achieved but only with time, investment and collaboration across a number of stakeholders where the complexities of FPM are duly considered and managed effectively.

To maximize the potential savings that can be achieved with FPM, owners and operators need to understand the pitfalls to avoid and evaluate a range of critical considerations including:

- Objectives – what does success look like? What is your timeframe for success and what is your budget for investment?

- Current situation – what data do you have and what are you doing with it? What do you currently measure and what else could you be measuring? How do you apply learnings across the fleet?

- Fleet – what is the make-up of your fleet? Do you have sister vessels that you can apply learnings to? Do you have vessels that are on charter?

- Data – how will you collect data? How will it be aggregated? How is your data validated? How will you enhance and maintain your data’s value? How secure is your data?

- Hardware – what hardware will you need to collect data? Can it collect the data required to meet your objectives? Is it compatible with other systems and how will you maintain it?

- Insight – how will you turn your data into insight? How will you apply these insights to your fleet and how will you action these insights?

- Behavioral changes – how will you turn insights into actionable changes? How will you predict changes affecting planned maintenance? How will you make change happen?

- Management – who will manage your FPM? How will this impact their day-to-day activity? Do you have the internal expertise you need? How do you take advantage of the latest thinking?

The inherent complexities of FPM mean that there is currently no traditional product that has the capabilities to deliver fleet-wide actionable insights. As the capabilities and sophistication of FPM continues to grow, so too does the complexities and ship owners and operators are quickly recognizing that increasing in-house skills is becoming prohibitively expensive and time consuming. By taking a managed service approach to FPM, BMT can ensure agreed outcomes for its customers at a fixed cost. One such customer taking advantage of this Managed Fleet Performance (MFP) approach is Oldendorff Carriers who recently announced a new agreement with us which has led to the roll out of fleet performance management technology onboard Oldendorff vessels. Based on our unique on board data collection system and bespoke shore based management solution SMARTFLEET, this collaboration is centered upon driving down the carbon footprint of each vessel and improving the overall efficiency of the fleet.

Christopher Fee, Projects Manager at Oldendorff Carriers, recently commented, “Oldendorff recognized the potential benefits of implementing fleet and vessel performance monitoring. The innovative solutions BMT SMART offer to the maritime industry bring together the traditional practice of good ship operating and the impressive power of big data analytics. This supports our quest to further improve the technical and operational efficiency of our modern fleet of eco-ships.

“The project we are running with BMT acts as a cornerstone of our Green Ship Programme and we are very proud of what we’ve achieved together. The fuel we save through utilizing SMARTFLEET in our daily operations not only reflects well on our bottom line, but most importantly, is a huge win for the environment, since less CO2 is emitted per voyage. We believe this truly reflects our commitment to continuously reducing our carbon footprint, and through such types of initiatives, actively supports Oldendorff’s sustainable shipping objectives.”

Alongside Oldendorff, BMT recently celebrated the 50th installation on board the bulk carrier, MV Lily Oldendorff. This is one of very few real-life programs being implemented which truly demonstrate a long-term commitment towards driving change in the way shipping operates. This is only been possible through the close collaboration with Oldendorff so that we can provide a turnkey data management solution that delivers their desired outcomes. Through this managed service agreement, Oldendorff can reap the benefits of FPM whilst still focusing their efforts on core activities.

MFP is about how you first introduce fleet-wide performance management and then deliver the outcomes required by the customer. From agreeing a goal with the customers’ board and designing reports via cost savings analysis, through to comparative vessel performance reporting, as well as optimizing the placement of sensors on board to give the best quality data - all is within the scope of MFP. This long-term collaboration is the only way for owners and operators to achieve the digital revolution and transform past performance management disappointments into real ongoing savings.

The Author

Peter Mantel is Managing Director of BMT SMART, a subsidiary of BMT Group.