New Monitoring System Boosts Safety of Reduced Iron Transport

NYK Line and MTI have filed a patent application for a technology that monitors the transport of reduced iron on bulk carriers.

Reduced iron is attracting attention because it does not require coke in the manufacturing process, a benefit for decarbonization of the industry.

The demand for transport by sea is expected to increase, but there is a need for appropriate cargo management on board ships to prevent overheating, fire, and explosion risks during transport, says NYK.

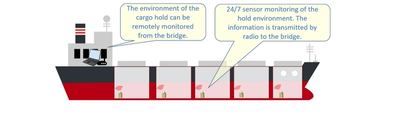

The system uses IoT technology to acquire and remotely monitor environmental data (temperature, humidity, oxygen and nitrogen concentration, etc.) in the holds in real time, thereby reducing the risk of cargo damage.

It also reduces the frequency of crew members’ visits to the holds to check on cargo and conditions, which is expected to prevent seafarer accidents such as falls and asphyxiation.

The environment in the hold during the voyage is estimated using machine learning and considers the ship's specifications, operational data, weather and sea conditions and initial cargo information.

The system can propose specific actions that should be taken such as ventilation, inert gas injection timing/amount and voyage route changes.

Using satellite communications, environmental data collected from sensors in the hold can be viewed in real time from shore. This enables safe ship operations and quality control throughout the entire ship and on land without relying solely on the crew's skill level, says NYK.

The technology has been patented separately by NYK, MTI, and NYK Bulk & Projects Carriers Ltd. (Patent Number JP7402386).