MEGA MACHINES: Manson Prepares to Add “The Bionic Man” of Dredge Vessels

Manson Construction has long been a pillar of the U.S. maritime industry, rooted in a tradition of U.S.-built, U.S.-owned, and U.S.-operated vessels. The company was founded in 1905 by Peter Manson, when he dug up a jar of gold coins [because he didn’t trust the banks] and purchased a winch, a winch that was then put on a barge and that became Manson's first pile driver. With barge-mounted pile driver, Manson Construction embarked on its journey into marine construction and eventually dredging, a journey which continues today as it has become a dominant player today in the U.S. maritime market, playing a crucial role in building and maintaining the nation’s maritime infrastructure.

- A Half-Billion Dollar Company

While Manson Construction started as a small pile-driving operation, it has evolved and grown into a $500 million enterprise in 2025, with a pivotal moment coming in 2012 when it flipped to a 100% employee-owned company.

Fred Paup today serves as EVP and Chairman of the Board of the company his great-grandfather founded, joining the company in 1992 and playing a key role in its growth, helping to expand operations while maintaining the company’s core values.

Operating primarily in the U.S., Manson specializes in heavy civil marine construction and dredging, with a fleet equipped for various dredging techniques, including cutter suction, clamshell, and hopper dredging. With headquarters in Seattle and regional offices across the country, the company remains strategically positioned to serve key U.S. waterways.

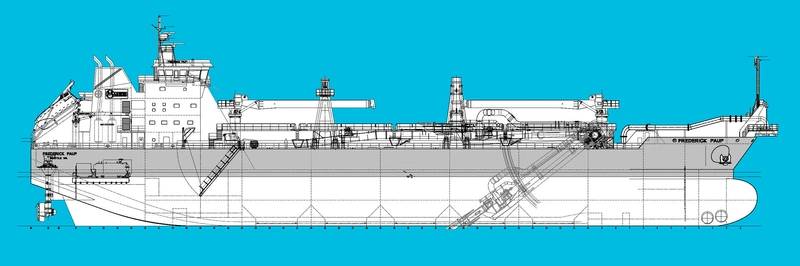

Frederick Paup, “The Bionic Man” of Dredges, is a 15,000-cu.-yd. hopper dredge beast that will be on the water and working around the U.S. later this year. Image courtesy Wabtec/Manson Contruction

Frederick Paup, “The Bionic Man” of Dredges, is a 15,000-cu.-yd. hopper dredge beast that will be on the water and working around the U.S. later this year. Image courtesy Wabtec/Manson Contruction

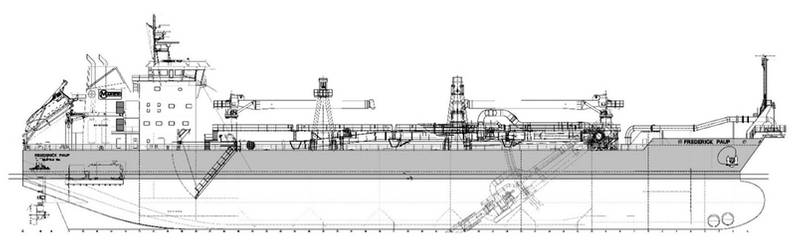

The new 15,000 cu. yd. capacity Frederick Paup will deliver later in 2025. Image courtesy Manson Contruction

The new 15,000 cu. yd. capacity Frederick Paup will deliver later in 2025. Image courtesy Manson Contruction

- Frederick Paup: “The Bionic Man” of Dredges

The Frederick Paup is a massive new hopper dredge that Paup believes will redefine efficiency and capability in the dredging industry. Currently being finished at Seatrium AmFELS in Texas, this 15,000-cubic-yard hopper dredge is the largest ever constructed by Manson and marks a significant leap forward in dredging performance. Key Features of the Frederick Paup include:

- Increased Capacity: At 420 feet long and 81 feet wide, it surpasses the Glenn Edwards, Manson’s previous largest hopper dredge.

- Advanced Power System: Featuring Tier 4 Wabtec diesel-electric engines, the dredge is more fuel-efficient and environmentally friendly, eliminating the need for urea treatment to hit emission targets.

- Enhanced Safety and Crew Comfort: The design includes improved below-deck passageways, reducing exposure to harsh weather conditions.

- Superior Pumping Capabilities: Equipped with in-hull pumps for more efficient beach nourishment and land reclamation projects.

Expected to enter service in 2025, the Frederick Paup will begin operations in Mobile Harbor and the Mississippi River, reinforcing Manson’s strong presence in the dredging sector.

“The Frederick Paup is years of experience and knowledge that Manson has built up with our hopper dredge Glenn Edwards,” said Paup, referencing the 2006-built and delivered Glenn Edwards a 13,000-cubic-yard dredge.

“The Frederick Paup is like the bionic man of dredges: she's bigger [15,000 yards versus 13,000 cubic yards]; she's faster, her hull form has been modified [so she measures] 420 feet long by 81 feet wide,” said Paup.

A key lesson learned came in the aftermath of Superstorm Sandy, when Manson was working offshore New Jersey in February, putting two million cubic yards of sand back on the beach. Keeping workers out of the such conditioned as much as possibe was a priority with the new Frederick Paup, and with the new ships “we made it to where our crew can go bow to stern and still be below deck.

The new Wabtec powerplants were also an upgrade, as Paup explains “one of the benefits of engines being more modern, they will be more fuel efficient, and their footprint isn't quite as big.”

But the benefits don’t stop there, as Paup explained. “We could have gotten engines where you use urea to get to Tier 4 emission levels, but we didn't want to do that. We've done that before on one of our cutter section dredges … before we repowered it for the third time to meet air quality requirements and we knew that we didn't want that again. The complexity and the cost for doing diesel-electric versus straight diesel is a lot of money but,” but that is made up over time in fuel, environmental benefits, and efficiency.

“So, we will be the Cookie Monster of dredges, eating up the work like crazy … we’ll be coming to a harbor near you soon,” said Paup.

“We could have gotten engines where you use urea to get to Tier 4 emission levels, but we didn't want to do that," said Fred Paup. Image courtesy Wabtec/Manson Contruction

“We could have gotten engines where you use urea to get to Tier 4 emission levels, but we didn't want to do that," said Fred Paup. Image courtesy Wabtec/Manson Contruction

- The Jones Act & a Level Playing Field

The Jones Act has been, and will continue to be a hotly debated requirement for operating in U.S. waters, and Manson Construction’s adherence to the Jones Act is not just a legal obligation—it is a fundamental commitment to national security, economic stability, and the preservation of American maritime jobs according to Paup, as the law ensures that domestic maritime commerce remains in American hands, protecting the nation’s supply chains and bolstering its shipbuilding industry.

For Paup and Manson Construction, the Jones Act guarantees a level playing field and supports a robust, skilled maritime workforce.

“For us, it's about an even playing field. If it's going to cost me X dollars per day for a US shipyard, then I want my competitor to have that same thing,” said Paup. “I like to say ‘you can demand that I have a goat on the deck of a dredge as a requirement, so long as my competitor has to have a goat on the deck of their dredge, I'm okay with it; that's fine. Just be consistent.”

“The Jones Act ensures that we maintain a strong domestic maritime industry,” says Fred Paup. “Without it, we would see an influx of foreign-flagged vessels undercutting U.S. operators, leading to job losses and a decline in shipbuilding capacity. We take pride in constructing and crewing our vessels in the U.S., and we stand against any efforts to undermine these protections.”

Despite occasional challenges from foreign interests seeking exemptions, bipartisan congressional support has preserved the Jones Act’s role in protecting U.S. maritime operations. The law plays a critical role in national defense, ensuring that the country maintains a fleet of vessels and trained mariners ready to support military logistics in times of crisis. In an era of global uncertainty, maintaining a domestic maritime industry is more crucial than ever.

San Gabriel to Newport Bay (Surfside-Sunset) Stage 13 Beach Nourishment. Image courtesy Manson Construction

San Gabriel to Newport Bay (Surfside-Sunset) Stage 13 Beach Nourishment. Image courtesy Manson Construction

- Investing in the Future: Vessels and Workforce

Beyond the Frederick Paup, Manson is planning additional investments, including a new 30-inch ABS offshore cutter suction dredge, designed by C-Job, for Gulf of Mexico operations. These expansions align with the company’s long-term strategy of strengthening U.S. dredging capabilities.

A key component of this strategy is workforce development. Manson has proactively trained additional crew members across its fleet to ensure a seamless transition when the Frederick Paup begins operations. With industry wages rising—50% of Manson employees now earn over $100,000 annually—the company remains a competitive employer in the maritime sector.

Watch the full interview with Fred Paup, Manson Construction, on the Maritime Matters: The MarineLink Podcast: