Multiple amphibious, multifunction dredges from Mud Cat are operating in Iraq to clean various dams and barrages that are positioned along the Tigris and Euphrates Rivers. Iraq’s Ministry of Water Resources (MWR) purchased the MFDs to remove accumulated silt, sand and vegetation at each dam’s basin. By performing regular dam maintenance, Iraq’s MWR can maintain the designed water levels at the dams to prevent structural components from being compromised.

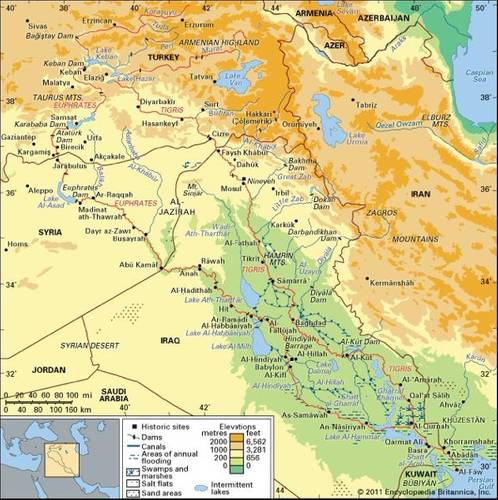

Originating in eastern Turkey, the Tigris River measures approximately 1,150 miles long through Iraq and flows in a southeasterly direction. The Euphrates River is approximately 1,700 miles long and also originates in Turkey, flowing southeast across Syria and then through Iraq. The upper Euphrates is quite shallow, allowing only shallow-draft boats to navigate the waters.

The two rivers have a confluence near Al Qurna to form the Shatt al-Arab waterway in southern Iraq, which empties into the Persian Gulf. In this area, an extensive marshland environment is present, making it difficult at times to navigate when water levels are low.

The Tigris and Euphrates Rivers are heavily dammed to provide water for irrigating in the semi-desert regions bordering the river valleys as well as creating a source for hydroelectric power. Damming has also been important for averting floods in Iraq, to which the Tigris River has been historically prone following the snowmelt in the Turkish mountains around April.

The Mud Cat MFD-1000 is an amphibious, multifunction, self-launching, versatile dredging machine that is one-truck transportable and can easily operate in many different environmental clean-up projects. It is capable of moving and dredging through shallow water areas where other single purpose dredging machines cannot operate.

According to the manufacturer, the MFD-1000 is designed for maximum productivity. It comes furnished with a single-piece hull built to ABS River Rules, a modern and comfortable cabin, easy-to-use joystick controls, a heavy-duty industrial excavator arm, and an up-to-date diesel engine.

The MFD-1000 is capable of walking from shore to bodies of water without the need for cables, winches, or cranes, reducing additional expenses for mobilization. Two pivoting rear steel spuds and a heavy-duty excavator arm maneuver the amphibious dredge on dry ground with ease.

While in operation, two front round stabilizers made of steel help support the dredge when it excavates up to 19.5 feet with a 180º swing. The two front stabilizers have a maximum depth of 12 feet and the two rear pivoting spuds have a maximum depth of about 17 feet. Two steel side tanks mounted to the hull provide additional buoyancy and stability when in operation. The MFD-1000 is also a self-propelled dredge with a single 24-inch hydraulic multidirectional prop-drive system, making it very maneuverable in the water system.

Mud Cat engineers included the industrial heavy-duty excavator arm in the MFD-1000 design so that it can attach to multiple interchangeable tools, such as an excavator bucket, an articulating clamshell bucket, a weed rake, a pile driver and a submersible cutter suction hydraulic pump, making the dredge more versatile for various light-duty and heavy-duty projects. Quick-release hydraulic couplings on the excavator arm allow operators to quickly change the tools without losing valuable operating time. Ali Ahmed Al Mayahi, Director of MWR Dredging Works, states the “ease of changing the attachments on the excavator arm is excellent.”

Liquid Waste Technology, which makes the Mud Cat dredge line, selected a Caterpillar 300 HP C.9 Tier 3, turbocharged and intercooled diesel engine and an 8-inch submersible cutter suction pump attachment to help meet MWR’s pump production requirement. The hydraulic cutter suction pump, designed at 3,600 GPM at 75 feet TDH, handles up to 3-inch solids and is capable of pumping over 1,650 feet in a 10-inch pipeline. One of the best benefits of Mud Cat’s cutter head attachment is the ability to dredge in a multidirectional method unlike the traditional one-direction dredging method. By using this new method, pumping production is increased. MWR’s Mr. Mayahi states MWR has been pleased with the overall pump production, which is near a “75 percent efficiency rating.” The MFD 1000’s one cubic yard excavator bucket and a 7-tine weed rake perform mechanical excavation efforts and vegetation removal, respectively.

Mud Cat’s MFD-1000 amphibious, multifunction dredges have already made a great impact on reducing the accumulated river sediment in these centuries-old rivers.

The MFD-1000 is also an excellent dredge to use in hydroelectric dams since sediments can disrupt the flow towards the turbines, resulting in decreased energy production and increased maintenance costs. By performing routine maintenance dredging, water storage volume can be increased while improving water clarity within the hydroelectric dam reservoir. Ultimately, dredging with the right equipment can keep production up and costs down.