Just six years after its introduction, MAN Diesel & Turbo has confirmed an order for the 1,500th G-type engine. Greek ship operator, Almi Tankers, will take delivery of the ultra-long-stroke 7G80ME-C9 type as prime movers for the two 317,000-dwt VLCC to be built by HHI (Hyundai Heavy Industries Group) in Korea. Coincidentally, Almi Tankers also placed the order for the very first Gtype engine. The crude carriers are due for delivery in, respectively, February and April, 2018. In both instances, the engine is Tier III-compatible.

Ole Grøne, Senior Vice President – Two-Stroke Promotion & Sales, MAN Diesel & Turbo, said: “The success of our ultra-long-stroke portfolio is a fantastic story for us. That we have already clinched orders for 1500 G-type engines since the G-type’s launch just a few short years ago is remarkable; the G-type is easily the fastest selling engine we have ever had.”

The new order resembles the order that Almi placed in 2012 when it ordered two 7G80MEC9 units for another two VLCCs. HHI reported that the engine, at that time the world’s first MAN B&W 7G80MEC9 unit, passed its official shop test in January 2013.

The G-series of engines, together with the established S-series of engines, constitutes MAN Diesel & Turbo’s modern, two-stroke engine program and cover similar power ranges in different rpm brackets. Both series are constantly maintained and upgraded to cater for the needs of both hull-lineoptimised vessels and propeller-rpm-optimized vessels.

Rationale behind G-type introduction

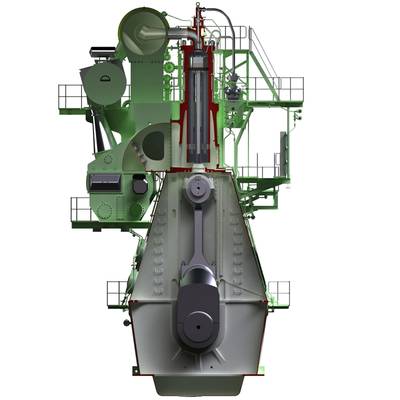

MAN Diesel & Turbo’s G-type programme entered the market in October 2010. The ‘G’ prefix before an engine means it has a design that follows the principles of the large-bore, Mark 9 engine series that MAN Diesel & Turbo introduced in 2006 with an ultra-long stroke that reduces engine speed, thereby paving the way for ship designs with unprecedented high-efficiency.

Following efficiency optimization trends in the market, MAN Diesel & Turbo thoroughly evaluated the possibility of using even larger propellers and thereby engines with even lower speeds for the propulsion of tankers and bulk carriers.

Such vessels may be more compatible with propellers with larger diameters than designs so far used, and therefore able to facilitate higher efficiencies following adaptation of the aft-hull design to accommodate a larger propeller. It is estimated that such updated aft-ship designs with the G-series of engines offer potential fuel-consumption savings of some 4-7%, with a similar reduction in CO2 emissions.

Simultaneously, the engine itself can achieve a high thermal efficiency using the latest engine process parameters and design features.