Maritime Propulsion: The NSMV Power Play

The quest to build a series of five National Security Multi-Mission Vessels (NSMVs), which will serve as training ships for five U.S. maritime academies, has drawn a broad cadre of suppliers. The powerplant was a main focus, helping to evolve the schools from steam power plants to a modern propulsion package.

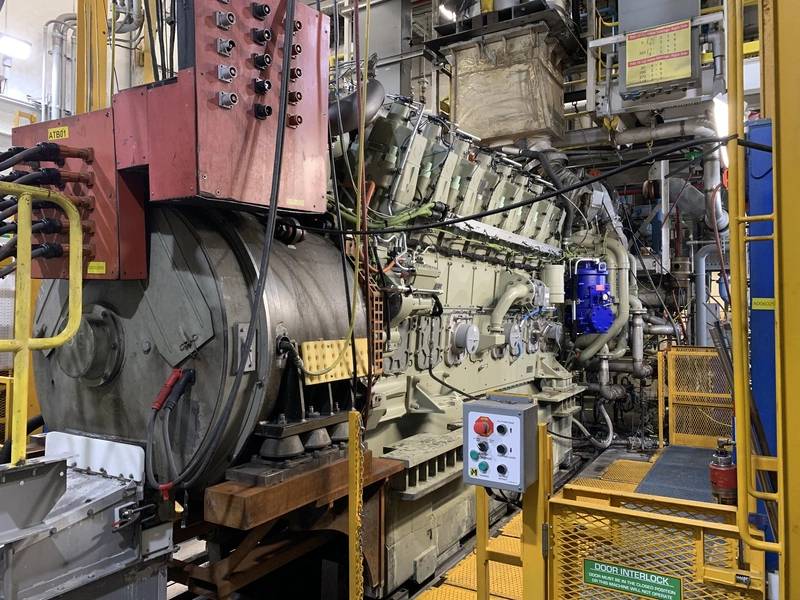

NSMVs being built for the maritime academies is widely lauded as a ‘win’ for U.S. shipbuilding, an example of commercial shipbuilding practices applied to a government shipbuilding project. Central to the long-term success of the Philly Shipyard-built NSMVs will be the performance of the ship’s power system, a modern, proven commercial solution. Anchoring the platform are Wabtec’s 16V250MDC, EPA Tier 4, IMO Tier III marine diesel engines, a total of 20 powerplants – four per ship – designed to provide the power generation for the ships’ electric grid, including the power and propulsion system.

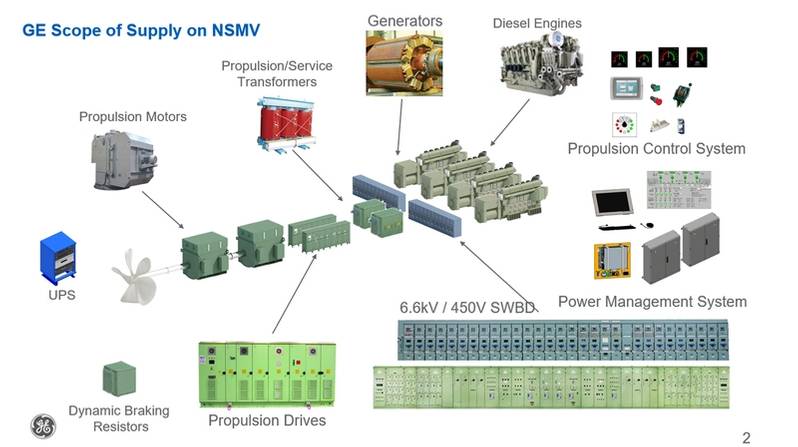

The marine diesel engines plus accessories were delivered to Wabtec channel partner Cummins Sales & Service, who in turn packaged the engines into marine gensets for the five ships. The cumulative propulsion solution is delivered by GE Power Conversion. For GE Power Conversion the NSMV program represents a more than $100m contract [which included the prime movers], signed with Philly Shipyard in July of 2020. “Normally when we deal with the US Navy, and you get the first ship and then the second ship maybe comes three, four years later,” said Steven Mankevich, Naval Business Development Director, GE Power Conversion. “In this case, we had five ships in a very short period of window.” The GE Power Conversion solution starts with the Wabtec prime movers, a company that was a former GE transportation division, which brought familiarity. Wabtec has built thousands of tier four diesel engines for trains, “so they have the capability and experience to build reliable, tier four engines without the need for scrubbers or aftertreatment. That’s a huge advantage,” said Mankevich.

“Wabtec Corporation is proud to power each of the five NSMVs for the U. S. Maritime Administration with the most advanced, fuel efficient and clean diesel engine technology in the world, built at Wabtec’s engine manufacturing facility in Grove City, Pa.,” said Tamara Gromacki, Vice President - Marine, Stationary Power and Drill, Wabtec. “Our engines maintain world class fuel efficiency while meeting the latest EPA Tier 4 emissions regulations, which reduces engine NOx emissions by 76% over previous engine models, without the use of costly aftertreatment systems.” There are four Wabtec 4.5MW engines per ship, combined with a Hyundai electric generator going to switchboards to a 6.6 kv distribution. From there, transformers convert from 6.6 kv down to 3.3 kv, and then into variable frequency drives and finally into the propulsion motors. “The propulsion motors are tandem units that sit in series, and AC induction motors connected to a shaft, which then connects to the propeller,” said Mankevich. “The beauty of the AC induction motor is that it has been around for well over a hundred years. It was invented and finalized by Nikola Tesla. There’s no doubt that the AC induction motor is still one of the most robust technologies out there because of the simplification.”

Image Courtesy GE

Image Courtesy GE

Training the Next Generation

As described in the previous story, part of the beauty of the new training ships and modern equipment outfit will be the ability to train cadets on the equipment they are likely to see when rotating out of education and into the commercial market. “This will be the first time that an EPA Tier 4 Certified Engine, from any OEM, will be installed into a newbuild government-owned vessel,” said Gromacki. “A unique aspect of this project is that the Maritime School of Engineering will include Wabtec’s EGR Clean Diesel Engine Technology as part of its curriculum, permitting graduating cadets to have a very good understanding of our technology.”

She said Wabtec is working with MarAd, Tote, and the maritime academies to provide a practical and efficient training program, including online and hands-on Wabtec Engine University Training, and in-plant (engine design overview and manufacturing process) tours for students and staff.

Looking at the propulsion system wholistically, Mankevich said “as with any ship, there’s always going to be the need for maintenance and upgrades. But with the electric drives, the long-term maintenance is altered in part because the biggest antiquity item will be the computer chips.” Another focal point for training is safe operation of the onboard electrical system, ensuring the system is de-powered and access per plan.

“We’ve gone through several training courses and we’ll be training the crew on how to maintain it, how to clean it the proper way to, and of course we’re using 6.6 kv,” said Mankevich. He said the drives are designed to help minimize the chance of electric shock, smartly designed so that if a locked door is opened, the drives shut down.

“However, there are more than just bus bars and electronic equipment,” said Mankevich. “You have capacitors, which are nothing more than the batteries. So at times you will still have residual charges inside there.” To that end there’s a whole regimen of training on de-energizing the system, inclduding using resistive elements to drain all the capacitors so that in the event somebody goes in and touches something, that they’re not getting electric shock.” In addition, the units have QR codes, too, allowing anyone servicing the unit to scan the code to view a video on accessing the unit safely.

Photo courtesy Wabtec

Photo courtesy Wabtec