NOFIRNO Gasket Withstand Heavy-duty Fire Test

Manholes onboard ships or in industrial or offshore plants are generally only used from time to time. The manholes are closed most of the time and are only opened when there is a need for maintenance or other activities to be performed on the installation. Gaskets are used to ensure the steel sealing plates reliably seal off the manhole. The NOFIRNO gaskets supplied by Beele Engineering for these types of systems were recently subjected to one of the most severe fire tests possible.

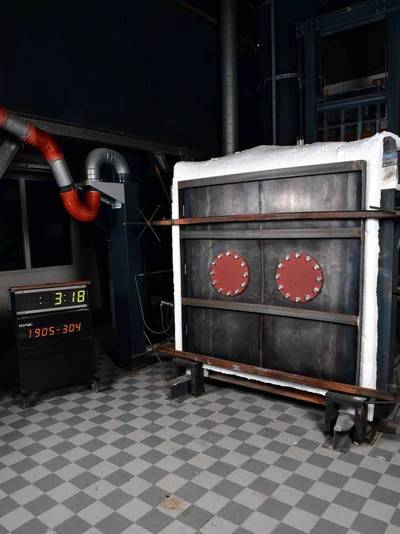

The fire test was carried out for two manholes in a non-insulated bulkhead sealed with 10-mm thick steel plates and NOFIRNO gaskets. The fire test was designed to investigate the fire-resistance of the gasket in accordance with the FTP Code 2010. The outside diameter of the gaskets is 365 mm, while the inside diameter is 275 mm. Openings for mounting the cover plate with bolts are located at 12 equally spaced places.

Although the cover plate and the bulkhead became red-hot during the fire test and furthermore deformed due to the heat, the 5 mm thick gasket continued to fully perform its function. As such, the gasket complies with the FTP Code 2010 and the fire rating was established at 60 minutes A-0.

The Beele Engineering NOFIRNO gaskets stand out due to their exceptional profile and high-quality rubber. Combined with BEBOLTITE bolts they ensure that with a low tightening force of 6 Nm a maximum seal of up to 6 - 15 bar is created. Once tightened, the gaskets provide a durable seal. That means that the regular tightening of bolts has become superfluous. Due to the NOFIRNO rubber's high restorative capacity, the gaskets can be reused after the flange has been unscrewed and then is tightened down again.