Minimize the Risks, Think Cold Bonding

Cold bonding: a safer alternative to hot work

Hot work required for welding, grinding and cutting operations presents certain potential hazards when conducted in potentially explosive and flammable environments. According to the Health and Safety Executive guidance 2013, “flammable liquids and vapors such as petrol, diesel, fuel oil, paints, solvents, glue, lacquer and cleaning agents are found in many places of work. If a welding torch or powered cutter is used on a tank or drum containing flammable material (solid, liquid or vapor), the tank or drum can explode violently.”

In order to minimize the risk, cold bonding solutions involving materials that are applied and cured at ambient temperatures can offer an alternative solution for repair and newbuild applications on metallic surfaces.

Welding in hazardous environments

Welding is proven to be the most recognized repair and fabrication method for metallic equipment and structures that joins pieces of metal by melting and fusing them together. However, in scenarios of flammable and explosive environments, the welding process is restricted, since sparks and hot metal can fly off in all directions and may drop down, creating hazardous situations. For example, if welding is to be carried out on containers or tanks, any flammable or combustible material within a 15-meter radius should be identified and controlled prior to the process. As described in the Defense Works Functional Standard Specification 031 for Internal Cleaning of Fuel Tanks, any hazardous material should be drained, cleaned, purged and tested for flammable vapors before the welding process starts. The transfer piping should also be drained, purged and blanked. Moreover, only trained welders should be involved in the process.

Assessment of the risks required before carrying out any hot work makes welding a highly time consuming process and therefore safer and time saving alternative options are becoming popular among the industry professionals.

Cold applied solution

Maintenance and construction welding requirements that would historically involve hot work can be completed with the use of polymeric cold bonding composites that are applied and cure at ambient temperatures. Belzona bonding was first used in the late 1950s to attach equipment ID tags and since then it has been widely used for repair and newbuild applications in a broad range of industries. As laboratory testing and field experience have shown, polymeric cold bonding composites can be applied for the repair of metallic equipment such as hoppers, tanks, flanges, support pads and pipe work, as well as for newbuild applications such as creation of load bearing shims, retention of bearing rings, modification of vessel internals and equipment assembly.

Over the years, Belzona materials were enhanced to resist higher pressures and temperatures as well as demonstrate high adhesion and compressive strength properties equivalent or greater than welding.

Put it to the test

In order to demonstrate the bonding strength, a tensile shear adhesion test has been conducted on two plates bonded on a deck, a 1.0m2 plate bonded using a Belzona adhesive material and an equivalent of 7mm weld along the edges of the plate. Determined in accordance with ASTM D1002, the results demonstrate that the bonded plate will be able to sustain up to 7,000kN in pure shear when the weld will only be able to support up to 2,000kN. This demonstrates that the bonded solution gives 3.5 times the shear resistance compared to the same plate welded round the edges with a 7mm weld bead.

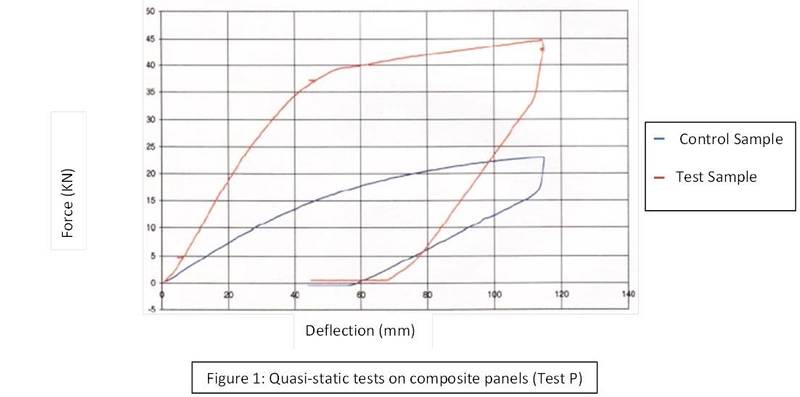

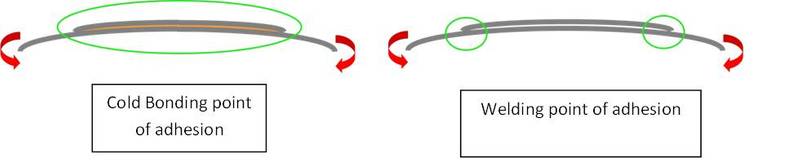

A quasi-static bending test was conducted to test the mechanical characteristics of the material. The two cold bonded plates did not immediately separate when bending forces were applied. Instead the composite spread out, the bending forces across the entire surface area, both plates and the bond uniformly distorted retaining the bond, demonstrating the retention of in-tact bond lines between both steel/adhesive interfaces.

The blue line in the graph represents the control steel plate (8 mm (5/16”) Thick steel) and the red line shows that the bonded composite plate demonstrates that plate bonding achieves greater load bearing strength (force axis) and greater energy retention (area under the curve) for the same ultimate deflection (deflection axis) proving the bond is not a weak link and actually enables the two bonded plates to deliver consistently and reliably twice the strength of the single control plate. The two bonded plates act as if they were indeed one plate twice as thick as the single plate.

Cleavage adhesion testing was carried out on Belzona 1111 (Super Metal), a paste grade epoxy material usually used for cold bonding applications, in accordance with ASTM D1062 at 20°C, 40°C and 60°Cin order to determine the effect of high ambient temperatures on bond strength. When fully cured, the cleavage adhesion of Belzona 1111 was found to be maintained across the 20–60°C test range, i.e. the bond strength was unaffected up to 60°C, and adhesion values were actually found to be slightly higher at higher test temperatures by virtue of the higher cure temperature. Cleavage adhesion values obtained were 1,330pli, 1,465pli and 1,450 pli, for 20°C, 40 °C and 60°Ctesting, respectively.

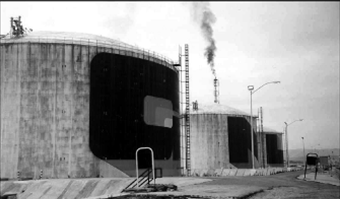

Refurbishment of three LNG tanks in Algeria

Based on the testing results, an Algerian Oil and Gas asset owner turned to Belzona cold bonding technology in order to refurbish three substantial Liquefied Natural Gas (LNG) tanks in 1990.

The LNG tanks commissioned in 1977 were severely corroded after 13 years of continuous service in a coastal environment in Algeria. Roofs and shells were extensively pitted due to on-going exposure to salt water and salty air moisture, resulting in severe gas leaks mainly on the roofs.

The client was looking for a reliable and long term solution to repair the LNG tanks taking into account all the safety considerations and without disturbing any parts of the inner tanks and their supports. Several solutions were considered for the repair including welding of new plates to the existing live tanks, welding new plates after purging the inner tanks and the insulation spaces, or fixing new patch plates over the roofs on site using cold repairs with epoxy adhesives. For safety reasons, the use of Belzona cold bonding system was chosen to avoid the welding requirements on site, as this was a major concern considering the thousands of cubic meters of highly flammable LNG in the tanks.

The main part of the project was to seal leaks in the outer skin of the tank and to bond doubler plates over the most corroded areas of steelwork. During the blasting process carried out using non-sparking grit to Swedish Standard SA 2, more live gas leaks were found on the surface of the tank and were directly sealed with Belzona 1291 (ES Metal), a rapid curing epoxy paste grade material.

Belzona 1121 (Super XL-Metal) with its extended working life, was used for bonding the reinforcing plates. Belzona 1111 (Super Metal) and Belzona 1321 (Ceramic S-Metal) were used in conjunction with Belzona Reinforcement Tape to repair and strengthen the nozzles through the tank roof.

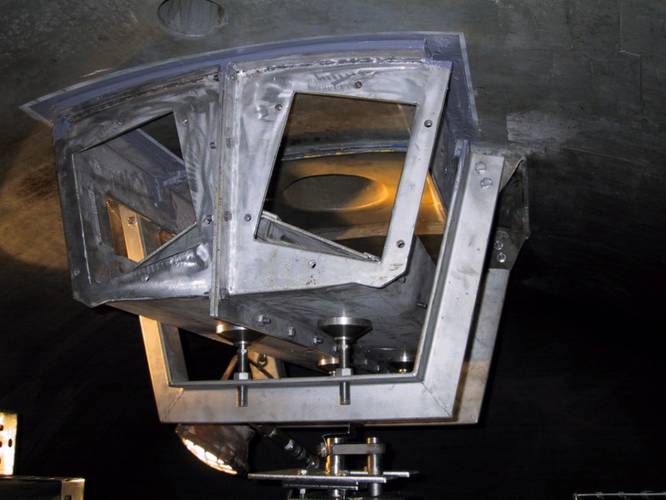

As the project proceeded, the ability to use Belzona materials as a structural adhesive was further investigated. Various tests both independent and at Belzona’s facilities were carried out on full size test rigs to confirm the suitability of Belzona to bond firstly the hand rail supports around the tank perimeter and finally the main vent pipe trunnion supporting several tons of pipe work. The project was carried out to very stringent standards with salt contamination, blasting profiles, climatic conditions and ultrasonic thickness measurements being constantly monitored. New furniture and platforms were installed on the roofs of the three LNG tanks where the different instruments were fixed to their original positions.

The Belzona solution was applied live to keep the site running with minimal disruption without hot work or use of mechanical equipment. No other alternative was deemed to provide a viable solution to the client’s requirements due to time scale and the risk of sparks. Since the application, it has been regularly inspected and has now been in service for more than ten years demonstrating the high efficiency of the cold bonding solution.

About the Authors

Anna Michael joined BelzonaPolymerics Ltd in 2014 and is a member of the PR team responsible for copyrighting and publishing. She is also responsible for the marketing strategy in the German speaking market. Anna holds a Bachelor of Arts in Communications and Media and a Bachelor of Arts in Language, Culture and Translation.

Alice Jucquois studied at the University of Lincoln, United Kingdom, and holds an MSc Degree in Marketing. Alice is part of BelzonaPolymerics Ltd Marketing Department, where she is responsible for the marketing strategy for the French speaking countries and development of brand awareness through PR activities.