The "Near-Zero" Emission Tug

WorldWise Marine, a partner in the Offshore Ship Designers group, has launched a new design for a near-zero emission hydrogen powered tug. Michiel Wijsmuller, managing director of Offshore Ship Designers, said, "This new harbor tug will be able to remain on standby, and mobilize/demobilize with zero emissions, and will save up to 98 percent of SOx, NOx and particulate matter and 30 percent of CO2 emissions in total compared to a conventional harbour tug over the whole employment cycle. This is a major step forward for tug operators who have tugs operating in densely populated areas."

For the development of the Hydrogen Hybrid Harbor Tug, WorldWise Marine worked with Dutch tug operators Iskes from IJmuiden and Smit from Rotterdam, which are expected to build the first of the new tugs for use in European harbors.

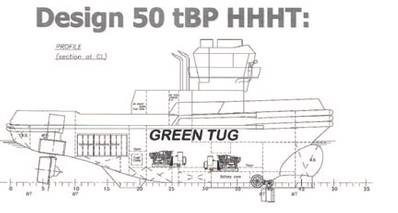

The 50 ton bollard pull tug is fitted with fuel cells and hydrogen tanks, where hydrogen is stored under a pressure of 430 bar.

The fuel cells, in combination with batteries, are able to provide sufficient power to operate the tug during standby and mobilization/demobilization periods. Only when substantial bollard pull is required to actually perform a berthing operation are the diesel generator sets used. Eighty-five percent of the time, the tug is powered by the fuel cells and achieves zero emission.

The Proton Exchange Membrane (PEM) fuel cells, developed by NedStack fuel cell Technology B.V. of the Netherlands, deliver well-to-propulsion efficiency of 34 percent, substantially better than the efficiency of conventional diesel direct drive installations. Further energy savings are made by incorporating power regenerating features by way of the towing winch when giving out and by one of the propeller units when the tug acts in the dynamic braking or steering mode.

Emissions in the diesel mode are reduced by installing 2-4 generator sets, so that the number of engines running can always be closely matched to the power demand, ensuring the engines always operate under optimal load conditions. That substantially cuts fuel consumption and also emissions, especially of particulate matter.

The HHHT is an azimuth stern drive tug with a single winch. It is fitted with a 300 kW inline Voith retractable bow propulsion unit to be used for mobilization and demobilisation purposes operating on electric/hydrogen power. When the tug switches to berthing/assisting mode and is running on diesel generators, the Voith unit is retracted, so cutting hull drag.

The HHT is 30.2 m loa, 9.5 m beam and has two main electric propulsion units delivering 1300 KW each. Four 650 kW Caterpillar C32 generator sets provide full power when needed to deliver the full 50-ton bollard pull.

(Reprinted from the August 2008 edition of MarineNews)