Paving the Way for 3D Printing in Naval Shipbuilding

A U.S. shipbuilder’s piloting of new technologies is redefining the future of the naval engineering and shipbuilding industries.

Huntington Ingalls Industries’ (HII) Newport News Shipbuilding division, in collaboration with the U.S. Navy, has led the adoption of additive manufacturing of metal components for nuclear-powered warships as part of HII’s digital transformation.

This technological development will result in the first certified 3-D-printed metal part—a prototype piping assembly—being installed on the aircraft carrier USS Harry S. Truman (CVN 75) early next year. After its installation, the assembly will be tested on board the ship for one year.

“This is a watershed moment in our digital transformation, as well as a significant step forward in naval and marine engineering,” said Charles Southall, Newport News’ vice president of engineering and design. “We are committed to partnering with the Navy to ensure that collectively, we are investing in every opportunity to improve and advance the way we design and build great ships for the Navy.”

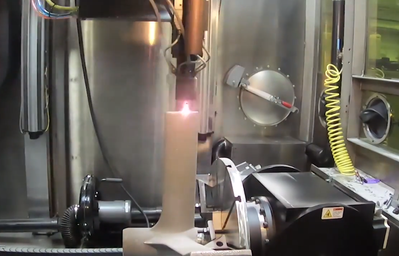

The additive manufacturing process recently approved by Naval Sea Systems Command (NAVSEA) is a highly digitized process that deposits metal powder, layer by layer, to create three-dimensional marine alloy parts that potentially replace castings or other fabricated parts, such as valves, housings and brackets.

The adoption of 3-D printing of metal parts is the culmination of years of work with Navy and industry partners that involved the rigorous printing of test parts and materials, extensive development of an engineered test program and publishing of the results, and could lead to cost savings and reduced production schedules for naval ships.

Earlier this year, Newport News announced a joint development agreement with 3D Systems that resulted in the installation of the ProX DMP 320 high-performance metal additive manufacturing system at the facility.

“We have delved into uncharted territory to create a positive disruption in our industry in much the same way the modern welding processes supplanted rivets, revolutionizing the way ships are built,” Southall said. “We’re proud to be leading the way.”