New Towage Dispatching Automation Tool Launched

Marine operations software developer Helm Operations and AIS services provider ShipTracks launched a new set of integrated features for harbor docking companies designed to streamline and automate the creation of towage orders directly from the AIS system.

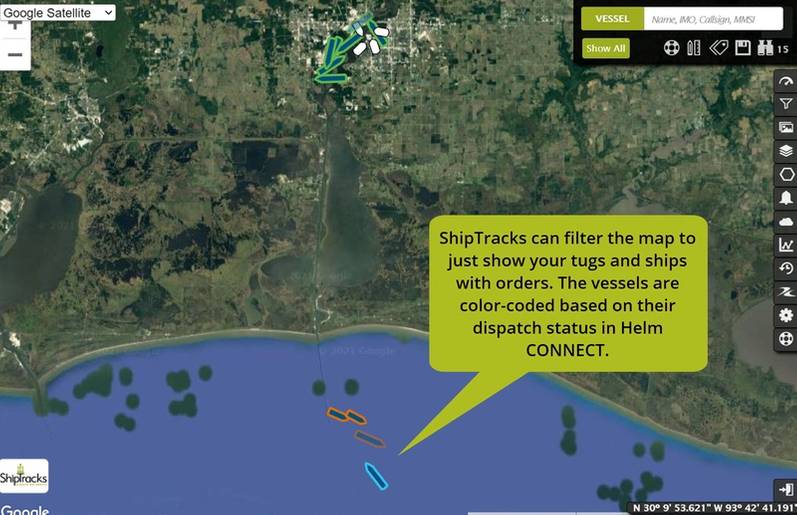

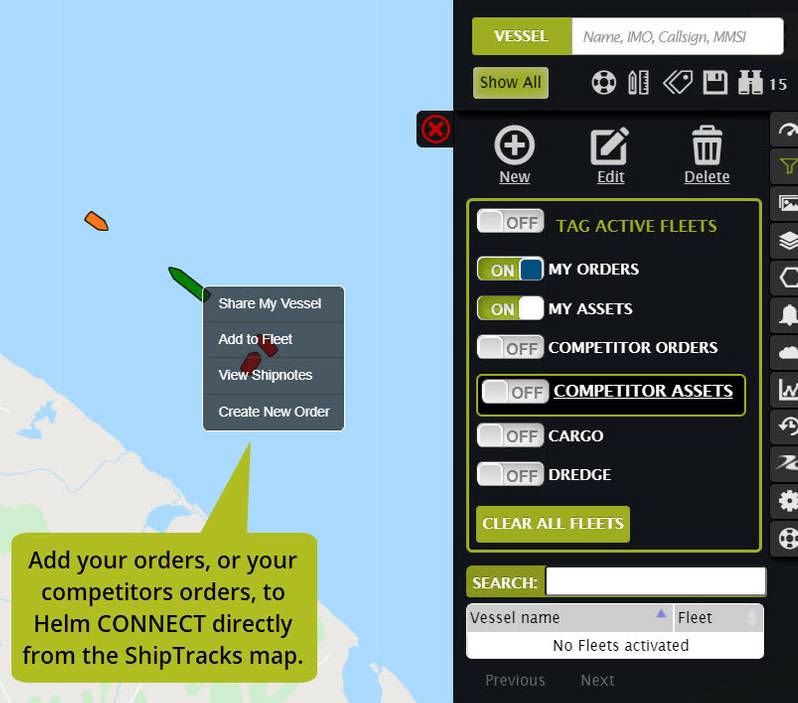

By linking Helm CONNECT Jobs dispatch software and ShipTracks’ AIS technology, operators are able to achieve greater operational awareness, reduced workloads for dispatchers and increased revenue as they identify and capture jobs that were previously lost to their competitors, the cmpanies said.

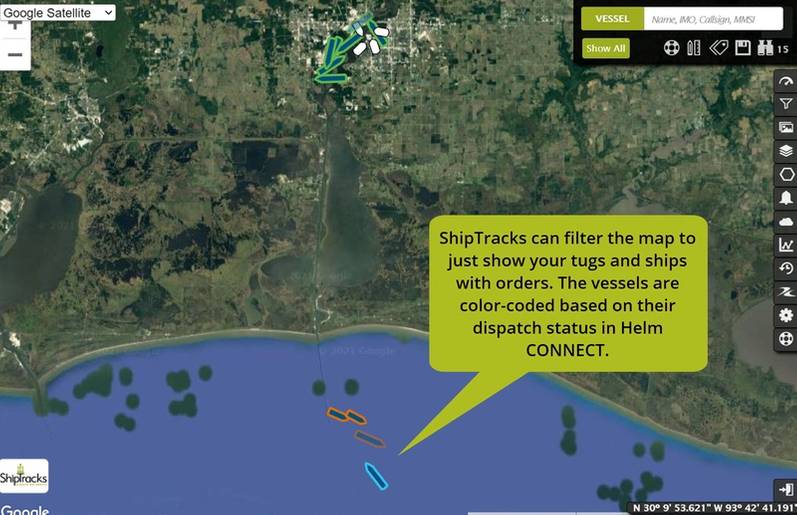

Modern harbor docking operations use a variety of tools to monitor their ports and ensure operational efficiency, including AIS systems to track vessel speed and movements, and tug dispatching and invoicing systems like Helm CONNECT Jobs to schedule and manage towage. Up until now, these systems have operated largely in isolation, but by integrating the systems, dispatchers can now not only receive automated notifications of vessels entering port, but also see immediately if their company has a contract with the vessel, if the towage work has been scheduled, and even automatically import the vessel and related jobs into the dispatch schedule—all from the AIS screen.

(Image: Helm Operations)

(Image: Helm Operations)

“When we traditionally look at AIS, what we’ve focused on is situational awareness,” said Charles Riley, CEO of ShipTracks. “But with this integration with Helm CONNECT we can now offer customers true "revenue awareness" and help them not only plan for safe operations, but also track and automate every potential job and source of revenue in the port to help them maximize returns and market share.

“By notifying companies when a vessel enters their region, displaying who the job belongs to and what its status is, then letting them enter orders directly into Helm CONNECT from the ShipTracks screen, we can make it so they never miss a job again."

(Image: Helm Operations)

(Image: Helm Operations)

Beyond just identifying new and potential revenue, the integration also provides operators with new tools to increase efficiency and reduce costs, the partners said. “On the commercial side, many companies still have staff who watch AIS screens throughout the day to identify when new ships are arriving in port. With this integration we can automate that,” said Paul Cyr, Senior Account & Integration Manager at Helm Operations and a 20-year veteran of the industry.

“On the dispatch side as well, we can automatically populate jobs for inbound vessels for review and approval by the dispatcher, reducing human error and saving hours of manual data entry. Even better, we can improve the dispatcher’s cost awareness by letting them know if tugs are moving without assigned work or if vessels are going too fast while mobilizing. This really makes it possible for dispatchers to reduce operational costs in port,” Cyr said.

(Image: Helm Operations)

(Image: Helm Operations)

John Buchanan, president of Harbor Docking and Towing, was an early user of the system, and said, "This integration has allowed us to automate our processes and improve data quality.”

“With ShipTracks, our dispatchers can create an order just by grabbing the vessel and dragging it to the order slot, prepopulating the form with vessel data provided by ShipTracks. What used to take them 5 or 10 minutes now only takes them 30 seconds and we know the information they're using is accurate. With margins getting narrower in the tug industry there is less room for error, so I would absolutely recommend this integration; you will realize efficiencies in your operations with it."

The partners said they are also exploring ways to more deeply integrate Helm CONNECT with ShipTracks’ AIS technology to improve vessel operations. “At Helm, we realize that through partnership with other innovators and market leaders, such as ShipTracks for AIS, we make operations simpler, faster, and more efficient for our users,” said Nolan Barclay, CEO of Helm Operations.

“Working with ShipTracks, we’re looking to make even more data available to operators within their AIS screen, including operational events like crew changes or planned maintenance, which affect the capability of the vessel. Beyond just harbor towage, we want to give operators of all kinds the ability to leverage this type of data in their planning to increase the efficiency of their operations, and we plan to announce more of these efforts throughout the year.”