First of Five Maersk Tankers’ Vessels Fitted with bound4blue Suction Sails (Video)

Wind propulsion specialist bound4blue has completed the first installation under its agreement with Maersk Tankers, fitting four 24-meter eSAIL suction sails on the medium-range tanker Maersk Trieste as part of a wider fleet retrofit program.The installation marks the first phase of a contract agreed in December 2024 covering 20 eSAIL units across five Maersk Tankers MR vessels, representing bound4blue’s largest order to date.The four eSAIL units were installed at EDR Shipyard in Belgium following preparatory work carried out at Yiu Lian Shipyard in Shenzhen, China.

Boston's Cathleen Stone Island Ferry Undergoes Refit

Boston Harbor's MV Outward Bound has returned to Gladding-Hearn Shipbuilding, Duclos Corporation for a mid-life refit. Redelivery is planned for spring 2026. Purpose-designed by JW Gilbert Associates and built by the Somerset, Mass., shipyard in 1995, the 64-foot, 140-passenger steel vessel carries visitors and supplies seasonally to Cathleen Stone Island Outward Bound, which offers experiential outdoor programs for youth and adults on the island in Boston Harbor.Along with installing a new shaft and propeller…

ABS Offers Best Practice for Energy Efficiency Retrofits

The latest analysis from ABS, Retrofits for Energy and Emissions Improvements, provides critical insights into the impact of retrofitting, including classification and statutory requirements, as well as best practices for implementation.The report builds upon the conclusions presented in the ABS 2025 Outlook, Beyond the Horizon: Vision Meets Reality. With an array of retrofit options available, each offering potential improvements dependent on a range of factors, the report provides…

UK Funds BlueNose Project to Develop Vessel Aerodynamic Retrofits

BlueNose, a London-based maritime innovation startup, has been awarded $460,000 through the U.K. Government’s Clean Maritime Demonstration Competition (CMDC6) to advance aerodynamic efficiency concepts for commercial shipping.The seven-month feasibility study, funded under the Department for Transport’s UK SHORE program and delivered by Innovate UK, will support Project WAVE and run until March 2026. BlueNose, working with lomarlabs, will develop inflatable and foldable wind-deflector…

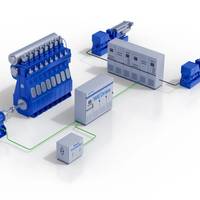

Goltens, WE Tech Partner Up on Energy-Efficient Marine Retrofits

Goltens Worldwide and Finland’s WE Tech Solutions have signed a memorandum of understanding (MOU) to promote and deliver advanced marine retrofit projects aimed at improving vessel energy efficiency and cutting emissions.Under the agreement, Goltens will act as WE Tech’s preferred global retrofit partner, supporting the rollout of the Finnish company’s energy-optimization technologies across the commercial shipping fleet.“Goltens brings global reach, outstanding technical capability, and a trusted track record in large-scale retrofit execution.

Newlight Completes RINA FAT for Hydrogen Retrofit

Newlight has completed Factory Acceptance Testing (FAT) for its hydrogen retrofit package for two- and four-stroke main engines.The system allows existing diesel engines to operate on a blend of hydrogen and conventional fuel, reducing carbon emissions without the need to replace the entire engine.Designed and built to the International Code of Safety for Ship Using Gases or Other Low Flashpoint Fuels Code (IGF Code) and validated to RINA Class Rules for hydrogen fueled ships…

Concordia Damen Begins Refit Project for Reederei Deymann Cargo Vessel

Concordia Damen has received a new contract from Reederei Deymann, one of Germany’s largest inland shipping companies, for the extensive refit of a dry cargo vessel Hirschhorn. The vessel recently arrived at the Concordia Damen yard in Werkendam, where the transformation project has now started. The refit involves the complete renewal of the aft ship. Originally equipped with a single engine, single propeller shaft and an outdated living and wheelhouse arrangement, the vessel will undergo a transformation at Concordia Damen’s yard in Werkendam.

NOAA Invests $95M in Mid-Life Vessel Renovation

The National Oceanic and Atmospheric Administration (NOAA) awarded a $95 million contract to JAG Alaska, Inc., a shipyard based in Alaska, for a mid-life renovation of the Oscar Dyson. This project not only enhances NOAA’s operational readiness but also boosts Alaska’s economy by creating skilled jobs.A highlight of the upgrade is Siemens Energy’s SISHIP BlueDrive PlusC low-voltage direct current (LVDC) propulsion system, which improves fuel efficiency and reduces emissions. The system minimizes specific fuel consumption (g/kWh) during operations…

Robosys Automation Secures Offshore Wind Vessel Retrofit Contract

Robosys Automation, a leader in maritime autonomy, vessel control systems, and smart shipping solutions, has announced that it has secured a new contract to retrofit a 26-meter Damen 2610 Fast Crew Supplier (FCS) Twin Axe High Speed Support Vessel (HSSV), with its flagship VOYAGER AI advanced maritime autonomy software.The vessel, built in 2015 to Lloyd’s Register classification standards, is powered by twin Caterpillar C32 engines with direct drives and is equipped with an Alphatron autopilot…

Maersk Retrofits Green Technology on Time-Chartered Fleet

In a large-scale program involving 50 different shipowners, A.P. Moller - Maersk is retrofitting around 200 vessels in its time-chartered fleet. The main aim of the program is to reduce the slot cost by improving fuel efficiency and cargo-carrying capacity leading to a decrease in both cost and greenhouse gas emissions.“Our medium- and long-term chartered fleet makes up a significant proportion of our operations as well as of our total fuel consumption. By working closely with our partners…

Maersk Launches Major Retrofit Program for its Time-Chartered Fleet

A.P. Moller - Maersk (Maersk), in close collaboration with the owners, is retrofitting around 200 vessels in its time-chartered fleet as part of a large-scale program involving 50 different shipowners.The main aim of the program is to reduce the slot cost by improving fuel efficiency and cargo-carrying capacity leading to a decrease in both cost and greenhouse gas emissions.Maersk has set the target of a 35% absolute reduction in its scope 1 greenhouse gas emissions by 2030 compared to the 2022 baseline year.In total…

Synergy Marine Group Completes Conversion of LNG Vessel to FSRU

Synergy Marine Group, in partnership with Karpowership, has completed the conversion of a 125,000 m3 liquefied natural gas (LNG) carrier into a floating storage and regasification unit (FSRU), the Karadeniz LNGT Powership Americas.The vessel was delivered at Seatrium’s Admiralty Yard in Singapore, marking a significant milestone in accelerating LNG-to-power deployment.Synergy administered the conversion on a turnkey, one-stop basis, from managing design to engineering, procurement…

Corsica Linea Cuts Ferry Fuel Use by 22% with Wärtsilä Retrofit

French ferry operator Corsica Linea has achieved up to 22% fuel savings on its RoPax ferry Pascal Paoli following the installation of a retrofit package delivered by Finnish technology group Wärtsilä.The upgrade, completed in late 2024, included the installation of a twin screw controllable pitch propeller (CPP) system optimized for the ship’s operating profile, an EnergoProFin energy-saving propeller cap, and updated control systems with customized combinator curves for different…

MOL Teams Up with Kinetics for ‘World's First’ Floating Data Center

Mitsui O.S.K. Lines (MOL) has signed a Memorandum of Understanding (MoU) with Kinetics, the energy transition initiative of global floating power leader Karpowership, to jointly develop a next-generation floating data center platform.Under the MoU, the two companies will collaborate on the design, construction and deployment of a state-of-the-art data center hosted on a retrofitted vessel.The facility will be supplied with uninterrupted, dedicated power from a range of flexible sources…

bound4blue Receives Third-Party Assessed Average Daily Fuel Savings Consistent With Projections

bound4blue has underlined the business case for adopting eSAIL wind propulsion technology, with today’s release of BVS assessed operational fuel savings on the Louis Dreyfus Armateurs (LDA) owned Ville de Bordeaux Ro-Ro.The vessel, chartered by Airbus, had three 22-meter bound4blue suction sail units installed in 2024. BVS assessed the savings over a year, showing an average daily fuel saving of 1.7 metric tons, with peak savings of as much as 5.4 metric tons per day.These savings…

GLO Marine to Upgrade Hydraulic System on Bluewater’s FPSO

Retrofit specialist GLO Marine has secured hydraulic system upgrade job on Bluewater’s Haewene Brim floating production, storage and offloading (FPSO) unit, following the successful delivery of the project’s first phase.The contract builds on the collaboration between GLO Marine and Bluewater in Phase 1 of the FPSO upgrade program, where GLO Marine delivered the full feasibility and engineering scope, including detailed technical analysis, prototype validation, and a complete set of engineering deliverables.Aa part of the second phase…

Estonia to Help Finance Green Retrofits

Estonia has launched a €25 million ($28 million) government grant designed to encourage the reconstruction and greening of passenger and cargo ships, tugboats and other port and auxiliary vessels in Estonian ports.This makes Estonia one of the few countries in Europe offering direct financial support in the form of state aid for ship retrofitting. The new grant, enacted by Estonia’s Minister of Infrastructure, Kuldar Leis, provides shipowners and operators with subsidies covering 15% to 30% of eligible retrofit costs…

Foreship Supports Dual Chemistry Battery System Retrofit for Wasaline

Naval architecture and engineering consultancy Foreship is supporting Wasaline in delivering a battery upgrade on MV Aurora Botnia that will see the ferry’s energy storage capacity increase nearly sixfold. The retrofit will combine two battery chemistries in a hybrid solution that is expected to cut annual CO₂ emissions by up to 23%.Building on a long-standing relationship with Wasaline that began during the vessel’s initial design phase, Foreship provided technical and strategic support for the retrofit.

AYK Energy Strikes Biggest Retrofit Deal with Wasaline Shipping Line

Marine battery maker AYK Energy is gearing up production after striking a deal to undertake the biggest ever battery retrofit on a vessel operated by Finnish shipping line Wasaline.AYK will install a 10.4MWh battery on the hybrid-electric Ropax ferry, the Aurora Botnia, which operates a daily service between Finland and Sweden. Built in 2021, the Aurora Botnia presently operates on dual-fuel LNG/biomass engines and 2.2 MWh batteries. The upgrade to a battery system nearly five times more powerful is expected to reduce fossil energy use by around 10…

GLO Marine, VMS Group Land Multi-Vessel Retrofit Job for Tidewater

GLO Marine and VMS Group Denmark have secured a multi-vessel retrofit work for offshore support vessel operator Tidewater, expanding their role in the offshore energy sector.Covering 16 vessels across three continents, including several in U.S. waters, the retrofit program marks an important step in both companies’ strategy to provide fleet-scale retrofit solutions to the international offshore vessels market.The companies are executing a full-scope BWTS retrofit and lifecycle project management plan for Tidewater.To date…

Ulusoy Refits Power on Bulk Carrier Pair to Cut CO2 Emissions

Wärtsilä will upgrade the Wärtsilä RT-flex main engines on two bulk carrier vessels owned by Turkey-based Ulusoy Sealines. The planned engine retrofits and upgrades will extend the vessels’ operational life and improve both performance and fuel efficiency, thereby significantly reducing emissions. The orders were booked by Wärtsilä in Q4 2024 and Q1 2025.With the integration of Wärtsilä Part Load Optimization (WPLO), Intelligence Combustion Control (ICC), and Fuel Actuated Sackless Technology (FAST), a CII improvement of 5% is anticipated, equating to a 2-year extension of the CII rating.

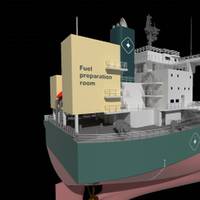

ClassNK Issues AiP for Methanol Dual Fuel Bulk Carrier Retrofit

ClassNK has issued an approval in principle (AiP) for retrofitted methanol dual fuel Kamsarmax bulk carrier developed by TSUNEISHI SHIPBUILDING and Maersk Mc-Kinney Møller Center for Zero Carbon ShippingThe AiP is for the design concept of a retrofitted Kamsarmax bulk carrier, converting it from conventional fuel to methanol dual-fuel, jointly developed by TSUNEISHI SHIPBUILDING and Fonden Maersk Mc-Kinney Møller Center for Zero Carbon Shipping.The certification demonstrates the regulatory feasibility of the ship…

Hoyer Launches Energy-Saving System for Motors

Hoyer, a leader in electric motors and automation solutions, announced the launch of Hoyer ESS (Energy-Saving System) at Sea Asia 2025 in Singapore. Specifically designed for retrofits on operating vessels, Hoyer ESS offers shipowners, operators, and fleet managers a fast-track solution to reduce motor energy consumption by 40-65% while lowering emissions and improving operational efficiency—all without the need for drydocking.With tightening environmental regulations like EEXI…